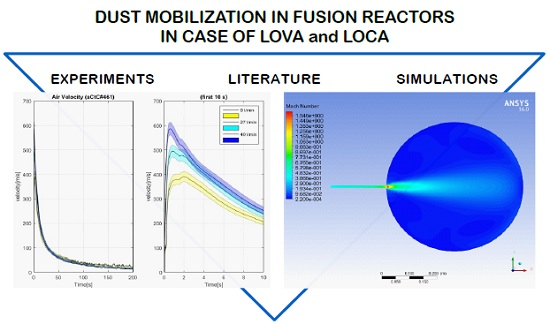

A Review of Dangerous Dust in Fusion Reactors: from Its Creation to Its Resuspension in Case of LOCA and LOVA

Abstract

:1. Introduction

2. Dust in Fusion Nuclear Reactors

2.1. Materials based on carbon

- (1)

- “A good compatibility with a wide variety of plasma operation conditions.”

- (2)

- “A good thermo-mechanical properties of carbon fiber composites (CFC) and the lack of melting under transient power fluxes makes these materials compatible with high power flux plasmas.”

- (3)

- “A high density plasmas in ITER-like regimes were obtained in the experiments with a relatively low core contamination (Zeff = 1.5–2.0).”

- (4)

- “Due to its Low-Z, the core radiative losses associated with C in high temperature plasmas are low, while the divertor radiative losses by C, which are necessary to maintain semi-detached operation in ITER, can decrease the divertor power flux by more than a factor of ∼2 compared with fully attached conditions.“

- (1)

- High erosion trend.

- (2)

- High tritium retention levels

2.2. Material Based on Beryllium

2.3. Materials with High-Z

2.4. Austenitic and Ferritic/Martensitic Steels and Other Advanced Materials

3. Materials and Methods

- static pressure inside the chamber (Pa),

- average temperature of the chamber (K),

- air volume flow-rate in liters per minute (L/min),

- differential pressure from transducers in selected locations (Pa), local air velocity (m/s) and corresponding Mach Number (Ma).

- -

- Ratio of the fluid specific heat at constant pressure to the fluid specific heat at constant volume (it is approximately equal to 1.4 for air at standard condition);

- -

- Universal gas constant;

- -

- Dry air molecular mass at standard conditions.

- -

- Mean temperature in the transducer’s positions from i thermocouples (K);

- -

- (Pa) Static pressure (measured by Pirani pressure gauge);

- -

- (Pa) Differential pressure (measured by pressure transducers as difference between its head pressure and its reference tube pressure);

- -

- (Pa) Total pressure (measured by the transducers head).

4. Results and Discussion

4.1. Experimental Campaign

- Flow rate measures (through the flow meters)

- Pressure rates (through pressure gauges)

- Temperatures rates (through thermocouples)

- Punctual velocity values (through pressure transducers)

- Experimental results get reproducing the LOCA accident through an air injection from valve C and D

- Experimental results get reproducing the LOVA accident through an air injection from valve E and F

- Initial pressure of the compressed air that has to be flowed in the facility: 2,8 bar

- Initial pressure inside the chamber: 200 Pa

- Final pressure inside the chamber: 95000 Pa

- Environmental temperature: 25 °C

- Three different inlet air flow rates:

- 8 L/min (to reproduce a pressurization rate of 100 Pa/s inside STARDUST-U)

- 27 L/min (to reproduce a pressurization rate of 300 Pa/s inside STARDUST-U as suggested by the GSSR)

- 40 L/min (to reproduce a pressurization rate of 500 Pa/s inside STARDUST-U)

4.2. Experiments from Valve C and D (LOCA Accidents Reproduction)

Experiments from Valve E and F (LOVA Accidents Reproduction)

4.3. Numerical Simulations

4.3.1. Numerical Simulation from Valve C (LOCA Accidents Reproduction)

- Subsonic incompressible regime: Ma < 0,2–0,3

- Subsonic regime: Ma < 1

- Transonic regime: 0,8 < Ma < 1,2

- Sonic regime: Ma = 1

- Supersonic regime: Ma > 1

- Hypersonic regime: Ma > 5” [149]

4.3.2. Numerical Simulation from Valve E and F (LOVA Accidents Reproduction)

4.4. Comparison between by Experimental Results and Numerical Simulations

- : macroscopic velocity of the object considered [m/s],

- a: velocity of sound in the fluid considered [m/s],

- : adiabatic coefficient [aim.],

- R: specific gas constant [J kg−1 K−1],

- T: absolute temperature [K].” [149]

5. Conclusions

- initial pressure of 200 Pa;

- final pressure of 95000 Pa;

- room temperature.

- While the following conditions were changed:

- the flow rate with value of 8 L/min, 27 L/min, 40 L/min;

- the transducers position: C and D;

- valve air inlet: C and D.

- Time ≅ 2–3 s; Velocity ≅ 500 m/s flow rate = 40 L/min;

- Time ≅ 2–3 s; Velocity ≅ 470 m/s flow rate = 27 L/min;

- Time ≅ 2–3 s; Velocity ≅ 350 m/s flow rate = 8 L/min.

- Time ≅ 2–3 s; Velocity ≅ 550 m/s flow rate = 40 L/min;

- Time ≅ 2–3 s; Velocity ≅ 500 m/s flow rate = 27 L/min;

- Time ≅ 2–3 s; Velocity ≅ 350 m/s flow rate = 8 L/min.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nuttall, W.J. Fusion as an Energy Source; Institute of Physics: London, UK, 2008; Available online: https://www.iop.org/publications/iop/2008/file_38224.pdf (accessed on 18 April 2016).

- European Commission. Fusion Research an Energy Option for Europe’s Future; Office for Official Publications of the European Communities: Luxembourg, 2007; Available online: https://ec.europa.eu/research/energy/pdf/92-79-00513-8_en.pdf (accessed on 18 April 2016).

- Redd, N.T. What is Fusion? 2012. Available online: http://www.livescience.com/23394-fusion.html (accessed on 19 July 2016).

- Brumfiel, G. Fusion Dreams Delayed—Nature. Available online: http://www.nature.com/news/2009/090527/full/459488a.html (accessed on 20 July 2016).

- Sharpe, J.P.; Petti, D.A.; Bartels, H.W. A review of dust in fusion devices: Implications for safety and operational performance. Fusion Eng. Des. 2002, 63–64, 153–163. [Google Scholar] [CrossRef]

- Winter, J. Dust: A new challenge in nuclear fusion research? Phys. Plasmas 2002, 7, 3862–3866. [Google Scholar] [CrossRef]

- Malizia, A.; Lupelli, I.; Richetta, M.; Gelfusa, M.; Bellecci, C.; Gaudio, P. Safety Analysis in Large Volume Vacuum Systems Like Tokamak: Experiments and Numerical Simulation to Analyse Vacuum Ruptures Consequences. Adv. Mater. Sci. Eng. 2014, 2014, 1–29. [Google Scholar] [CrossRef]

- Federici, G.; Skinner, C.H.; Brooks, J.N.; Coad, J.P.; Grisolia, C.; Haasz, A.A.; Hassanein, A.; Philipps, V.; Pitcher, C.S.; Roth, J.; et al. Plasma-material interactions in current tokamaks and their implications for next step fusion reactors. Nucl. Fusion 2001, 41, 1967–2137. [Google Scholar] [CrossRef]

- Federici, G.; Andrew, P.; Barabaschi, P.; Brooks, J.; Doerner, R.; Geier, A.; Herrmann, A.; Janeschitz, G.; Krieger, K.; Kukushkin, A.; et al. Key ITER plasma edge and plasma-material interaction issues. J. Nucl. Mater. 2003, 313–316, 11–22. [Google Scholar] [CrossRef]

- ITER. Radiological and Energy Source Terms. Generic Site Safety Report, Vol. III, G 84 RI 3 01-07-13 R1.0 Garching JWS. 2001. Available online: https://fusion.gat.com/iter/iter-fdr/final-report-sep-2001/Plant_Assembly_Documents_(PADs)/Generic_Site_Safety_Report_GSSR/GSSR_03_Rad+EnergySources.pdf (accessed on 18 April 2016).

- Jin, X.Z.; Bachmann, C.; Porfiri, M.T.; Federici, G. Source terms and critical event sequences for the blanket concept HCPB. Report for Task Agreement, EFDA_D_2L8RZY v3.0-WP13-SYS04-T03. 2014. Available online: https://idm.euro-fusion.org/?uid=2L8RZY (accessed on 18 April 2016).

- Jin, X.Z.; Bachmann, C.; Porfiri, M.T.; Federici, G. Source terms and critical event sequences for two DEMO blanket concepts HCPB and HCLL. Report for Task Agreement, EFDA_D_2LDAL4 V2.0-WP13-SYS04-T03. 2014. Available online: https://idm.euro-fusion.org/?uid=2KX64M (accessed on 18 April 2016).

- Di Giovanni, D.; Luttazzi, E.; Marchi, F.; Latini, G.; Carestia, M.; Malizia, A.; Gelfusa, M.; Fiorito, R.; D’Amico, F.; Cenciarelli, O.; et al. Two realistic scenarios of intentional release of radionuclides (Cs-137, Sr-90)—The use of the HotSpot code to forecast contamination extent. WSEAS Trans. Environ. Dev. 2014, 10, 106–122. [Google Scholar]

- Malizia, A.; Lupelli, I.; D’Amico, F.; Sassolini, A.; Fiduccia, A.; Quarta, A.M.; Fiorito, R.; Gucciardino, A.; Richetta, M.; Bellecci, C.; et al. Characterisation of Carbon Dioxide Absorbent Material For Enclosed Space Applications. Def. S T Tech. Bull. 2012, 5, 36–45. [Google Scholar]

- Rondeau, A.; Merrison, J.; Iversen, J.J.; Peillon, S.; Sabroux, J.C.; Lemaitre, P.; Gensdarmes, F.; Chassefière, E. First experimental results of particle re-suspension in a low pressure wind tunnel applied to the issue of dust in fusion reactors. Fusion Eng. Des. 2015, 32, 98–99. [Google Scholar] [CrossRef]

- Sharpe, J.P.; Humrickhouse, P.W. Dust mobilization studies in the TDMX facility. Fusion Eng. Des. 2006, 81, 1409–1415. [Google Scholar] [CrossRef]

- Baluc, N.; Abe, K.; Boutard, J.L.; Chernov, V.M.; Diegele, E.; Jitsukawa, S.; Kimura, A.; Klueh, R.L.; Kohyama, A.; Kurtz, R.J.; et al. Status of R&D activities on materials for fusion power reactors. Nucl. Fusion 2007, 47, S696–S717. [Google Scholar]

- Stork, D.; Agostini, P.; Boutard, J.-L.; Buckthorpe, D.; Diegele, E.; Dudarev, S.L.; English, C.; Federici, G.; Gilbert, M.R.; Gonzalez, S.; et al. Materials R&D for a timely DEMO: Key findings and recommendations of the EU Roadmap Materials Assessment Group. Fusion Eng. Des. 2014, 89, 1586–1594. [Google Scholar]

- Boccaccini, L.V.; Hermsmeyer, S.; Fischer, U.; Ihli, T.; Janeschitz, G.; Kohly, C.; Nagy, D.; Norajitra, P.; Polixa, C.; Reinamnn, J.; et al. Studies of In-Vessel Component Integration for a Helium-Cooled Fusion Reactor. Available online: http://www-pub.iaea.org/MTCD/publications/PDF/P1250-cd/papers/ppca1-i.pdf (accessed on 18 July 2016).

- Kakudate, S.; Shibanuma, K. Rail deployment and storage procedure and test for ITER blanket remote maintenance. Fusion Eng. Des. 2003, 65, 133–140. [Google Scholar] [CrossRef]

- Raffray, A.R.; Chiocchio, S.; Ioki, K.; Krassovski, D.; Kubik, D.; Tivey, R. High heat flux thermal-hydraulic analysis of ITER divertor and blanket systems. Fusion End. Des. 1998, 39–40, 323–331. [Google Scholar] [CrossRef]

- Izard, J.B. Development of Remote Handling Technologies Tolerant to Operation Ready Fusion Reactor Conditions. Ph.D. Thesis, Tampere University of Technology, Tampere, Finland, 14 June 2013. [Google Scholar]

- Kallenbach, A.; Kaufmann, M.; Coster, D.P.; Fuchs, J.C.; Herrmann, A.; Neuhauser, J.; Schneider, R.; Borrass, K.; Bosch, H.-S.; Carlson, A.; et al. Scrape-off layer radiation and heat load to the ASDEX Upgrade LYRA divertor. Nucl. Fusion 1999, 39, 901–918. [Google Scholar] [CrossRef]

- Loarte, A.; Lipschultz, B.; Kukushkin, A.S.; Matthews, G.F.; Stangeby, P.C.; Asakura, N.; Cousnell, G.F.; Federici, G.; Kallenbach, A.; Kneger, K.; et al. Chapter 4: Power and particle control. In Nuclear Fusion; IAEA: Vienna, Austria, 2007; Volume 47. [Google Scholar]

- Loarte, A.; Saibene, G.; Sartori, R.; Riccardo, V.; Andrew, P.; Paley, J.; Fundamenski, W.; Eich, T.; Herrmann, A.; Pautasso, G.; et al. Transient heat loads in current fusion experiments, extrapolation to ITER and consequences for its operation. Phys. Scr. 2007, 2007, 222–228. [Google Scholar] [CrossRef]

- Hender, T.C. Chapter 3: MHD stability, operational limits and disruptions. In Nuclear Fusion; IAEA: Vienna, Austria, 2007; Volume 47. [Google Scholar]

- Roth, J.; Preuss, R.; Bohmeyer, W.; Brezinsek, S.; Cambe, A.; Casarotto, E.; Doerner, R.; Gauthier, E.; Federici, G.; Higashijima, S.; et al. Flux dependence of carbon chemical erosion by deuterium ions. Nucl. Fusion 2004, 44, L21–L25. [Google Scholar] [CrossRef]

- Longhurst, G.R.; Snead, L.L.; Abou-Sena, A.A. The status of beryllium research for fusion in the United States. In Proceedings of the Sixth International Workshop on Beryllium—Technology for Fusion, Miyazaki, Japan, 2 December 2003.

- Thomas, P.R.; Jet Team. Results of JET operation with beryllium. J. Nucl. Mater. 1990, 176–177, 3–13. [Google Scholar]

- Campbell, D.J.; Jet Team. Experimental comparison of carbon and beryllium as divertor target materials in JET. J. Nucl. Mater. 1997, 241–243, 379–384. [Google Scholar] [CrossRef]

- Anderl, R.A.; Causey, R.A.; Davis, J.W.; Doerner, R.P.; Federici, G.; Haasz, A.A.; Longhurst, G.; Wampler, W.R.; Wilson, K.L. Hydrogen isotope retention in beryllium for tokamak plasma-facing applications. J. Nucl. Mater. 1999, 273, 1–26. [Google Scholar] [CrossRef]

- Causey, R.A. Hydrogen isotope retention and recycling in fusion reactor plasma-facing components. J. Nucl. Mater. 2002, 300, 91–117. [Google Scholar] [CrossRef]

- Mayer, M. Codeposition of deuterium with BeO at elevated temperatures. J. Nucl. Mater. 1997, 240, 164–167. [Google Scholar] [CrossRef]

- Doerner, R.P.; Baldwin, M.J.; Causey, R.A. Beryllium-tungsten mixed-material interactions. J. Nucl. Mater. 2005, 342, 63–67. [Google Scholar] [CrossRef]

- Doerner, R.P.; Baldwin, M.J.; Conn, R.W.; Grossman, A.A.; Luckhardt, S.C.; Seraydarian, R.; Tynan, G.R.; Whyte, D.G. Measurements of erosion mechanisms from solid and liquid materials in PISCES-B. J. Nucl. Mater. 2001, 290–293, 166–172. [Google Scholar] [CrossRef]

- Doerner, R.P.; Krasheninnikov, S.I.; Schmid, K. Particle-induced erosion of materials at elevated temperature. J. Appl. Phys. 2004, 95, 4471. [Google Scholar] [CrossRef]

- Piet, S.J.; Costley, A.; Federici, G.; Heckendorn, F.; Little, R. ITER tokamak dust-limits, production, removal, surveying. In Proceedings of the 17th IEEE/NPSS Symposium on Fusion Engineering, San Diego, CA, USA, 6–10 October 1997.

- Whyte, D.G.; Davis, J.W. Tritium recovery in ITER by radiative plasma terminations. J. Nucl. Mater. 2005, 337–339, 560–564. [Google Scholar] [CrossRef]

- Loarte, A.; Saibene, G.; Sartori, R.; Campbell, D.J.; Lomas, P.J.; Matthews, G.F. A new look at JET operation with Be as plasma facing material. J. Nucl. Mater. 2005, 337–339, 816–820. [Google Scholar] [CrossRef]

- Lingertat, J.; Tabasso, A.; Ali-Arshad, S.; Alper, B.; van Belle, P.; Borrass, K.; Clement, S.; Coad, J.P.; Monk, R. Studies of giant ELM interaction with the divertor target in JET. J. Nucl. Mater. 1997, 241–243, 402–407. [Google Scholar]

- Ciotti, M.; Ferro, C.; Maddaluno, G. Optimization of the FTU toroidal limiter shape. J. Nucl. Mater. 1992, 196–198, 725–728. [Google Scholar] [CrossRef]

- Hutchinson, I.H.; Boivin, R.; Bombarda, F.; Bonoli, P.; Fairfax, S.; Fiore, C.; Goetz, J.; Golovato, S.; Granetz, R.; Greenwald, M.; et al. First results from Alcator-C-MOD. Phys. Plasmas 1994, 1, 1511–1518. [Google Scholar] [CrossRef]

- Pospieszczyk, A.; Tanabe, T.; Philipps, V.; Sergienko, G.; Ohgo, T.; Kondo, K.; Wada, M.; Rubel, M.; Biel, W.; Kirschner, A.; et al. Operation of TEXTOR-94 with tungsten poloidal main limiters. J. Nucl. Mater. 2001, 290–293, 947–952. [Google Scholar] [CrossRef]

- Neu, R.; Dux, R.; Geier, A.; Kallenbach, A.; Pugno, R.; Rohde, V.; Bolshukhin, D.; Fuchs, J.C.; Gehre, O.; Gruber, O.; et al. Impurity behaviour in the ASDEX Upgrade divertor tokamak with large area tungsten walls. Plasma Phys. Control. Fusion 2002, 44, 811–826. [Google Scholar] [CrossRef]

- Neu, R.; Bobkov, V.; Dux, R.; Fuchs, J.C.; Gruber, O.; Herrmann, A.; Kallenbach, A.; Maier, H.; Mayer, M.; Putterich, T.; et al. Ten years of W programme in ASDEX Upgrade—Challenges and conclusions. Phys. Scr. 2009, T138, 014038. [Google Scholar] [CrossRef]

- May, M.J.; Fournier, K.B.; Goetz, J.A.; Terry, J.L.; Pacella, D.; Finkenthal, M.; Marmar, E.S.; Goldstein, W.H. Intrinsic molybdenum impurity density and radiative power losses with their scalings in ohmically and ICRF heated Alcator C-Mod and FTU tokamak plasmas. Plasma Phys. Control. Fusion 1998, 41, 45–64. [Google Scholar] [CrossRef]

- Lipschultz, B.; Pappas, D.A.; LaBombard, B.; Rice, J.E.; Smith, D.; Wukitch, S.J. A study of molybdenum influxes and transport in Alcator C-Mod. Nucl. Fusion 2001, 41, 585–596. [Google Scholar] [CrossRef]

- Apicella, M.L.; Mazzitelli, G.; Apruzzese, G.; Bracco, G.; Esposito, B.; Gabellieri, L.; Kroegler, H.; Leigheb, M.; Maddaluno, G.; Marinucci, M.; et al. Effects of wall boron coating on FTU plasma operations. J. Nucl. Mater. 2003, 313–316, 269–273. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.L.; Gonzalez de Cicente, S.M.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.F.; et al. Recent progress in research on tungsten materials for nuclear fusion applications in Europe. J. Nucl. Mater. 2013, 432, 482–500. [Google Scholar] [CrossRef]

- Rieth, M.; Dudarev, S.L.; Gonzalez de Vicente, S.M.; Aktaa, J.; Ahlgren, T.; Antusch, S.; Armstrong, D.E.J.; Balden, M.; Baluc, N.; Barthe, M.F.; et al. A brief summary of the progress on the EFDA tungsten materials program. J. Nucl. Mater. 2013, 442, S173–S180. [Google Scholar] [CrossRef]

- Pamela, J.; Bécoulet, A.; Borba, D.; Boutard, J.L.; Horton, L.; Maisonnier, D. Efficiency and availability driven R&D issues for DEMO. Fusion Eng. Des. 2009, 84, 194–204. [Google Scholar]

- Maisonnier, D.; Campbell, D.; Cook, I.; Di Pace, L.; Giancarli, L.; Hayward, J.; Li Puma, A.; Medrano, M.; Norajitra, P.; Roccella, M.; et al. Power plant conceptual studies in Europe. Nucl. Fusion 2007, 47, 1524–1532. [Google Scholar] [CrossRef]

- Norajitra, P.; Abdel-Khalik, S.I.; Giancarli, L.M.; Ihli, T.; Janeschitz, G.; Malang, S.; Mazul, I.V.; Sardain, P. Divertor conceptual designs for a fusion power plant. Fusion Eng. Des. 2008, 83, 893–902. [Google Scholar] [CrossRef]

- Janeschitz, G. Plasma-wall interaction issues in ITER. J. Nucl. Mater. 2001, 290–293, 1–11. [Google Scholar] [CrossRef]

- Bolt, H.; Barabash, V.; Federici, G.; Linke, J.; Loarte, A.; Roth, J.; Sato, K. Plasma facing and high heat flux materials-needs for ITER and beyond. J. Nucl. Mater. 2002, 307–311, 43–52. [Google Scholar] [CrossRef]

- Wittlich, K.; Hirai, T.; Compan, J.; Klimov, N.; Linke, J.; Loarte, A.; Merola, M.; Pintsuk, G.; Podkovyrov, V.; Singheiser, L.; Zhitlukhin, A. Damage structure in divertor armor materials exposed to multiple ITER relevant ELM loads. Fusion Eng. Des. 2009, 84, 1982–1986. [Google Scholar] [CrossRef]

- Hirai, T.; Pintsuk, G.; Linke, J.; Batilliot, M. Cracking failure study of ITER-reference tungsten grade under single pulse thermal shock loads at elevated temperatures. J. Nucl. Mater. 2009, 390–391, 751–754. [Google Scholar] [CrossRef]

- Roth, J.; Tsitrone, E.; Loarte, A.; Loarer, Th.; Counsell, G.; Neu, R.; Philipps, V.; Brezinsek, S.; Lehnen, M.; Coad, P.; et al. Recent analysis of key plasma wall interactions issues for ITER. J. Nucl. Mater. 2009, 390–391, 1–9. [Google Scholar] [CrossRef]

- Rieth, M.; Boutard, J.L.; Dudarev, S.L.; Ahlgren, T.; Antusch, S.; Baluc, N.; Barthe, M.F.; Becquart, C.S.; Ciupinski, L.; Correia, J.B.; et al. Review on the EFDA programme on tungsten materials technology and science. J. Nucl. Mater. 2011, 417–463, 463–467. [Google Scholar] [CrossRef]

- Rieth, M.; Hoffmann, A. Influence of microstructure and notch fabrication on impact bending properties of tungsten materials. Int. J. Refract. Met. Hard Mater. 2010, 28, 679–686. [Google Scholar] [CrossRef]

- Nemoto, Y.; Hasegawa, A.; Satou, M.; Abe, K.; Hiraoka, Y. Microstructural development and radiation hardening of neutron irradiated Mo–Re alloys. J. Nucl. Mater. 2004, 324, 62–70. [Google Scholar] [CrossRef]

- Duwe, R.; Kühnlein, W.; Münstermann, M. The new electron beam facility for materials testing in hot cells—Design and Preliminary experience. In Proceedings of the 18th Symposium on Fusion Technology, Karlsruhe, Germany, 22–26 August 1994.

- Greuner, H.; Bolt, H.; Böswirth, B.; Lindig, S.; Kuhnlein, W.; Huber, T.; Sato, K.; Suzuki, S. Vacuum plasma-sprayed tungsten on EUROFER and 316L: Results of characterisation and thermal loading tests. Fusion Eng. Des. 2005, 75, 333–338. [Google Scholar] [CrossRef]

- Maisonnier, D.; Cook, I.; Sardain, P.; Andreani, R.; Di Pace, L.; Forrest, R.; Giancarli, L.; Hermsmeyer, S.; Norajitra, P.; Taylor, N.; Ward, D. A Conceptual Study of Commercial Fusion Power Plants; Final Report of the European Fusion Power Plant Conceptual Study (PPCS). EFDA, 2005. Available online: https://www.ipp.mpg.de/ippcms/de/presse/archiv/PPCS_summary (accessed on 18 April 2016).

- Koch, F.; Bolt, H. Self passivating W-based alloys as plasma facing material for nuclear fusion. Phys. Scr. 2007, T128, 100–105. [Google Scholar] [CrossRef]

- Koch, F.; Köppl, S.; Bolt, H. Self passivating W-based alloys as plasma-facing materiatungsten l. J. Nucl. Mater. 2009, 386–388, 572–574. [Google Scholar]

- Koch, F.; Brinkmann, J.; Lindig, S.; Mishra, T.P.; Linsmeier, C. Oxidation behaviour of silicon-free tungsten alloys for use as first wall material. Phys. Scr. 2011, T145, 014019. [Google Scholar] [CrossRef]

- López-Ruiz, P.; Ordás, N.; Lindig, S.; Koch, F.; Iturriza, I.; García-Rosales, C. Self passivating bulk tungsten-based alloys manufactured by powder metallurgy. Phys. Scr. 2011, T145, 014018. [Google Scholar]

- Gonzalez, C.; Panizo-Laiz, M.; Gordillo, N.; Guerrero, C.L.; Tejado, E.; Munnik, F.; Piaggi, P.; Bringa, E.; Iglesias, R.; Gonzalez-Arrabal, R. H trapping and mobility in nanostructured tungsten grain boundaries: A combined experimental and theoretical approach. Nucl. Fusion, 2015, 55, 11. [Google Scholar] [CrossRef]

- López-Ruiz, P.; Ordás, N.; Iturriza, I.; Koch, F.; García-Rosales, C. Powder metallurgical processing of self-passivating tungsten alloys for fusion first wall application. J. Nucl. Mater. 2013, 442, S219–S224. [Google Scholar] [CrossRef]

- Neu, R.; Dux, R.; Kallenbach, A.; Putterich, T.; Balden, M.; Fuchs, J.C.; Herrmann, A.; Maggi, C.F.; O’Mullane, M.; Pugno, R.; et al. Tungsten: an option for divertor and main chamber plasma facing components in future fusion devices. Nucl. Fusion 2005, 45, 209–218. [Google Scholar] [CrossRef]

- Matějíček, J.; Chráska, P.; Linke, J. Thermal spray coatings for fusion applications—Review. J. Therm. Spray Technol. 2007, 16, 64–83. [Google Scholar] [CrossRef]

- Davis, J.W.; Slattery, K.T.; Driemeyer, D.E.; Ulrickson, M.A. Use of tungsten coatings on ITER plasma facing components. J. Nucl. Mater. 1996, 233–237, 604–608. [Google Scholar] [CrossRef]

- Bloom, E.E. The challenge of developing structural materials for fusion power systems. J. Nucl. Mater. 1998, 258–263, 7–17. [Google Scholar] [CrossRef]

- Ehrlich, K.; Bloom, E.E.; Kondo, T. International strategy for fusion materials development. J. Nucl. Mater. 2001, 283–287, 79–88. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Victoria, M.; Abe, K. Scientific and engineering advances from fusion materials R&D. J. Nucl. Mater. 2002, 307–311, 31–42. [Google Scholar]

- Bloom, E.E.; Conn, R.W.; Davis, J.W.; Gold, R.E.; Little, R.; Schultz, K.R.; Smith, D.L.; Wiffen, F.W. Low Activation Materials for Fusion Applications. University of California-Los Angeles (UCLA), UCLA Report PPG-728. 1983. Available online: http://dx.doi.org/10.1016/0022-3115(84)90570-1 (accessed on 18 April 2016).

- Mansur, L.K.; Rowcliffe, A.F.; Nanstad, R.K.; Zinkle, S.J.; Corwin, W.R.; Stoller, R.E. Materials needs for fusion, Generation IV fission reactors and spallation neutron sources—Similarities and differences. J. Nucl. Mater. 2004, 329–333, 166–172. [Google Scholar] [CrossRef]

- Klueh, R.L. Ferritic/martensitic steels for advanced nuclear reactors. Trans. Indian Inst. Met. 2009, 62, 81–87. [Google Scholar] [CrossRef]

- Mansur, L.K. Materials research and development for the spallation neutron source mercury target. J. Nucl. Mater. 2003, 318, 14–25. [Google Scholar] [CrossRef]

- Mansur, L.K.; Gabriel, T.A.; Haines, J.R.; Lousteau, D.C. R&D for the Spallation Neutron Source mercury target. J. Nucl. Mater. 2001, 296, 1–16. [Google Scholar]

- Montanari, R.; Filacchioni, G.; Iacovone, B.; Plini, P.; Riccardi, B. High temperature indentation tests on fusion reactor candidate materials. J. Nucl. Mater. 2007, 367–370, 648–652. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Ghoniem, N.M. Operating temperature windows for fusion reactor structural materials. Fusion Eng. Des. 2000, 51–52, 55–71. [Google Scholar] [CrossRef]

- Van der Schaaf, B.; Gelles, D.S.; Jitsukawak, S.; Kimura, A.; Klueh, R.L.; Moslang, A.; Odette, G.R. Progress and critical issues of reduced activation ferritic/martensitic steel development. J. Nucl. Mater. 2000, 283–287, 52–59. [Google Scholar] [CrossRef]

- Hishinuma, H.; Kohyama, A.; Klueh, R.L.; Gelles, D.S.; Dietz, W.; Ehrlich, K. Current status and future R&D for reduced-activation ferritic/martensitic steels. J. Nucl. Mater. 1998, 258–263, 193–204. [Google Scholar]

- Kittel, J.H.; Frost, B.R.T.; Mustelier, J.P.; Bagley, K.Q.; Crittenden, G.C.; Van Dievoet, J. History of fast reactor fuel development. J. Nucl. Mater. 1993, 204, 1–13. [Google Scholar] [CrossRef]

- Zinkle, S.J. Fusion materials science and technology research opportunities nowand during the ITER era. Fusion Eng. Des. 2014, 89, 1579–1585. [Google Scholar] [CrossRef]

- Zinkle, S.J. Radiation-induced effects on microstructure. In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 1, pp. 65–98. [Google Scholar]

- Kajita, S.; Sakaguchi, W.; Ohno, N.; Yoshida, N.; Saeki, T. Formation process of tungsten nanostructure by the exposure to helium plasma under fusion relevant plasma conditions. Nucl. Fusion 2009, 49, 095005. [Google Scholar] [CrossRef]

- Zenobia, S.; Garrison, L.M.; Kulcinski, G.L. The response of polycrystalline tungsten to 30 keV helium ion implantation at normal incidence and high temperatures. J. Nucl. Mater. 2012, 425, 83–92. [Google Scholar] [CrossRef]

- Tanabe, T. Tritium issues to be solved for establishment of a fusion reactor. Fusion Eng. Des. 2012, 87, 722–777. [Google Scholar] [CrossRef]

- Zinkle, S.J. Fusion materials science: Overview of challenges and recent progress. Phys. Plasmas 2005, 12, 5. [Google Scholar] [CrossRef]

- Dai, Y.; Odette, G.R.; Yamamoto, T. The effects of helium in irradiated structuralalloys. In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 1, pp. 141–193. [Google Scholar]

- Yamamoto, T.; Odette, G.R.; Kishimoto, H.; Rensman, J.-W.; Miao, P. On the effects of irradiation and helium on the yield stress changes and hardening and non-hardening embrittlement of 8Cr tempered martensitic steels: Compilation and analysis of existing data. J. Nucl. Mater. 2006, 356, 27–49. [Google Scholar] [CrossRef]

- Kurtz, R.J.; Alamo, A.; Lucon, E.; Huang, Q.; Jitsukawa, S.; Kimura, A.; Klueh, R.L.; Odette, G.R.; Petersen, C.; Sokolov, M.A.; et al. Recent progress toward development of reduced activation ferritic/martensitic steelsfor fusion structural applications. J. Nucl. Mater. 2009, 386–388, 411–417. [Google Scholar]

- Blanchard, J.P.; Martin, C.J.; Tillack, M.S.; Wang, X.R. Ratcheting Models for Fusion Component Design. Fusion Sci. Technol. 2011, 60, 313–317. [Google Scholar]

- Majumdar, S.; Kalinin, G. ITER structural design criteria and their extension to advanced fusion reactor blankets. J. Nucl. Mater. 2000, 283–287, 1424–1428. [Google Scholar] [CrossRef]

- Bloom, E.E.; Busby, J.T.; Duty, C.E.; Maziasz, P.J.; McGreevy, T.E.; Nelson, B.E.; et al. Critical questions in materials science and engineering for successful development of fusion power. J. Nucl. Mater. 2007, 367–370, 1–10. [Google Scholar] [CrossRef]

- Karditsas, P.J. Design issues and implications for structural integrity of fusion power plant components. Fusion Eng. Des. 2009, 84, 2104–2108. [Google Scholar] [CrossRef]

- Kasahara, N.; Satoh, K.; Tsukimori, K.; Kawasaki, N. Proposals of guidelines for high temperature structural design of fast reactor vessels. In Proccedings of the ASME Pressure Vessels & Piping Conference, New York, NY, USA, 18–22 July 2010.

- Berton, M.N.; Ancelet, O.; Gelineau, O.; Sperandio, M. Presentation of RCC-MRcode 2007 for high temperature reactor and ITER projects: Improvement of the creep fatigue rules. In Proceedings of the ASME Pressure Vessels and Piping Conference, New York, NY, USA, 26–30 July 2009; pp. 567–572.

- Zinkle, S.J.; Möslang, A.; Muroga, T.; Tanigawa, H. Multimodal options for materials research to advance the basis for fusion energy in the ITER era. Nucl. Fusion 2013, 53, 104024. [Google Scholar] [CrossRef]

- Moreau, R.; Brechet, Y.; Maniguet, L. Eurofer corrosion by the flow of the eutectic alloy Pb–Li in the presence of a strong magnetic field. Fusion Eng. Des. 2011, 86, 106–120. [Google Scholar] [CrossRef]

- Zinkle, S.J. Challenges in developing materials for fusion technology—Past, present, and future. Fusion Sci. Technol. 2013, 64, 65–75. [Google Scholar] [CrossRef]

- Ihli, T.; Basu, T.K.; Giancarli, L.M.; Konishi, S.; Malang, S.; Najmabadi, F.; Nishio, S.; Raffray, A.R.; Rao, C.V.S.; Sagara, A.; et al. Review of blanket designs for advanced fusion reactors. Fusion Eng. Des. 2008, 83, 912–919. [Google Scholar] [CrossRef]

- Giancarli, L.; Chuyanov, V.; Abdou, M.A.; Akiba, M.; Hong, B.G.; Laesser, R.; Pan, C.; Strebkov, H.; the TBWG. Breeding blanket modules testing in ITER: An international program on the way to DEMO. Fusion Eng. Des. 2006, 81, 393–405. [Google Scholar] [CrossRef]

- Tillack, M.S.; Turnbull, A.D.; Waganer, L.M.; Malang, S.; Steiner, D.; Sharpe, J.P.; Cadwallader, L.C.; El-Guebaly, L.; Raffray, A.R.; Najmabadi, F.; et al. An evaluation of fusion energy R&D gaps using technology readiness levels. Fusion Sci. Technol. 2009, 56, 949–956. [Google Scholar]

- Stambaugh, R.D.; Chan, V.S.; Garofalo, A.M.; Sawan, M.; Humphreys, D.A.; Lao, L.L.; Leuer, J.A.; Petrie, T.W.; Prater, R.; Snyder, P.B.; et al. Fusion nuclear science facility candidates. Fusion Sci. Technol. 2011, 59, 279–307. [Google Scholar] [CrossRef]

- Burn, J. Fusion Materials Semiannual Progress Report for the Period Ending June 30, 1998; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1998. [Google Scholar]

- Zinkle, S.J.; Eatherly, W.S. Effect of Heat Treatments on the Tensile and Electrical Properties of High-Strength, High-Conductivity Copper Alloys; Fusion Materials Semiannual Progress Report for Period Ending, June 30, 1997, DOE/ER-0313/22; Oak Ridge National Lab: Oak Ridge, TN, USA, 1997. [Google Scholar]

- Harkness, J.C.; Spiegelberg, W.D.; Cribb, W.R. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials, Metals Handbook, 10th ed.; ASM International: Materials Park, OH, USA, 1990; Volume 2, p. 403. [Google Scholar]

- Murray, H.A. Development of a welding procedure for high conductivity, copper-beryllium alloy C17510. In Proceedings of the 14th IEEE/NPSS Symposium on Fusion Engineering, San Diego, CA, USA, 30 Sepember–3 October 1991; Volume 1, pp. 272–275.

- Dieter, G.E. Mechanical Metallurgy, 2nd ed.; McGraw-Hill: New York, NY, USA, 1976. [Google Scholar]

- Haasen, P. Physical Metallurgy; Cambridge Univ. Press: New York, NY, USA, 1978. [Google Scholar]

- Spitznagel, J.A.; Doyle, N.J.; Choyke, W.J.; Greggi, J.G.; McGruer, J.N.; Davis, J.W. Ion irradiation effects on high strength, high conductivity copper alloys. Nucl. Instrum. Meth. B 1986, 16, 279–287. [Google Scholar] [CrossRef]

- Rioja, R.J.; Laughlin, D.E. The sequence of precipitation in Cu-2w/o Be alloys. Acta Metall. 1980, 28, 1301–1313. [Google Scholar] [CrossRef]

- Monzen, R.; Seo, T.; Sakai, T.; Watanabe, C. Precipitation Processes in a Cu–0.9 mass% Be Single Crystal. Mater. Trans. 2006, 47, 2925–2934. [Google Scholar] [CrossRef]

- Xie, G.; Wang, Q.; Mi, X.; Xiong, B.; Peng, L. The precipitation behavior and strengthening of a Cu–2.0 wt% Be alloy. Mater. Sci. Eng. A 2012, 558, 326–330. [Google Scholar]

- Watanabe, C.; Monzen, R. Precipitation process in a Cu-Ni-Be alloy. Diffus. Defect Data B Solid State Phenom. 2011, 172–174, 432–436. [Google Scholar] [CrossRef]

- Fabritsiev, S.; Pokrovsky, A.S.; Zinkle, S.J.; Rowcliffe, A.; Edwards, D.J.; Garner, F.A. The effect of neutron spectrum on the mechanical and physical properties of pure copper and copper alloys. J. Nucl. Mater. 1996, 233–237, 526–533. [Google Scholar] [CrossRef]

- Fabritsiev, S.A.; Pokrovsky, A.S. The effect of neutron irradiation on the electrical resistivity of high-strength copper alloys. J. Nucl. Mater. 1997, 249, 239–249. [Google Scholar] [CrossRef]

- Edwards, D.J. Temperature and Strain Rata Effects in High Strength High Conductivity Copper Alloys Tested in Air; Fusion Materials Semiannual Progress Report for Period Ending, December 31, 1997, DOE/ER-0313/23; Oak Ridge National Lab.: Oak Ridge, TN, USA, 1997; p. 213. [Google Scholar]

- Slattery, K. Personal communication; McDonnell Douglas Corp.: St. Louis, MO, USA, 1997. [Google Scholar]

- Lucas, G.E. Review of small specimen test techniques for irradiation testing. Metall. Trans. A 1990, 21, 1105. [Google Scholar] [CrossRef]

- Sun, Z.; Laitern, C.; Vincent, A. Dynamic embrittlement at intermediate temperature in a Cu–Ni–Si alloy. Mater. Sci. Eng. A 2008, 477, 145–152. [Google Scholar] [CrossRef]

- Laporte, V. Mortensen, Intermediate temperature embrittlement of copper alloys. Int. Mater. Rev. 2009, 54, 94–116. [Google Scholar] [CrossRef]

- Fenici, P.; Boerman, D.J.; Tartaglia, G.P.; Elen, J.D. Effect of fast-neutron irradiation on tensile properties of precipitation-hardened Cu-Cr-Zr alloy. J. Nucl. Mater. 1994, 212–215, 399–403. [Google Scholar] [CrossRef]

- Fabritsiev, S.A.; Pokrovsky, A.S.; Zinkle, S.J.; Edwards, D.J. Low-temperature radiation embrittlement of copper alloys. J. Nucl. Mater. 1996, 233–237, 513–518. [Google Scholar] [CrossRef]

- Fabritsiev, S.A.; Pokrovsky, A.S.; Edwards, D.J.; Zinkle, S.J.; Rowcliffe, A.F. Effect of high-dose neutron irradiation on the mechanical properties and structure of copper alloys and Cu/SS joints for ITER applications. J. Nucl. Mater. 2000, 283–287, 523–527. [Google Scholar] [CrossRef]

- Rowcliffe, A.F.; Mansur, L.K.; Hoelzer, D.T.; Nanstad, R.K. Perspectives on radiation effects in nickel-base alloys for applications in advanced reactors. J. Nucl. Mater. 2009, 392, 341–352. [Google Scholar] [CrossRef]

- Boothby, R.M. Radiation Effects in Nickel-Based Alloys. In Comprehensive Nuclear Materials; Konings, R.J.M., Ed.; Elsevier: Amsterdam, The Netherlands, 2012; Volume 4, pp. 123–150. [Google Scholar]

- Zinkle, S.J. Evaluation of high strength, high conductivity CuNiBe alloys for fusion energy applications. J. Nucl. Mater. 2014, 449, 277–289. [Google Scholar] [CrossRef]

- Barbato, F.; Scarpellini, D.; Malizia, A.; Gaudio, P.; Richetta, P.; Antpnelli, L. X-ray High-Resolution Spectroscopy for Laser-Produced Plasma. Phys. Procedia 2015, 62, 84–91. [Google Scholar] [CrossRef] [Green Version]

- Mattoccia, A.; Bernardone, E.; Digiamberardino, L.; Gaudio, P.; Malizia, A.; Orsini, A. Morphological and structural investigation of (Zn,Al) layered double hydroxides (LDH) nanoplatelets synthesized on aluminum-coated substrates [Studio morfologico di nanostrutture di layered double hydroxides (LDH) depositate su film sottili di alluminio]. Metall. Ital. 2015, 107, 15–22. [Google Scholar]

- Kulite Semiconductor Products, Inc., Leonia, NJ, USA. Available online: www.kulite.com/docs/products/XCE-093.pdf (accessed on 1 March 2016).

- Benedetti, M.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M. T.; Richetta, M. Scaled experiment for Loss of Vacuum Accidents in nuclear fusion devices: Experimental methodology for fluid-dynamics analysis in STARDUST facility. Available online: http://www.wseas.us/e-library/conferences/2011/Corfu/CUTAFLUP/CUTAFLUP-24.pdf (accessed on 19 July 2016).

- Bellecci, C.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M.T.; Quaranta, R. Loss of vacuum accident (LOVA): Comparison of computational fluid dynamics (CFD) flow velocities against experimental data for the model validation. Fusion Eng. Des. 2011, 86, 330–340. [Google Scholar] [CrossRef]

- Bellecci, C.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M.T.; Quaranta, R.; Richetta, M. STARDUST experimental campaign and numerical simulations: Influence of obstacles and temperature on dust resuspension in a vacuum vessel under LOVA. Nucl. Fusion 2011, 51, 053017. [Google Scholar] [CrossRef]

- Gaudio, P.; Malizia, A.; Lupelli, I. Experimental and numerical analysis of dust resuspension for supporting chemical and radiological risk assessment in a nuclear fusion device. In Proceedings of the International Conference on Mathematical Models for Engineering Science (MMES’ 10), Puerto De La Cruz, Spain, 30 November–2 December 2010; pp. 134–147.

- Bellecci, C.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M.T.; Quaranta, R.; Richetta, M. Exerimental Mapping of Velocity Flow Field in Case of L.O.V.A. inside STARDUST facility. In Proceedings of the 37th EPS Conference on Plasma Physics, Dublin, Ireland, 21–25 June 2010; pp. 703–706.

- Bellecci, C.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M.T.; Quaranta, R.; Richetta, M. Characterization of divertor influence in case of LOVA: CFD analysis of STARDUST experimental facility. In Proceedings of the 36th EPS Conference on Plasma Physics, Sofia, Bulgaria, 29 June–3 July 2009.

- Ciparisse, J.-F.; Malizia, A.; Poggi, L.A.; Cenciarelli, O.; Gelfusa, M.; Carestia, M.C.; Di Giovanni, D.; Mancinelli, S.; Palombi, L.; Bellecci, C.; et al. Numerical Simulations as Tool to Predict Chemical and Radiological Hazardous Diffusion in Case of Nonconventional Events. Model. Simul. Eng. 2016, 2016, 1–11. [Google Scholar] [CrossRef]

- Malizia, A.; Carestia, M.; Cafarelli, C.; Milanese, L.; Pagannone, S.; Pappalardo, A.; Pedemonte, M.; Latini, G.; Barlascini, O.; Fiorini, E.; et al. The free license codes as Decision Support System (DSS) for the emergency planning to simulate radioactive releases in case of accidents in the new generation energy plants. WSEAS Trans. Env. Dev. 2014, 10, 453–464. [Google Scholar]

- Camplani, M.; Malizia, A.; Gelfusa, M.; Barbato, F.; Antonelli, L.; Poggi, L.A.; Ciparisse, J.-F.; Salgado, L.; Richetta, M.; Gaudio, P. Image computing techniques to extrapolate data for dust tracking in case of an experimental accident simulation in a nuclear fusion plant. Rev. Sci. Instrum. 2016, 87, 013504. [Google Scholar] [CrossRef] [PubMed]

- Gaudio, P.; Maliza, A.; Camplani, M.; Barbato, F.; Antonelli, L.; Gelfusa, M.; Del Vecchio, M.; Salgado, L.; Bellecci, C.; Richetta, M. Shadowgraph technique applied to STARDUST facility for dust tracking: First results. In Proceedings of 3rd International Conference Frontiers in Diagnostic Technologies (ICFDT3 2013), Rome, Italy, 25–27 November 2013; pp. 97–101.

- Ciparisse, J.-F.; Malizia, A.; Poggi, L.A.; Gelfusa, M.; Murari, A.; Mancini, A.; Gaudio, P. First 3D numerical simulations validated with experimental measurements during a LOVA reproduction inside the new facility STARDUST-Upgrade. Fusion Eng. Des. 2015, 101, 204–208. [Google Scholar] [CrossRef]

- Lupelli, I.; Gaudio, P.; Richetta, M.; Gelfusa, M.; Malizia, A.; Belluzzo, I.; Richetta, M. Numerical study of air jet flow field during a loss of vacuum. Fusion Eng. Des. 2014, 89, 2048–2052. [Google Scholar] [CrossRef]

- Benedetti, M.; Gaudio, P.; Lupelli, I.; Malizia, A.; Porfiri, M.T.; Richetta, M. Large Eddy simulation of loss of Vacuum accident in STARDUST facility. Fusion Eng. Des. 2013, 88, 2665–2668. [Google Scholar] [CrossRef]

- Malizia, A.; Gelfusa, M.; Francia, G.; Boccitto, M.; Del Vecchio, M.; Di Giovanni, D.; Richetta, M.; Bellecci, C.; Gaudio, P. Design of a new experimental facility to reproduce LOVA and LOCA consequences on dust resuspension. Fusion Eng. Des. 2015, 98–99, 2191–2195. [Google Scholar] [CrossRef]

| Alloy (wt.%) | Oxidation Test Results |

|---|---|

| W-Cr14-Ti2 | Slow oxidation |

| W-Cr18-Ti2 | Slow oxidation |

| W-Cr16-Zr9 | Film delamination |

| W-Hf17-Ta15 | Film delamination |

| W-Hf32-Ti2 | Film delamination |

| W-Ta12-Ti2 | Film delamination |

| W-Ta12-Zr5 | Fast oxidation |

| W-Zr2-Ti1 | Film delamination |

| W-Y7-Cr3 | Relatively slow oxidation |

| W-Y24-Cr2 | Film delamination |

| Material | Oxidation behavior | Thermal Conductivity | DBTT |

|---|---|---|---|

| W-Cr10-Si10 | Lower at 600 °C Higher at 1000 °C In comparison with thin films that have the same composition | 16 W/m K at 500 °C | 1000–1050 °C |

| W-Cr12-Ti2.5 | Same at 600 °C Higher at 800 & 1000 °C In comparison with thin films that have the same composition | 50 W/m K at 500–600 °C | 900 °C |

| Parameter | Fusion | Fission (Generation IV) | Spallation |

|---|---|---|---|

| Working fluid | H2O, He, Li, PbLi, FLiBe | H2O (SC), He, Na, Pb, PbBi | Hg, PbBi, H2O |

| Energy | <14,1 MeV | <1–2 MeV (most n) | ≤1 GeV (p and n) |

| He/dpa * | 10 | 0,1–50 | 50–100 |

| Stresses | Moderate, slow varying ** | Moderate, slow varying | High pulsed |

| System (Working Fluid) | Component | T °C | Max dose, dpa | Maximum He, ppm | Candidate Alloys |

|---|---|---|---|---|---|

| SNS a (mercury) | Spallation target module | 80–150 | 5 | 200 | 316LN |

| ITER (water) | First wall/Blanket | 100–300 | 3 | 75 | 316LN |

| SCWR b | Fuel assembly | 280–620 | 15 | 200 | Advanced low swelling steels: D9, PN316, HT-UPS |

| SC c (water) | Core support/internals | 280–500 | 0,1–20 | 250 |

| System (working fluid) | Component | T °C | Max dose, dpa | Maximum He, ppm | Candidate Alloys |

|---|---|---|---|---|---|

| SSTR a (water) | First wall/blanket | 300–550 | 100 | >1000 | Low activation 8%–9%Cr ferritic-martensitic steels |

| HCLL b (He) | First wall/blanket | 270–550 | 100 | >1000 | |

| HPBC c (He) | First wall/blanket | 300–550 | 100 | >1000 | |

| SCWR (SC water) | Fuel assembly | 280–620 | 15 | 20 | Advanced 8%–12% ferritic-martensitic steels |

| Core support/internals | 280–500 | 0,1–20 | 20 | ||

| FR d (Pb-Bi, Pb) | Fuel assembly | 300–550 | 150 | 15 |

| Data from | Mach Number Peak |

|---|---|

| Numerical simulation | 0.55 |

| Experimental campaign | 0.4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Malizia, A.; Poggi, L.A.; Ciparisse, J.-F.; Rossi, R.; Bellecci, C.; Gaudio, P. A Review of Dangerous Dust in Fusion Reactors: from Its Creation to Its Resuspension in Case of LOCA and LOVA. Energies 2016, 9, 578. https://doi.org/10.3390/en9080578

Malizia A, Poggi LA, Ciparisse J-F, Rossi R, Bellecci C, Gaudio P. A Review of Dangerous Dust in Fusion Reactors: from Its Creation to Its Resuspension in Case of LOCA and LOVA. Energies. 2016; 9(8):578. https://doi.org/10.3390/en9080578

Chicago/Turabian StyleMalizia, Andrea, Luigi Antonio Poggi, Jean-François Ciparisse, Riccardo Rossi, Carlo Bellecci, and Pasquale Gaudio. 2016. "A Review of Dangerous Dust in Fusion Reactors: from Its Creation to Its Resuspension in Case of LOCA and LOVA" Energies 9, no. 8: 578. https://doi.org/10.3390/en9080578