Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature

Abstract

:1. Introduction

2. The Assessed Documents

- LCA of batteries used in automotive applications, rejecting all the papers that analyze batteries in other contexts (e.g., for stationary use).

- Documents assessing a specific battery life cycle phase, for example, production or end of life and recycling phase, and identifying materials and operations with relevant environmental impacts.

- Studies comparing different battery models, characterized by different chemistry, power, energy density and storage capacity.

- Automotive batteries literature reviews.

- Studies assessing a single battery model and identifying the major impacts due to materials and operations, suggesting sustainable alternatives.

3. Goal and Scope

3.1. Functional Unit

3.2. System Boundaries

3.3. Allocation System

3.4. Cut-Off Rules

3.5. Impact Categories and Methods

4. Life Cycle Inventory—LCI

5. Life Cycle Impact Assessment—LCIA

6. Sensitivity and Uncertainty Analysis

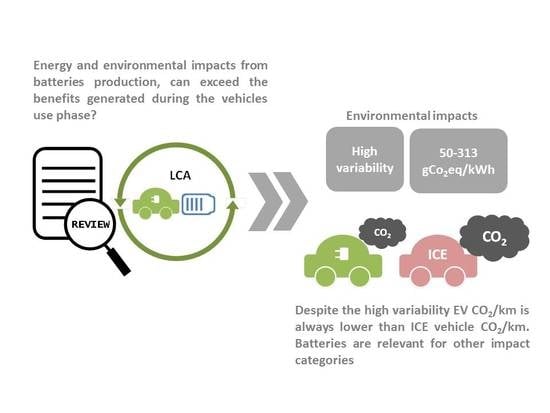

7. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Girardi, P.; Gargiulo, A.; Brambilla, P.C. A comparative LCA of an electric vehicle and an internal combustion engine vehicle using the appropriate power mix: The Italian case study. Int. J. Life Cycle Assess. 2015, 20, 1127–1142. [Google Scholar] [CrossRef]

- Valverde, V.; Clairotte, M.; Bonnel, P.; Giechaskiel, B.; Carriero, M.; Otura, M.; Suarez-Bertoa, R. Joint Research Centre 2018 Light-Duty Vehicles Emissions Testing; JRC117625; Publications Office of the European Union: Luxembourg, 2019. [Google Scholar]

- Girardi, P.; Brambilla, P.C.; Mela, G. Life Cycle Air Emissions External Costs Assessment for Comparing Electric and Traditional Passenger Cars. Integr. Environ. Assess. Manag. 2020, 16, 140–150. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Nordelöf, A.; Messagie, M.; Tillman, A.M.; Söderman, M.L.; Van Mierlo, J. Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—what can we learn from life cycle assessment? Int. J. Life Cycle Assess. 2014, 19, 1866–1890. [Google Scholar] [CrossRef] [Green Version]

- Gao, L.; Winfield, Z.C. Life cycle assessment of environmental and economic impacts of advanced vehicles. Energies 2012, 5, 605–620. [Google Scholar] [CrossRef]

- Feng, S.; Magee, C.L. Technological development of key domains in electric vehicles: Improvement rates, technology trajectories and key assignees. Appl. Energy 2020, 260, 114264. [Google Scholar] [CrossRef]

- Cusenza, M.A.; Bobba, S.; Ardente, F.; Cellura, M.; Di Persio, F. Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles. J. Clean. Prod. 2019, 215, 634–649. [Google Scholar] [CrossRef] [PubMed]

- Helmers, E.; Weiss, M. Advances and critical aspects in the life-cycle assessment of battery electric cars. Energy Emiss. Control Technol. 2017, 5, 1. [Google Scholar] [CrossRef] [Green Version]

- Ioakimidis, C.S.; Murillo-Marrodán, A.; Bagheri, A.; Thomas, D.; Genikomsakis, K.N. Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios. Sustainability 2019, 11, 2527. [Google Scholar] [CrossRef] [Green Version]

- Ellingsen, L.A.W.; Majeau-Bettez, G.; Singh, B.; Srivastava, A.K.; Valøen, L.O.; Strømman, A.H. Life cycle assessment of a lithium-ion battery vehicle pack. J. Ind. Ecol. 2014, 18, 113–124. [Google Scholar] [CrossRef] [Green Version]

- Notter, D.A.; Gauch, M.; Widmer, R.; Wager, P.; Stamp, A.; Zah, R.; Althaus, H.J. Contribution of Li-ion batteries to the environmental impact of electric vehicles. Environ. Sci. Technol. 2010, 44, 6550–6556. [Google Scholar] [CrossRef] [PubMed]

- Romare, M.; Dahllöf, L. The life cycle energy consumption and greenhouse gas emissions from lithium-ion batteries. Stockholm Zugriff Am 2017, 23. Available online: https://www.ivl.se/download/18.5922281715bdaebede9559/1496046218976/C243+The+life+cycle+energy+consumption+and+CO2+emissions+from+lithium+ion+batteries+.pdf (accessed on 30 March 2020).

- Dunn, J.B.; Gaines, L.; Barnes, M.; Sullivan, J.L.; Wang, M. Material and Energy Flows in the Materials Production, Assembly, and End-of-Life Stages of the Automotive Lithium-Ion Battery Life Cycle; Argonne: Lemont, IL, USA, 2014. [Google Scholar]

- Amarakoon, S.; Smith, J.; Segal, B. Application of Life-Cycle Assessment to Nanoscale Technology: Lithium-Ion Batteries for Electric Vehicles; No. EPA 744-R-12-001; Environmental Protection Agency: Washington, DC, USA, 2013. [Google Scholar]

- ReCharge. PEFCR—Product Environmental Footprint Category Rules for High Specific Energy Rechargeable Batteries for Mobile Applications; Recharge: Brussels, Belgium, 2018. [Google Scholar]

- Richa, K.; Babbitt, C.W.; Nenadic, N.G.; Gaustad, G. Environmental trade-offs across cascading lithium-ion battery life cycles. Int. J. Life Cycle Assess. 2017, 22, 66–81. [Google Scholar] [CrossRef]

- Faria, R.; Marques, P.; Garcia, R.; Moura, P.; Freire, F.; Delgado, J.; de Almeida, A.T. Primary and secondary use of electric mobility batteries from a life cycle perspective. J. Power Sources 2014, 262, 169–177. [Google Scholar] [CrossRef]

- Oliveira, L.; Messagie, M.; Rangaraju, S.; Sanfelix, J.; Rivas, M.H.; Van Mierlo, J. Key issues of lithium-ion batteries–from resource depletion to environmental performance indicators. J. Clean. Prod. 2015, 108, 354–362. [Google Scholar] [CrossRef]

- Liu, C.; Lin, J.; Cao, H.; Zhang, Y.; Sun, Z. Recycling of spent lithium-ion batteries in view of lithium recovery: A critical review. J. Clean. Prod. 2019, 228, 801–813. [Google Scholar] [CrossRef]

- Peters, J.F.; Baumann, M.; Zimmermann, B.; Braun, J.; Weil, M. The environmental impact of Li-Ion batteries and the role of key parameters–A review. Renew. Sustain. Energy Rev. 2017, 67, 491–506. [Google Scholar] [CrossRef]

- Majeau-Bettez, G.; Hawkins, T.R.; Strømman, A.H. Life cycle environmental assessment of lithium-ion and nickel metal hydride batteries for plug-in hybrid and battery electric vehicles. Environ. Sci. Technol. 2011, 45, 4548–4554. [Google Scholar] [CrossRef] [PubMed]

- Dai, Q.; Kelly, J.C.; Gaines, L.; Wang, M. Life cycle analysis of lithium-ion batteries for automotive applications. Batteries 2019, 5, 48. [Google Scholar] [CrossRef] [Green Version]

- ISO—The International Organization for Standardization. ISO 14040:2006: Environmental Management—Life Cycle Assessment—Principles and Framework; ISO—The International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- ISO—The International Organization for Standardization. ISO 14044:2006: Environmental Management—Life Cycle Assessment—Requirements and Guidelines; ISO—The International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- European Commission—Joint Research Centre—Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook—Recommendations for Life Cycle Impact Assessment in the European Context, 1st ed.; EUR 24571 EN; Publications Office of the European Union: Luxembourg, 2011. [Google Scholar]

- Ellingsen, L.; Hung, C.; Strømman, A. Identifying key assumptions and differences in life cycle assessment studies of lithium-ion traction batteries with focus on greenhouse gas emissions. Transp. Res. Part D Transp. Environ. 2017, 55, 82–90. [Google Scholar] [CrossRef]

| Title | ||

|---|---|---|

| Bibliographic reference | Bibliographic reference following the APA style (American Psychological Association). | |

| Goal and Scope | Target of the study | Specify the target of the study; specify if the LCA is attributional or consequential (if possible). |

| Functional unit | Specify the functional unit considered and evaluate whether it is suitable to represent the service analyzed. | |

| System boundaries | Specify the system boundaries and the phases of the analysis considered. Possibly, state the omitted phases and the reason for their exclusion. | |

| Allocation system | Indicate any allocation system used (mass, economic, etc.,) and how the end of life is managed (cut-off, default, system expansion). | |

| Cut-off rules | Specify any cut-off rules and the parameters considered. | |

| Impact categories and methods | Indicate impact categories and methods used in the study. | |

| Inventory—LCI | Data source | Report data source, specifying if primary or secondary data are considered. |

| LCIA | Results | Summarize the results of the study. |

| Sensitivity and uncertainty analysis | Considered parameters and techniques | Specify parameters and techniques considered to realize sensitivity and uncertainty analysis (if present). |

| Conclusions | Main conclusions of the study | Summarize the main conclusions of the document. |

| Authors | Title | Year | Type of Document |

|---|---|---|---|

| Cusenza, M, A; Bobba, S; Ardente, F; Cellura, M; Di Persio, F | Energy and environmental assessment of a traction lithium-ion battery pack for plug-in hybrid electric vehicles [7] | 2019 | Journal paper |

| Helmers, E; Weiss, M | Advances and critical aspects in the life-cycle assessment of battery electric cars [8] | 2017 | Journal paper |

| Ioakimidis, C, S; Murillo-Marrodàn, A; Bagheri, A; Thomas, D; Genikomaskis, K | Life Cycle Assessment of a Lithium Iron Phosphate (LFP) Electric Vehicle Battery in Second Life Application Scenarios [9] | 2019 | Journal paper |

| Ellingsen, L, A, W; Majeau-Bettez, G; Singh, B; Srivastava, A, K; Valøen, L, O; Strømman, A, H | Life Cycle Assessment of a Lithium-Ion Battery Vehicle Pack [10] | 2014 | Journal paper |

| Notter, D, A; Gauch, M; Widmer, R; Wager, P; Stamp, A; Zah, R; Althaus, H, J | Contribution of Li-ion batteries to the environmental impact of electric vehicles [11] | 2010 | Journal paper |

| Romare, M; Dahllöf, L | The Life Cycle Energy Consumption and Greenhouse Gas Emissions from Lithium-Ion Batteries [12] | 2017 | Technical report |

| Dunn, J, B; Gaines, L; Barnes, M; Sullivan, J | Material and Energy Flows in the Materials Production, Assembly, and End-of-Life Stages of the Automotive Lithium-Ion Battery Life Cycle [13] | 2014 | Technical report |

| Amarakoon, S; Smith, J; Segal, B | Application of Life-Cycle Assessment to Nanoscale Technology: Lithium-ion Batteries for Electric Vehicles [14] | 2013 | Technical report |

| ReCharge | PEFCR - Product Environmental Footprint Category Rules For High Specific Energy Rechargeable Batteries for Mobile Applications [15] | 2018 | Technical guide |

| Nordelöf, A; Messagie, M; Tillman, A. M; Söderman, M. L; Van Mierlo, J | Environmental impacts of hybrid, plug-in hybrid, and battery electric vehicles—what can we learn from life cycle assessment? [4] | 2014 | Journal paper |

| Richa, K; Babbitt, C. W; Nenadic, N, G; Gaustad, G | Environmental trade-offs across cascading lithium-ion battery life cycles [16] | 2017 | Journal paper |

| Faria, R; Marques, P; Garcia, R; Moura, P; Freire, F; Delgado, J; de Almeida, A, T | Primary and secondary use of electric mobility batteries from a life cycle perspective [17] | 2014 | Journal paper |

| Oliveira, L; Messagie, M; Rangaraju, S; Sanfelix, J; Rivas, M, H; Van Mierlo, J | Key issues of lithium-ion batteries–from resource depletion to environmental performance indicators [18] | 2015 | Journal paper |

| Liu, C; Lin, J; Cao, H; Zhang, Y; Sun, Z | Recycling of spent lithium-ion batteries in view of lithium recovery: A critical review [19] | 2019 | Journal paper |

| Peters, J, F; Baumann, M; Zimmermann, B; Braun, J; Weil, M | The environmental impact of Li-Ion batteries and the role of key parameters–A review [20] | 2017 | Journal paper |

| Majeau-Bettez, G; Hawkins, T, R; Strømman, A, H | Life Cycle Environmental Assessment of Lithium-Ion and Nickel Metal Hydride Batteries for Plug-In Hybrid and Battery Electric Vehicles [21] | 2011 | Journal paper |

| Dai, Q; Kelly, J, C; Gaines, L.; Wang, M | Life Cycle Analysis of Lithium-Ion Batteries for Automotive Applications [22] | 2019 | Journal paper |

| Vehicle Production | Battery Production | Maintenance | Road | Fuel/Electricity Production | Use | Total | |||

|---|---|---|---|---|---|---|---|---|---|

| g CO2eq /km | (w/out battery) | Min | Max | IT marg. Mix | Urban Cycle | Min | Max | ||

| Diesel | 38.2 | 0.0 | 0.0 | 7.7 | 0.6 | 41.1 | 198.5 | 286.1 | 286.1 |

| Electric | 37.7 | 9.5 | 59.6 | 6.2 | 0.6 | 92.5 | 0.0 | 146.6 | 196.7 |

| Petrol | 41.5 | 0.0 | 0.0 | 7.4 | 0.5 | 59.1 | 221.6 | 330.0 | 330.0 |

| Vehicle | Vehicle Production & Disposal | Battery Production & Disposal | Fuel/Electricity Production & Supply | Use & Maintenance | Total | |||

|---|---|---|---|---|---|---|---|---|

| Impacts/km | Type | Min | Max | Min | Max | |||

| Acidification Potential | EV | 0.10 | 0.10 | 0.70 | 0.23 | 0.02 | 0.46 | 1.00 |

| g SO2 eq | ICE | 0.14 | - | - | 0.55 | 0.11 | 0.79 | 0.79 |

| Eutrophication Potential | EV | 0.06 | 0.01 | 0.12 | 0.06 | 0.01 | 0.27 | 0.25 |

| g PO4 eq | ICE | 0.06 | - | - | 0.07 | 0.03 | 0.16 | 0.16 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Temporelli, A.; Carvalho, M.L.; Girardi, P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies 2020, 13, 2864. https://doi.org/10.3390/en13112864

Temporelli A, Carvalho ML, Girardi P. Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature. Energies. 2020; 13(11):2864. https://doi.org/10.3390/en13112864

Chicago/Turabian StyleTemporelli, Andrea, Maria Leonor Carvalho, and Pierpaolo Girardi. 2020. "Life Cycle Assessment of Electric Vehicle Batteries: An Overview of Recent Literature" Energies 13, no. 11: 2864. https://doi.org/10.3390/en13112864