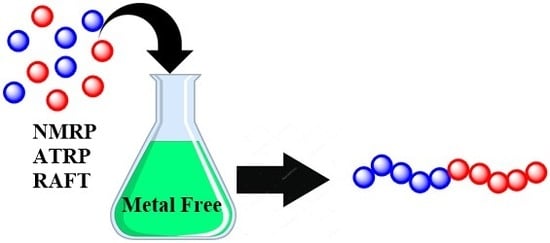

Metal Free Reversible-Deactivation Radical Polymerizations: Advances, Challenges, and Opportunities

Abstract

:1. Introduction

2. Nitroxide Mediated Radical Polymerization (NMRP)

2.1. Reaction Mechanism of NMRP

2.2. Development of Nitroxides for NMRP

2.3. Application of NMRP in Materials Synthesis

3. Atom Transfer Radical Polymerization (ATRP)

3.1. Mechanism in ATRP

3.2. Recent Developments in ATRP

3.3. ATRP in Materials Synthesis

4. Reversible Addition Fragmentation Chain Transfer Radical Polymerization (RAFT)

4.1. Mechanism of RAFT Polymerization

4.2. Recent Developments in RAFT

4.3. RAFT in Materials Synthesis

5. Conclusions and Outlook

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| 4CzIPN | 2,4,5,6-tetra(9H-carbazol-9-yl) isophthalonitril |

| 4VBC | 9-(4-vinyl-benzyl)-9H-carbazole |

| Ac | Acrylate |

| AAm | Acrylamide |

| AcAc | Acetylacetone |

| AIBN | 2,2′-azobis(2-methylpropionitril) |

| AN | Acrylonitrile |

| ARGET ATRP | Activator Regenerated by Electron Transfer ATRP |

| ATRP | Atom Transfer Radical Polymerization |

| BA | Butyl acrylate |

| tBA | t-butyl acrylate |

| BAI | Bis-(alkylphenyl)iodonium hexafluorophosphate |

| BMI | N-benzylmaleimide |

| BP | Benzophenon |

| BPO | Benzoylperoxide |

| tBS | t-butylstyrene |

| BSA | Bovine Serum A |

| BzMA | Benzyl methacrylate |

| CA | Cyanoacrylate |

| CMI | N-cyclohexylmaleimide |

| CPADB | Cyanopentanoic acid dithiobenzoate |

| CP–I | 2-cyanopropyl iodide |

| CQ | Camphorquinone |

| CTA | Chain Transfer Agent |

| CTS | Chitosan |

| Dispersity | |

| DAEMA | Dehydroabietic ethyl methacrylate |

| DBN | Di-t-butyl nitroxide |

| DC | Dissociation-Combination |

| DCF | Dead Chain Fraction |

| DDMAT | S-dodecyl-S′-(α,α′-dimethyl-α′′-acetic acid) trithiocarbonate |

| DET | Dissociative Electron Transfer |

| DET-RAFT | Dissociative Electron Transfer RAFT |

| DFT | Density Functional Theory |

| DMA | N,N-dimethylacetamide |

| DMAEMA | 2-(dimethylamino)ethyl methacrylate |

| DMEDA | N,N-dimethylethylenediamine |

| DMPA | 2,2-dimethoxy-2-phenylacetophenone |

| DPAIO | 2,2-diphenyl-3-phenylimino-2,3-dihydroindol-1-yloxyl |

| DT | Degenerative Exchange Chain Transfer |

| e-ATRP | Electro ATRP |

| EDA | Ethylenediamine |

| ESR | Electron Spin Resonance |

| FMA | Furfuryl methacrylate |

| GOx | Glucose Oxidase |

| HEA | 2-hydroxyethyl acrylate |

| HEMA | 2-hydroxyethyl methacrylate |

| HRP | Horseraddish Peroxidase |

| I | Isoprene |

| ICAR ATRP | Initiators for Continuous Activator Regeneration ATRP |

| IRT | Intermediate Radical Termination |

| IRTO | Intermediate Radical Termination with Oligomers |

| ISET | Inner Sphere Electron Transfer |

| ITX | Isopropyl thioxanthone |

| LAM | Less Activated Monomers |

| MA | Methacrylate |

| MAEMI | 2-(dimethylamine)ethyl methacrylate |

| MAM | More Activated Monomers |

| Me-PTH | 10-methyl phenothiazine |

| MMA | Methyl methacrylate |

| MTEMPO | 4-methoxy TEMPO |

| Mtn | Transition Metal |

| MWD | Molecular Weight Distribution |

| NBS | N-bromosuccinimide |

| NHS | N-hydroxysuccinimide |

| NMMA | Methyl-2-methyl-3-nitro-2-nitrosopropionate |

| NMRP | Nitroxide Mediated Radical Polymerization |

| NNDMAA | N,N-dimethylacrylamide |

| NPI | Maleimide-N-phenylmaleimide |

| MMA | N-vinylcaprolactam |

| NVI | N-vinylimidazole |

| NVP | N-vinylpyrrolidone |

| OSET | Outer Sphere Electron Transfer |

| OSET-C | Continuous Outer Sphere Electron Transfer |

| OSET-SW | Stepwise Outer Sphere Electron Transfer |

| PDEAEMA | poly(N,N-diethylaminoethyl methacrylate) |

| PEG | Poly(ethylene glycol) |

| PEGA | Poly(ethylene glycol) methyl ether acrylate |

| PEGMA | Poly(ethylene glycol) methyl ether methacrylate |

| PEO | Poly(ethylene oxide) |

| PET-ATRP | Photo-induced Electron Transfer ATRP |

| PET-RAFT | Photo-induced Electron Transfer RAFT |

| Ph-PTH | 10-phenyl phenothiazine |

| PMDC | Morpholine-4-dithiocarbamate |

| PMDETA | N,N,N′,N″,N″-pentamethyldiethylenetriamine |

| PNIPAm | Poly(N-isopropylacrylamide) |

| PRE | Persistent Radical Effect |

| PTH | Phenothiazine |

| RAFT | Reversible Addition Fragmentation Chain Transfer Polymerization |

| RCMP | Reversible Complexation Mediated Polymerization |

| RCT | Reversible Chain Transfer |

| RCTP | Reversible Chain Transfer Polymerization |

| RDRP | Reversible-Deactivation Radical Polymerization |

| ROMP | Ring-Opening Metathesis Polymerization |

| SARA-ATRP | Supplementary Activator and Reducing Agent ATRP |

| SBMA | Soybean oil methacrylate |

| SET-LRP | Single Electron Transfer Living Radical Polymerization |

| SET-RAFT | Single Electron Transfer RAFT |

| SG1 | N-t-butyl-1-diethoxyphosphoryl-N-oxidanyl-2,2-dimethylpropan-1-amine |

| SS | Styrene sulfonate |

| St | Styrene |

| SUMI | Single Unit Monomer Insertion |

| TBA | Tributylamine |

| TDAE | Tetrakis (dimethylamino) ethylene |

| TEA | Triethylamine |

| TEDIO | 1,1,3,3,-tetraethylisoindolin-2-oxyl |

| TEMPO | 2,2,6,6,-tetramethyl-2-piperidin-1-oxyl |

| TIPNO | 2,2,5-trimethyl-4-phenyl-3-azahexane-3-nitroxide |

| TMEDA | Tetramethylethylenediamine |

| TPO | 2,4,6-trimethylbenzoyl-diphenylphosphine oxide |

| TX | Thioxanthone |

| V70 | 2,2′-azobis(4-methoxy-2,4-dimethyl valeronitrile) |

| Vac | Vinyl acetate |

References

- Szwarc, M. “Living” Polymers. Nature 1956, 176, 1168–1169. [Google Scholar] [CrossRef]

- Szwarc, M.; Levy, M.; Milkovich, R. Polymerization Initiated by Electron Transfer Monomer. A New Method of Formation of Block Copolymers. J. Am. Chem. Soc. 1956, 78, 2656–2657. [Google Scholar] [CrossRef]

- Pan, X.; Tasdelen, M.A.; Laun, J.; Junkers, T.; Yagci, Y.; Matyjaszewski, K. Photomediated controlled radical polymerization. Prog. Polym. Sci. 2016, 62, 73–125. [Google Scholar] [CrossRef]

- Tasdelen, M.A.; Kahveci, M.U.; Yagci, Y. Telechelic polymers by living and controlled/living polymerization methods. Prog. Polym. Sci. 2011, 36, 455–567. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E. The History of Nitroxide-mediated Polymerization. In Nitroxide Mediated Polymerization: From Fundamentals to Applications in Materials Science, 19th ed.; Gigmes, D., Ed.; RSC Polymer Series; RSC: London, UK, 2016; Volume 19, pp. 1–44. [Google Scholar]

- Jansen, G. Spin Trapping. Acc. Chem. Res. 1971, 4, 31–40. [Google Scholar] [CrossRef]

- Chalfont, G.R.; Perkins, M.J.; Horsfield, A. Probe for homolytic reactions in solution. II. Polymerization of styrene. J. Am. Chem. Soc. 1968, 90, 7141–7142. [Google Scholar] [CrossRef]

- Kunitake, T.; Murakami, S. Study of Radical Polymerizations by Spin Trapping I. Trapping of Initiating and Propagating Radicals. Polym. J. 1972, 3, 249–251. [Google Scholar] [CrossRef]

- Kunitake, T.; Murakami, S. An application of spin trapping to radical polymerization. J. Polym. Sci. Chem. Ed. 1974, 12, 67–81. [Google Scholar] [CrossRef]

- Sato, T.; Otsu, T. Evaluation of relativities of vinyl monomers towards t-butoxy radical by means of spin trapping technique. Polymer 1975, 16, 389–391. [Google Scholar] [CrossRef]

- Sato, T.; Otsu, T. Application of spin trapping technique to radical polymerization, 14. Initiation reaction of vinyl monomers with tert-butoxyl radical and evaluation of monomer reactivities. Macromol. Chem. 1977, 178, 1941–1950. [Google Scholar] [CrossRef]

- Roszantsev, E.G.; Sholle, V.D. Synthesis and Reactions of Stable Nitroxyl Radicals II. Reactions. Synthesis 1971, 8, 401–414. [Google Scholar] [CrossRef]

- Berdnarek, D.; Moad, G.; Rizzardo, E.; Solomon, D.H. End groups of poly(methyl methacrylate-co-styrene) prepared with tert-butoxy, methyl, and/or phenyl radical initiation: Effects on solvent, monomer composition, and conversion. Macromolecules 1988, 21, 1522–1528. [Google Scholar] [CrossRef]

- Bizilj, S.; Kelly, D.; Serelis, A.; Solomon, D.; White, K. The Self-Reactions of 1-Methoxycarbonyl-1-Methylethyl and Higher Ester Radicals: Combination vs. Disproportionation and Oligomeric Products from Secondary Reactions. Aust. J. Chem. 1985, 38, 1657–1673. [Google Scholar] [CrossRef]

- Cutberthson, M.J.; Rizzardo, E.; Solomon, D.H. The reactions of t-butoxyl with unsaturated hydrocarbons: Structure and reactivity of allylic radicals. Aust. J. Chem. 1983, 36, 1957–1973. [Google Scholar] [CrossRef]

- Rizzardo, E.; Serelis, A.K.; Solomon, D.H. Initiation mechanisms in radical polymerizations: Reaction of cumyloxy radicals with methyl methacrylate and styrene. Aust. J. Chem. 1982, 35, 2013–2024. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E.; Solomon, D.H. The Reaction of Benzoyloxy Radicals with Styrene-Implications Concerning the Structure of Polystyrene. J. Macromol. Sci. 1982, A17, 51–59. [Google Scholar] [CrossRef]

- Rizzardo, E.; Solomon, D.H. On the Origins of Nitroxide Mediated Polymerization (NMP) and Reversible Addition-Fragmentation Chain Transfer (RAFT). Aust. J. Chem. 2012, 65, 945–969. [Google Scholar] [CrossRef]

- Solomon, D.H.; Rizzardo, E.; Cacioli, P. Polymerization Processes and Polymers Produced Thereby. U.S. Patent 4,581,429, 8 April 1986. [Google Scholar]

- Georges, M.K.; Veregin, R.P.N.; Kazmaier, P.M.; Harmer, G.K. Narrow molecular weight resins by a free-radical polymerization process. Macromolecules 1993, 26, 2987–2988. [Google Scholar] [CrossRef]

- Hawker, C.J.; Barklay, G.C.; Orellana, A.; Dao, J.; Devonport, W. Initiating systems for Nitroxide-Mediated “Living” Free Radical Polymerization: Synthesis and Evaluation. Macromolecules 1996, 29, 5245–5254. [Google Scholar] [CrossRef]

- Hawker, C.J. Molecular Weight Control by a “Living” Free-Radical Polymerization Process. J. Am. Chem. Soc. 1994, 116, 11185–11186. [Google Scholar] [CrossRef]

- Hawker, C.J.; Bosman, A.W.; Harth, E. New Polymer Synthesis by Nitroxide Mediated Living Radical Polymerization. Chem. Rev. 2001, 101, 3661–3688. [Google Scholar] [CrossRef] [PubMed]

- Hawker, C.J. “Living” Free Radical Polymerization: A Unique Technique for the Preparation of COntrolled Macromolecular Architectures. Acc. Chem. Res. 1997, 30, 373–382. [Google Scholar] [CrossRef]

- Hawker, C.J.; Barklay, G.C.; Dao, J.L. Radical Crossover in Nitroxide Mediated “Living” Free Radical Polymerization. J. Am. Chem. Soc. 1996, 118, 11467–11471. [Google Scholar] [CrossRef]

- Yoshida, E. Photo-living radical polymerization of methyl methacrylate by a nitroxide mediator. Colloid Polym. Sci. 2008, 286, 1663–1666. [Google Scholar] [CrossRef]

- Yoshida, E. Nitroxide-mediated photo-living radical polymerization of vinyl acetate. Colloid Polym. Sci. 2010, 288, 73–78. [Google Scholar] [CrossRef]

- Benoit, D.; Chaplinski, V.; Braslau, R.; Hawker, C.J. Development of a Universal Alkoxyamine for “Living” Free Radical Polymerization. J. Am. Chem. Soc. 1999, 121, 3904–3920. [Google Scholar] [CrossRef]

- Grimaldi, S.; Finet, J.-P.; Moigne, F.L.; Zheghdaoui, A.; Tordo, P.; Benoit, D.; Fontanille, M.; Gnanou, Y. Acyclic β-Phosphonylated Nitroxides: A New Series of Counter-Radicals for “Living”/Controlled Free Radical Polymerization. Macromolecules 2000, 33, 1141–1147. [Google Scholar] [CrossRef]

- Sciannamea, V.; Jerome, R.; Detrembleur, C. In-Situ Nitroxide-Mediated Radical Polymerization (NMP) Processes: Their Understanding and Optimization. Chem. Rev. 2008, 108, 1104–1126. [Google Scholar] [CrossRef] [PubMed]

- Green, A.C.; Grubs, R.B. Current Methods for N-Alkoxyamine Synthesis. In Controlled/Living Radical Polymerization: Progress in RAFT, DT, NMP & OMRP; Matyjaszewski, K., Ed.; ACS: Washington, DC, USA, 2009; Chapter 6; pp. 81–93. [Google Scholar]

- Georges, M.K.; Veregin, R.P.N.; Katzmaier, P.M.; Hamer, G.K.; Saban, M. Narrow Polydispersity Polystyrene by a Free-Radical Polymerization Process-Rate Enhancement. Macromolecules 1994, 27, 7228–7229. [Google Scholar] [CrossRef]

- Veregin, R.P.N.; Odell, P.G.; Michalka, L.M.; Georges, M.K. Mechanism of Rate Enhancement Using Organic Acids in Nitroxide-Mediated Living Free-Radical Polymerization. Macromolecules 1996, 29, 4161–4163. [Google Scholar] [CrossRef]

- Baldovi, M.V.; Mohtat, N.; Scaiano, J.C. Influence of Acids on Reaction Rates of Free Radical Scavanging by TEMPO. Relevance to “Living” Free Radical Polymerization. Macromolecules 1996, 29, 5497–5499. [Google Scholar] [CrossRef]

- Odell, P.G.; Veregin, R.P.N.; Michalka, L.M.; Georges, M.K. Characteristics of the Stable Free Radical Polymerization of Styrene in the Presence of 2-Fluoro-1-methylpyridinium p-Toluenesulfonate. Macromolecules 1997, 30, 2232–2237. [Google Scholar] [CrossRef]

- Keoshkerian, B.; Georges, M.; Quinlan, M.; Veregin, R.; Goodbrand, B. Polyacrylates and Polydienes to High Conversion by a Stable Free Radical Polymerization Process: Use of Reducing Agents. Macromolecules 1998, 31, 7559–7561. [Google Scholar] [CrossRef]

- Malmstroem, E.E.; Miller, R.D.; Hawker, C.J. Development of a new class of rate-accelerating additives for nitroxide-mediated ‘living’ free radical polymerization. Tetrahedron 1997, 53, 15225–15236. [Google Scholar] [CrossRef]

- Greszta, D.; Matyjaszewski, K. TEMPO-mediated polymerization of styrene: Rate enhancement with dicumyl peroxide. J. Polym. Sci. A Polym. Chem. 1997, 35, 1857–1861. [Google Scholar] [CrossRef]

- Ohno, K.; Tsujii, Y.; Fukuda, T. Mechanism and Kinetics of Nitroxide-Controlled Free Radical Polymerization. Thermal Decomposition of 2,2,6,6,-Tetramethyl-1-polystyroxypiperidines. Macromolecules 1997, 30, 2503–2506. [Google Scholar] [CrossRef]

- Baethge, H.; Butz, S.; Schmidt-Naake, G. Rate enhancement of the N-oxyl-controlled free radical copolymerization of styrene with N-vinylcarbazole. Angew. Makromol. Chem. 1999, 267, 52–56. [Google Scholar] [CrossRef]

- Gerard, P.; Couvreur, L.; Magnet, S.; Ness, J.; Schmidt, S. Controlled Architecture Polymers at Arkema: Synthesis, Morphology and Properties of All-Acyrylic Block Copolymers. In Controlled/Living Radical Polymerization: Progress in RAFT, DT, NMP & OMRP; Matyjaszewski, K., Ed.; ACS: Washington, DC, USA, 2009; Chapter 24; pp. 361–376. [Google Scholar]

- Lessard, B.; Tervno, C.; Maric, M. High-Molecular-Weight Poly(tert-butyl acrylate) by Nitroxide-Mediated Polymerization: Effect of Chain Transfer to Solvent. Macromol. React. Eng. 2009, 3, 245–256. [Google Scholar] [CrossRef]

- Sundararman, A.; Stephan, T.; Grubbs, R.B. Reversible Restructuring of Aqueous Block Copolymer Assemblies through Stimulus-induced Changes in Amphiphilicity. J. Am. Chem. Soc. 2008, 130, 12264–12265. [Google Scholar] [CrossRef] [PubMed]

- Junkers, T.; Wong, E.H.H.; Stenzel, M.H.; Barner-Kowollik, C. Formation Efficiency of ABA Blockcopolymers via Enhanced Spin Capturing Polymerization (ESCP): Locating the Alkoxyamine Function. Macromolecules 2009, 42, 5027–5035. [Google Scholar] [CrossRef]

- Theato, P.; Killinger, D. Synthesis of Photoreactive Block Copolymer Based on 1-Iminopyridinium Ylides. Aust. J. Chem. 2010, 63, 1164–1168. [Google Scholar] [CrossRef]

- Gamsy, C.G.; Beyou, E.; Bourgeat-Lami, E. Micellar behaviour of well-defined polystyrene-based block copolymers with triethoxysilyl reactive groups and their hydrolysis-condensation. J. Polym. Sci. A Polym. Chem. 2010, 48, 784–793. [Google Scholar] [CrossRef]

- Zhang, W.; Yan, Y.; Zhou, N.; Cheng, Z.; Zhou, J.; Xia, C.; Zhu, X. Controlled synthesis and fluorescence properties of poly(9-(4-vinylbenzyl)-9H-carbazole) via nitroxide-mediated living free-radical polymerization. Eur. Polym. J. 2008, 44, 3300–3305. [Google Scholar] [CrossRef]

- Quinn, J.D.; Register, R.A. Nitroxide-mediated radical polymerization of N-ethyl-2-vinylcarbazole. Polym. Adv. Technol. 2008, 19, 556–559. [Google Scholar] [CrossRef]

- Tsuchiya, K.; Sakaguchi, K.; Kawakami, A.; Taka, H.; Kita, H.; Shimomura, T.; Ogino, K. Charge transporting block copolymer for morphology control in light emitting device based on polymer blends. Synth. Mat. 2010, 160, 1679–1982. [Google Scholar] [CrossRef]

- Pan, T.N.T.; Bertin, D. Synthesis of Water-Soluable Homopolymers and Block Copolymers in Homogeneous Aqueous Solution via Nitroxide-Mediated polymerization. Macromolecules 2008, 41, 1886–1895. [Google Scholar]

- Enright, T.E.; Cunningham, M.F.; Keoshkerian, B. Nitroxide-Mediated Bulk and Miniemulsion Polymerization in a Continuous Tubular Reactor: Synthesis of Homo-, Di- and Triblock Copolymers. Macromol. React. Eng. 2010, 4, 186–196. [Google Scholar] [CrossRef]

- Ramirez-Wong, D.G.; Posada-Valez, C.A.; Saldivar-Guerra, E.; Luna-Barcenas, J.G.; Ott, C.; Schubert, U.S. Silicon-based and fluorinated polymeric surfactants for nitroxide mediated dispersion polymerization in supercritical carbon dioxide. Macromol. Symp. 2009, 283–284, 120–129. [Google Scholar] [CrossRef]

- Yang, J.; Zhang, Z.; Men, X.; Xu, X.; Zhu, X. Reversible conversion of water-droplet mobility from rollable to pinned on a superhydrophobic functionalized carbon nanotube film. J. Colloid Interface Sci. 2010, 346, 241–247. [Google Scholar] [CrossRef] [PubMed]

- Guillet, P.; Fustin, C.-A.; Mugemana, C.; Ott, C.; Schubert, U.S.; Gohy, J.-F. Tuning block copolymer micelles by metal-ligand interactions. Soft Matter 2008, 4, 2278–2282. [Google Scholar] [CrossRef]

- Datsuyuk, V.; Billon, L.; Guerret-Piecourt, C.; Dagreou, S.; Passade-Boupatt, N.; Bourrigaud, S.; Guerret, O.; Couvreur, L. In situ nitroxide-mediated polymerized poly(acrylic acid) as a stabilizer/compatibilizer carbon nanotube/polymer composites. J. Nanomater. 2007, 2007, 74769. [Google Scholar] [CrossRef]

- Fleischmann, S.; Komber, H.; Voit, B. Diblock Copolymer as Scaffold for Efficient Functionalization via Click Chemistry. Macromolecules 2008, 41, 5255–5264. [Google Scholar] [CrossRef]

- Maeda, R.; Hayakawa, T.; Tokita, M.; Kakimoto, M.-A.; Urushibata, H. Double Ordered Layers within Microphase-Stucture of Double Liquid Crystalline Side-chain Type Block Copolymer. Chem. Lett. 2008, 37, 1174–1175. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E. Alkoxyamine-Initiated Living Radical Polymerization: Factors Affecting Alkoxyamine Homolysis Rate. Macromolecules 1995, 28, 8722–8728. [Google Scholar] [CrossRef]

- Puts, R.D.; Sogah, D.Y. Control of Living Free-Radical Polymerization by a New Chiral Nitroxide and Implcation for the Polymerization Mechanism. Macromolecules 1996, 29, 3323–3325. [Google Scholar] [CrossRef]

- Veregin, R.P.N.; Georges, M.K.; Hamer, G.K.; Kazmaier, P.M. Mechanism of Living Free Radical Polymerization with Narrow Polydispasity: Electro Spin Resonance and Kinetic Studies. Macromolecules 1995, 28, 4391–4398. [Google Scholar] [CrossRef]

- Grimaldi, S.; Finet, J.P.; Zeghadaoui, A.; Tordo, P.; Benoit, D.; Gnanou, Y.; Fontaille, M.; Nicol, P.; Piersond, J.F. Synthesis and Application to “Living” Free Radical Polymerization of a New Class of Nitroxyl Radicals. ACS Dev. Polym. Chem. 1997, 38, 651–652. [Google Scholar]

- Benoit, D.; Grimaldi, S.; Robin, S.; Finet, J.-P.; Tordo, P.; Gnanou, Y. Kinetics and Mechanism of Controlled Free-Radical Polymerization of Styrene and n-Butyl Acrylate in the Presence of an Acyclic β-Phosphonylated Nitroxide. J. Am. Chem. Soc. 2000, 122, 5929–5939. [Google Scholar] [CrossRef]

- Listigovers, N.A.; Georges, M.K.; Odell, P.G.; Keoshkerian, B. Narrow Polydispersity Diblock and Triblock Copolymers of Alkyl Acrylates by a “Living” Stable Free Radical Polymerization. Macomolecules 1996, 29, 8992–8993. [Google Scholar] [CrossRef]

- Ciriano, M.V.; Korth, H.G.; Scheppinger, W.B.V.; Mulder, P. Thermal stability of 2,2,6,6,-Tetramethylpipiridine-1-oxyl (TEMPO) and Related N-Alkoxyamines. J. Am. Chem. Soc. 1999, 121, 6375–6381. [Google Scholar] [CrossRef]

- Skene, W.G.; Belt, S.T.; Connoly, T.J.; Hahn, P.; Scaiano, J.C. Decomposition Kinetics, Arrhenius Parameters, and Bond Dissociation Energies for Alkoxyamines of Relevance in “Living” Free Radical Polymerization. Macromolecules 1998, 31, 9103–9105. [Google Scholar] [CrossRef]

- Bon, S.A.F.; Chambard, G.; German, A.L. Nitroxide-Mediated Living Polymerization: Determination of the Rate Coefficient for Alkoxyamine C-O Bond Homolysis by Quantitative ESR. Macromolecules 1999, 32, 8269–8276. [Google Scholar] [CrossRef]

- Kothe, T.; Marque, S.; Martscheke, R.; Popov, M.; Fischer, H. Radical reaction kinetics during homolysis of N-alkoxyamines: Verification of the persistent radical effect. J. Chem. Soc. Perkin Trans. 1998, 2, 1553–1560. [Google Scholar] [CrossRef]

- Engel, P.S.; Duan, S.; Arhancet, G.B. Thermolysis of a Tertiary Alkoxyamine. Recombination and Disproportionation of α-Phenylethyl/Diethyl Nitroxyl Radical Pairs. J. Org. Chem. 1997, 62, 3537–3541. [Google Scholar] [CrossRef]

- Li, I.; Howell, B.A.; Matyjaszewski, K.; Shigemoto, T.; Smith, P.B.; Priddy, D.B. Kinetics and decomposition of 2,2,6,6,-tetramethyl-1-(1-phenylethoxy)piperidine and its implication on nitroxyl-mediated styrene polymerization. Macromolecules 1995, 28, 6692–6693. [Google Scholar] [CrossRef]

- Grattan, D.W.; Carlson, D.J.; Howard, J.A.; Wiles, D.M. The thermal decomposition of 1-(2′-cyano-2′-propoxy)-4-oxo-2,2,6,6,-tetramethylpiperidine. Can. J. Chem. 1979, 57, 2834–2842. [Google Scholar] [CrossRef]

- Mercier, C.L.; Gaudel, A.; Siri, D.; Tordo, P.; Marque, S.; Martschke, R.; Fischer, H. Characteristics of phosphonylated nitroxides and alkoxyamines used in controlled/”living” radical polymerization. Polym. Prepr. Am. Chem. Soc. Div. Polym. Chem. 1999, 313–314. [Google Scholar]

- Katzmaier, P.M.; Moffat, K.A.; Georges, M.K.; Veregin, R.P.N.; Hamer, G.K. Free-Radical Polymerization for Narrow-Polydispersity Resins. Semiempirical Molecular Orbital Calculations as a Criterion for Selecting Stable Free Radical Reversible Terminators. Macromolecules 1995, 28, 1841–1846. [Google Scholar] [CrossRef]

- Marque, S.R.A.; Mercier, C.L.; Tordo, P.; Fischer, H. Factors Influenceing the C-O-Bond Homolysis of Trialkylhydroxylamines. Macromolecules 2000, 33, 4403–4410. [Google Scholar] [CrossRef]

- Mercier, C.L.; Acerbis, S.; Bertin, D.; Chauvin, F.; Gigmes, D.; Guerret, O.; Lansalot, M.; Marque, S.; Moigne, F.L.; Fischer, H.; Tordo, P. Design and use of β-phosphorus nitroxides and alkoxyamines in controlled/”living” free radical polymerization. Macromol. Symp. 2002, 182, 225–247. [Google Scholar] [CrossRef]

- Braslau, R.; Naik, N.; Zipse, H. Stereoselective Coupling of Prochiral Radicals with a Chrial C2-Symmetric Nitroxide. J. Am. Chem. Soc. 2000, 122, 8421–8434. [Google Scholar] [CrossRef]

- Cuatepotoz-Diaz, R.; Albores-Valesco, M.; Saldivar-Guerra, E.; Jimenez, F.B. Nitroxide mediated polymerization using diphenyl azabutane N-oxides. A study of electron effects and of the [nitroxide]/[initiator] ratio on the polymerization control. Polymer 2004, 45, 815–824. [Google Scholar] [CrossRef]

- Gaudel-Siri, A.; Siri, D.; Tordo, P. Homolysis of N-alkoxyamine: A Computational Study. Chem. Phys. Chem. 2006, 7, 430–438. [Google Scholar] [CrossRef] [PubMed]

- Miura, Y.; Nakamura, N.; Taniguchi, J. Low-Temperature “Living” Radical Polymerization of Styrene in the Presence of Nitroxides with Spiro Structures. Macromolecules 2001, 34, 447–455. [Google Scholar] [CrossRef]

- Miura, Y.; Nakamura, N.; Taniguchi, J. Radical polymerization of butyl acrylate and random copolymerization of styrene and butyl acrylate and styrene and methyl methacrylate mediated by monospiro- and dispiropiperidinyl-N-oxyl radicals. Polymer 2003, 44, 3461–3467. [Google Scholar] [CrossRef]

- Jing, Y.; Mardyukov, A.; Bergander, K.; Daniliuc, C.G.; Struder, A. Synthesis of Bulky Nitroxides, Characteriyation, and Their Application in Controlled Radical Polymerization. Macromolecules 2014, 47, 3595–3602. [Google Scholar] [CrossRef]

- Jing, Y.; Tesch, M.; Wang, L.; Daniliuc, C.G.; Struder, A. Synthesis of bulky nitroxides and its application in the nitroxide-mediated radical polymerization. Tetrahedron 2016, 72, 7665–7671. [Google Scholar] [CrossRef]

- Siegenthaler, K.O.; Studer, A. Nitroxide-Mediated Radical Polymerization—Increase of Steric Demand in Nitroxides. How Much is Too Much? Macromolecules 2006, 39, 1347–1352. [Google Scholar] [CrossRef]

- Hodgson, J.L.; Roskop, L.B.; Gordon, M.S.; Lin, C.Y.; Coote, L. Side Reaactions of Nitroxide-Mediated Polymerization: N- versus O-C Cleavage of Alkoxyamines. J. Phys. Chem. A 2010, 114, 10458–10466. [Google Scholar] [CrossRef] [PubMed]

- Blachon, A.; Marque, S.R.A.; Roubaud, V.; Siri, D. Diastereomer Effect on the Homolysis of the C-ON Bond in Alkoxyamines: A DFT investigation of 1,3-Diphenylbutyl-TEMPO. Polymers 2010, 2, 353–363. [Google Scholar] [CrossRef]

- Cunningham, M.F. Recent progress in nitroxide-mediated polymerization in miniemulsion. C. R. Chim. 2003, 6, 1351–1374. [Google Scholar] [CrossRef]

- Dire, C.; Belleney, J.; Nicolas, J.; Bertin, D.; Magnet, S.; Charleux, B.J. β-Hydrogen transfer from poly(methyl methacrylate) propagating radicals to the nitroxide SG1: Analysis of the chain-end and determination of the rate constant. J. Polym. Sci. A: Polym. Chem. 2008, 46, 6333–6345. [Google Scholar] [CrossRef]

- Souaille, M.; Fischer, H. Living Free Radical Polymerization Mediated by the Reverseible Combination of Transient Propagating and Persistent Nitroxide Radicals. The Role of Hydroxylamine and Alkene Formation. Macromolecules 2001, 34, 2830–2838. [Google Scholar] [CrossRef]

- Gryn’ova, G.; Hodgson, J.L.; Coote, M.L. Revising the mechanism of polymer autooxidation. Org. Biomol. Chem. 2011, 9, 480–490. [Google Scholar] [CrossRef] [PubMed]

- He, J.; Li, L.; Yang, Y. Effect of Hydrogen Transfer Reaction on Kinetics of Nitroxide-Mediated Free-Radical Polymerization. Macromolecules 2000, 33, 2286–2289. [Google Scholar] [CrossRef]

- Moad, G.; Anderson, A.G.; Ercole, F.; Johnson, C.H.J.; Kristina, J.; Moad, C.L.; Rizzardo, E.; Spurling, T.H.; Thang, S.H. Controlled-Growth Free-Radical Polymerization of Methylacrylate Esters: Reversible Chain Transfer versus Reversible Termination. ACS Symp. Ser. 1998, 685, 332–360. [Google Scholar]

- Burguiere, C.; Dourges, M.; Charleux, B.; Varion, J. Synthesis and Characterization of ω-Unsaturated Poly(styrene-b-n-butylmethacrylate) Block Copolymer Using TEMPO-Mediated Controlled Radical Polymerization. Macromolecules 1999, 32, 3883–3890. [Google Scholar] [CrossRef]

- Ballard, N.; Aguirre, M.; Simula, A.; Agirre, A.; Leiza, J.R.; Asua, J.M.; Es, S.V. New Class of Alkoxyamines for Efficient Controlled Homopolymerization of Methacrylates. ACS Macro Lett. 2016, 5, 1019–1022. [Google Scholar] [CrossRef]

- Ananchenko, G.S.; Fischer, H. Decomposition of model alkoxyamines in simple and polymerizing systems. 1,2,2,6,6-tetramethylpiperidinyl-N-oxyl-based compounds. J. Polym. Sci. A Polym. Chem. 2001, 39, 3604–3621. [Google Scholar] [CrossRef]

- Guillaneuf, Y.; Gigmes, D.; Marque, S.R.A.; Tordo, P.; Bertin, D. Nitroxide-Mediated Polymerization of Methyl Methacrylate Using a SG1-Based Alkoxyamine: How the Penultimate Effect Could Lead to Uncontrolled and Unliving Polymerization. Macromol. Chem. Phys. 2006, 207, 1278–1288. [Google Scholar] [CrossRef]

- McHalle, R.; Aldabbagh, F.; Zetterlund, P.B. The role of excess nitroxide in the SG1 (N-tert-butyl-N-[1-diethylphosphono-(2,2-dimethylpropyl)] nitroxide)-mediated polymerization of methyl methacrylate. Polym. Sci. A Polym. Chem. 2007, 45, 2194–2203. [Google Scholar] [CrossRef]

- Charleux, B.; Nicholas, J.; Guerret, O. Theoretical Expression of the Average Activation-Deactivation Equilibrium Constant in Controlled/Living Free-Radical Copolymerization Operating via Reversible Termination. Application to a Strongly Improved Control in Nitroxide-Mediated Polymerization of Methyl Methacrylate. Macromolecules 2005, 38, 5485–5492. [Google Scholar]

- Ananchenko, G.S.; Souaille, M.; Fischer, M.H.; Mercier, C.L.; Tordo, P. Decomposition of model alkoxyamines in simple and polymerizing systems. II Diastereomeric N-(2-methylpropyl)-N-(1-diethyl-phosphono-2,2-dimethylpropyl)-aminoxyl-based compounds. J. Polym. Sci. A Polym. Chem. 2002, 40, 3264–3283. [Google Scholar] [CrossRef]

- Nicolas, J.; Dire, P.; Mueller, L.; Belleney, J.; Charleux, B.; Marque, S.R.A.; Bertin, D.; Magnet, S.; Couvreur, L. Living Character of Polymer Chains Prepared via Nitroxide-Mediated Controlled Free-Radical Polymerization of Methyl Methacrylate in the Presence of a Small Amount of Styrene at Low Temperature. Macromolecules 2006, 39, 8274–8282. [Google Scholar] [CrossRef]

- Chauvin, F.; Couturier, J.-L.; Dulfis, P.E.; Gerard, P.; Gigmes, D.; Guerret, O.; Guillaneuf, Y.; Marque, S.R.A.; Bertin, D.; Tordo, P. Crowded Phosphonylated Alkoxyamines with Low Dissociation Temperatures: A Milestone in Nitroxide-Mediated Polymerization. ACS Symp. Ser. 2006, 944, 326–341. [Google Scholar]

- Nicolas, J.; Brusseau, S.; Charleux, B. A minimal amount of acrylonitrile turns the nitoxide-mediated polymerization of methyl methacrylate into an almost ideal controlled/living system. J. Polym. Sci. A Polym. Chem. 2010, 48, 34–47. [Google Scholar] [CrossRef]

- Chenal, M.; Mura, S.; Marchal, C.; Gigmes, D.; Charleux, B.; Fattal, E.; Couvreur, P.; Nicolas, J. Facile Synthesis of Innocuous Comb-Shaped Polymethacrylates with PEG Side Chains by Nitroxide-Mediated Radical Polymerization in Hydroalcoholic Solutions. Macromolecules 2010, 43, 9291–9303. [Google Scholar] [CrossRef]

- Lessard, B.; Ling, E.J.; Morin, M.S.T.; Maric, M. Nitroxide-mediated radical copolymerization of methyl methacrylate controlled with a minimal amount of 9-(4-vinylbenzyl)-9H-carbazole. J. Polym. Sci. A Polym. Chem. 2011, 49, 1033–1045. [Google Scholar] [CrossRef]

- Lessard, B.H.; Ling, E.J.Y.; Maric, M. Fluorescent, thermoresponsive Oligo(ethylene glycol) Methacrylate/9-(4-Vinylbenzyl)-9H-carbazole Copolymers Designed with Multiple LCSTs via Nitroxide Mediated Controlled Radical Polymerization. Macromolecules 2012, 45, 1879–1891. [Google Scholar] [CrossRef]

- Lessard, B.H.; Guillaneuf, Y.; Mathew, M.; Liang, K.; Clement, J.-L.; Gigmes, D.; Hutchinson, R.A.; Maric, M. Understanding the Controlled Polymerization of Methyl Methacrylate with Low Concentration of 9-(4-Vinylbenzyl)-9H-carbazole Comonomer by Nitroxide-Mediated Polymerization: The Pivotal Role of Reactivity Ratios. Macomolecules 2013, 46, 805–813. [Google Scholar] [CrossRef]

- Delplace, V.; Guegian, E.; Harrisson, S.; Gigmes, D.; Guillaneuf, Y.; Nicolas, J. A ring to rule them all: A cyclic kenete acetal comonomer controls the nitroxide-mediated polymerization of methacrylates and confers tunable degradability. Chem. Commun. 2015, 51, 12847–12850. [Google Scholar] [CrossRef] [PubMed]

- Tran, J.; Guegian, E.; Ibraim, N.; Harrisson, S.; Nicolas, J. Efficient synthesis of 2-methyl-4-phenyl-1,3-dioxolane, a cyclic ketene acetal for controlling the NMP of methyl methacrylate and confering tunable degradability. Polym. Chem. 2016, 7, 4427–4435. [Google Scholar] [CrossRef]

- Chauvin, F.; Dulfis, P.E.; Gigmes, D.; Guillaneuf, Y.; Marque, S.R.A.; Tordo, P.; Bertin, D. Nitroxide-Mediated Polymerization: The Pivotal Role of the kd Vlaue of the Initiating Alkoxyamine and the Importance of the Experimental Conditions. Macromolecules 2006, 39, 5238–5250. [Google Scholar] [CrossRef]

- Guillaneuf, Y.; Gigmes, D.; Marque, S.R.A.; Astolfi, P.; Greci, L.; Tordo, P.; Bertin, D. First Effective Nitroxide-Mediated Polymerization of Methyl Methacrylate. Macromolecules 2007, 40, 3108–3144. [Google Scholar] [CrossRef]

- Astolfi, P.; Greci, L.; Stipa, P.; Rizzoli, C.; Ysacco, C.; Rollet, M.; Autissier, L.; Tardy, A.; Guillaneuf, Y.; Gigmes, D. Indolinic nitroxides: Evaluation of their potential as universal control agents for nitroxide mediated polymerization. Polym. Chem. 2013, 4, 3694–3906. [Google Scholar] [CrossRef]

- Greene, A.C.; Grubbs, R.B. Synthesis and Evaluation of N-Phenylalkoxyamines for Nitroxide-Mediated Polymerization. Macromolecules 2009, 42, 4388–4390. [Google Scholar] [CrossRef]

- Fukuyama, T.; Kajihara, Y.; Ryu, I.; Studer, A. Nitroxide-Mediated Polymerization of Styrene, Butyl Acrylate, or Methyl Methacrylate by Microflow Reactor Technology. Synthesis 2012, 44, 2555–2559. [Google Scholar]

- Greene, A.C.; Grubbs, R.B. Nitroxide-Mediated Polymerization of Methyl Methacrylate and Styrene with New Alkoxyamines from 4-Nitrophenyl 2-Methylpropionat-2-yl Radicals. Macromolecules 2010, 43, 10320–10325. [Google Scholar] [CrossRef]

- Detrembleur, C.; Jerome, C.; Winter, J.D.; Gerbaux, P.; Clement, J.-L.; Guillaneuf, Y.; Gigmes, D. Nitroxide mediated polymerization of methacrylates at moderate temperatures. Polym. Chem. 2014, 5, 335–340. [Google Scholar] [CrossRef]

- Butz, S.; Baethge, H.; Schmidt-Naake, G. N-oxyl mediated free radical donor-acceptor co- and terpolymerization of styrene, cyclic maleimide monomers and n-butyl methacrylate. Macromol. Chem. Phys. 2000, 201, 2143–2151. [Google Scholar] [CrossRef]

- Edeleva, M.V.; Kirilyuk, I.A.; Zhurko, I.F.; Parkhomenko, D.A.; Tsentalovich, Y.P.; Bagryanskaya, E.G. pH-Sensitive C-NO Bond Homolysis of Alkoxyamines of Imidazoline Series with multiple Ionizable Groups as an Approach for Control of Nitroxide Mediated Polymerization. J. Org. Chem. 2011, 76, 5558–5573. [Google Scholar] [CrossRef] [PubMed]

- Bremond, P.; Marque, S.R.A. First proton triggered C-ON bond homolysis in alkoxyamines. Chem. Commun. 2011, 47, 4291–4293. [Google Scholar] [CrossRef] [PubMed]

- Bagryanskaya, E.; Bremond, P.; Edeleva, M.; Marque, S.R.A.; Parkhomenko, D.; Roubaud, V.; Siri, D. Chemically Triggered C-ON Bond Homolysis in Alkoxyamines. Part 2: DFT Investigation and Application of the pH Effect on NMP. Macromol. Rapid Commun. 2012, 33, 152–157. [Google Scholar] [CrossRef] [PubMed]

- Audran, G.; Bremond, P.; Marque, S.R.A.; Obame, G. Chemically Triggered C-ON Bond Homolysis in Alkoxyamines. 6. Effect of the Counteranion. J. Org. Chem. 2013, 78, 7754–7757. [Google Scholar] [CrossRef] [PubMed]

- Gryn’ova, G.; Smith, L.M.; Coote, M.L. Computational design of pH-switchable control agents for nitroxide mediated polymerization. Phys. Chem. Chem. Phys. 2017, 19, 22678–22683. [Google Scholar] [CrossRef] [PubMed]

- Yoshida, E. Photo-living radical polymerization of methyl methacrylate by 2,2,6,6,-tetramethylpiperidine-1-oxyl in the presence of a photo-acid generator. Colloid Polym. Sci. 2009, 287, 767–772. [Google Scholar] [CrossRef]

- Yoshida, E. Nitroxide-mediated photo-living radical polymerization of methyl methacrylate using (4-tert-butylphenyl)dipphenyl-sulfonium triflate as a photo-acid generator. Colloid Polym. Sci. 2010, 288, 239–243. [Google Scholar] [CrossRef]

- Yoshida, E. Synthesis of poly(methyl methacrylate)-block-poly(tetrahydrofuran) by photo-living radical polymerization using a 2,2,6,6,-tetramethylpiperidine-1-oxyl macromediator. Colloid Polym. Sci. 2009, 287, 1417–1424. [Google Scholar] [CrossRef]

- Yoshida, E. Stability of growing polymer chain ends for nitroxide-mediated photo-living radical polymerization. Colloid Polym. Sci. 2010, 288, 1027–1130. [Google Scholar] [CrossRef]

- Yoshida, E. Graft copolymerization of methyl methacrylate on polystyrene backbone through nitroxide-mediated photo-living radical polymerization. Colloid Polym. Sci. 2011, 289, 837–841. [Google Scholar] [CrossRef]

- Yoshida, E. Selective Controlled/Living Photoradical Polymerization of Glycidyl Methacrylate, Using a Nitroxide Mediator in the presence of a Photosensitive Triarylsulfonium Salt. Polymers 2012, 4, 1580–1589. [Google Scholar] [CrossRef]

- Yoshida, E. Photo-living radical polymerization of methyl methacrylate using alkoxyamine as an initiator. Colloid Polym. Sci. 2010, 288, 7–13. [Google Scholar] [CrossRef]

- Yoshida, E. Effects of initiators and photo-acid generators on nitroxide-mediated photo-living radical polymerization of methyl methacrylate. Colloid Polym. Sci. 2010, 288, 901–905. [Google Scholar] [CrossRef]

- Versace, D.L.; Lalevee, J.; Fouassier, J.-P.; Gigmes, D.; Guillaneuf, Y.; Bertin, D. Photosensitized alkoxyamines as bicomponent radical photoinitiators. J. Polym. Sci. A Polym. Chem. 2010, 48, 2910–2915. [Google Scholar] [CrossRef]

- Su, J.; Liu, X.; Hu, J.; You, Q.; Cui, Y.; Chen, Y. Photo-induced controlled radical polymerization of methyl methacrylate mediated by photosensitive nitroxides. Polym. Int. 2015, 64, 867–874. [Google Scholar] [CrossRef]

- Guillaneuf, Y.; Bertin, D.; Gigmes, D.; Versace, D.-L.; Lalevee, J.; Fouassier, J.-P. Toward Nitroxide-Mediated Photopolymerization. Macromolecules 2010, 43, 2204–2212. [Google Scholar] [CrossRef]

- Guillaneuf, Y.; Versace, D.L.; Bertin, D.; Lalevee, J.; Gigmes, D.; Fouassieer, J.-P. Inportance of the Position of the Chromophore Group on the Dissociation Process of Light Sensitive Alkoxyamines. Macromol. Rapid Commun. 2010, 31, 1909–1913. [Google Scholar] [CrossRef] [PubMed]

- Farina, M. Stereochemical control by inclusion polymerization. Macromol. Chem. Phys. 1981, 4, 21–35. [Google Scholar] [CrossRef]

- Isobe, Y.; Yamada, K.; Nakano, T.; Okamoto, Y. Stereocontrol in the free-radical polymerization of methacrylates with fluoroalcohols. J. Polym. Sci. A Polym. Chem. 2000, 38, 4693–4703. [Google Scholar] [CrossRef]

- Habaue, S.; Okamoto, Y. Stereocontrol in radical polymerization. Chem. Rec. 2001, 1, 46–52. [Google Scholar] [CrossRef]

- Su, J.; Liu, X.; Li, M.; Zhang, T.; Cui, Y. Stereocontrol of Methyl Methacrylate during Photoinduced Nitroxide-Mediated Polymerization in the Presence of Photosensitive Alkoxyamine. Int. J. Polym. Sci. 2016, 1, 1–8. [Google Scholar] [CrossRef]

- Morris, J.; Telitel, S.; Fairfull-Smith, K.E.; Bottle, S.E.; Lalevee, J.; Clement, J.-L.; Guillaneuf, Y.; Gigmes, D. Novel polymer synthesis methodologies using combinations of thermally- and photochemically-induced nitroxide mediated polymerization. Polym. Chem. 2015, 6, 754–763. [Google Scholar] [CrossRef]

- Tasdelen, M.A.; Moszner, N.; Yagci, Y. The use of poly(ethylene oxide) as hydrogen donor in type II photoinitiated free radical polymerization. Poylm. Bull. 2009, 63, 173–183. [Google Scholar] [CrossRef]

- Arslan, M.; Ciftci, M.; Buchmeiser, M.; Yagci, Y. Polyethylene-g-Polystyrene Copolymer by Combination of ROMP, Mn2(CO)10-Assisted TEMPO Substitution and NMRP. ACS Macro Lett. 2016, 5, 946–949. [Google Scholar]

- Kobatake, S.; Harwood, H.J.; Quick, R.P.; Priddy, D.B. Nitroxide-mediated styrene polymerization initiated by an oxoamonium chloride. J. Polym. Sci. A Polym. Chem. 1998, 36, 2555–2561. [Google Scholar] [CrossRef]

- Dao, J.; Benoit, D.; Hawker, C.J. A versatile and efficient synthesis of alkoxyamine LFR via manganese based asymmetric epoxidation catalysts. J. Polym. Sci. A Polym. Chem. 1998, 36, 2161–2167. [Google Scholar] [CrossRef]

- O’Brian, G.; Nielsen, A.; Braslau, R. Ketone Functionalized Nitroxides: Synthesis, Evaluation of N-Alkoxyamine Initiators, and Derivatization of Polymer Termini. Macromolecules 2007, 40, 7848–7854. [Google Scholar]

- Rodler, M.; Harth, E.; Rees, I.; Hawker, C.J. End-group fidelity in nitroxide-mediated living-free radical polymerizations. J. Polym. Sci. A Polym. Chem. 2000, 38, 4749–4763. [Google Scholar] [CrossRef]

- Ruehl, J.; Morimoto, C.; Stevens, D.J.; Braslau, R. Carboxylic acid- and hydroxyl-functionalized alkoxyamine initiators for nitroxide mediated radical polymerization. React. Funct. Polym. 2008, 68, 1563–1577. [Google Scholar] [CrossRef]

- Nil, N.L.; Braslau, R. Synthesis of arylethyl-functionalized N-alkoxyamine initiators and use in nitroxide-mediated radical polymerization. J. Polym. Sci. A Polym. Chem. 2007, 45, 2341–2349. [Google Scholar]

- Hawker, C.J.; Hendrik, J.L. Accurate Control of Chian End by a Novel “Living” Free-Radical Polymerization Process. Macromolecules 1995, 28, 2993–2995. [Google Scholar] [CrossRef]

- Braslau, R.; Tsimelzon, A.; Gewandter, J. Novel Methodology of the Synthesis of N-Alkoxyamines. Org. Lett. 2004, 6, 2233–2235. [Google Scholar] [CrossRef] [PubMed]

- Bosman, A.W.; Vestberg, R.; Heumann, A.; Frechter, J.M.J.; Hawker, C.J. A Modular Approach toward Functionalized Three-Dimensional Macromolecules: From Synthetic Concepts to Practical Applications. J. Am. Chem. Soc. 2003, 125, 715–728. [Google Scholar] [CrossRef] [PubMed]

- Acerbis, S.; Bertin, D.; Boutevin, B.; Gigmes, D.; Lacroix-Desmanez, P.; Mercier, C.L.; Lutz, J.-F.; Marque, S.R.A.; Siri, D.; Tordovo, P. Intramolecular Hydrogen Bonding: The Case of β-Phosphorylated Nitroxide (=Aminoxyl) Radical. Helv. Chim. Acta 2006, 89, 2119–2132. [Google Scholar] [CrossRef]

- Nicolay, R.; Marx, L.; Hemery, P.; Matyjaszewski, K. Synthesis and Evaluation of a Functional, Water- and Organo-Soluble Nitroxide for “Living” Free Radical Polymerization. Macromolecules 2007, 40, 6067–6075. [Google Scholar] [CrossRef]

- Bertin, D.; Gigmes, D.; Marque, S.R.A.; Tordo, P. Polar, Steric, and Stabilization Effects in Alkoxyamines C-ON Bond Homolysis: A Multiparameter Analysis. Macromolecules 2005, 38, 2638–2650. [Google Scholar] [CrossRef]

- Bowden, N.B.; Willets, K.A.; Moerner, W.E.; Waymouth, R.M. Synthesis of Fluorescentyl Labeled Polymers and Their Use in Single-Molecule Imaging. Macromolecules 2002, 35, 8122–8125. [Google Scholar] [CrossRef]

- Gavranovic, G.T.; Csihoni, S.; Bowden, N.B.; Hawker, C.J.; Waymouth, R.M.; Moerner, W.E.; Fuller, G.G. Well-Controlled Living Polymerization of Perylene-Labeled Polyisoprenes and Their Use in Single-Molecule Imaging. Macromolecules 2006, 39, 8121–8127. [Google Scholar] [CrossRef]

- Contrella, N.D.; Tillman, E.S. Synthesis and characterization of fluorene end-labeled polymers prepared by nitroxide-mediated polymerization. Polymer 2008, 49, 4076–4079. [Google Scholar] [CrossRef]

- Ballesteros, O.G.; Maretti, L.; Sastre, R.; Scaiano, J.C. Kinetics of Cap Separation in Nitroxide-Regulated “Living” Free Radical Polymerization: Application of a Novel Methodology Involving a Perfluorescent Nitroxide Switch. Macromolecules 2001, 34, 6184–6187. [Google Scholar] [CrossRef]

- Aspee, A.; Garcia, O.; Maretti, L.; Sastre, R.; Scaiano, J.C. Free Radical Reactions in Poly(methyl methacrylate) Films Monitored Using a Perfluorescent Quinoline-TEMPO Sensor. Macromolecules 2003, 36, 3550–3556. [Google Scholar] [CrossRef]

- Scott, M.E.; Parent, J.S.; Hennigar, S.L.; Whitney, R.A.; Cunningham, M.F. Determination of Alkoxyamine Concentrations in Nitroxyl-Mediated Styrene Polymerization Products. Macromolecules 2002, 35, 7628–7633. [Google Scholar] [CrossRef]

- Beija, M.; Charreyre, M.T.; Martinho, J.M.G. Dye-labelled polymer chains at specific sites: Synthesis by living/controlled polymerization. Prog. Polym. Sci. 2011, 36, 568–602. [Google Scholar] [CrossRef]

- Zhu, Y.; Howell, B.A.; Priddy, D.B. Nitroxide Initiated/Mediated Polymerization of Styrene: Analysis of End-Groups. Am. Chem. Soc. Polym. Prepr. Dev. Polym. Chem. 1997, 38, 97–98. [Google Scholar]

- Chmela, S.; Hrckova, L. Nitroxide mediated styrene radical polymerization using a fluorescent marked mediator. Eur. Polym. J. 2009, 45, 2580–2586. [Google Scholar] [CrossRef]

- Bucisova, L.; Yin, M.; Chmela, S.; Habicher, W.D. Nitroxide-mediated Living Radical Polymerization of Styrene with Fluorescent Initiator. J. Macromol. Sci. Part A Pure Appl. Chem. 2008, 45, 761–768. [Google Scholar] [CrossRef]

- Greene, A.C.; Grubss, R.B. Synthesis and evaluation of an ester-functional alkoxyamine for nitroxide-mediated polymerization. J. Polym. Sci. A Polym. Chem. 2009, 47, 6342–6352. [Google Scholar] [CrossRef]

- Chmela, S.; Kollar, J.; Hrckova, L. Fluorescent dye-labeled TIPNO type regulator for nitroxide mediated reversible-deactivation radical polymerization. J. Photochem. Photobiol. A Chem. 2015, 307–308, 123–130. [Google Scholar] [CrossRef]

- Binder, W.H.; Gloger, D.; Weinstabl, H.; Allmaier, G.; Pittenauer, E. Telechelic Poly(N-iospropylacrylamides) via Nitroxide-Mediated Controlled Polymerization and “Click” Chemistry: Livingness and “Grafting-from” Methodology. Macromolecules 2007, 40, 3097–3107. [Google Scholar] [CrossRef]

- Fleischmann, S.; Kronber, H.; Appelhans, D.; Voit, B.I. Diastereotopic Styrene Arrangement in the Heterosequence of Random Styrene-Ethylene Copolymer. Macromol. Chem. Phys. 2007, 208, 1050–1060. [Google Scholar] [CrossRef]

- Bernhardt, C.; Stoffelbach, F.; Charleux, B. Synthesis and use of a new alkene-functionalized SG1-based alkoxyamine. Polym. Chem. 2011, 2, 229–235. [Google Scholar] [CrossRef]

- Hentschel, J.; Bleck, K.; Ernst, O.; Lutz, J.F.; Börner, H.G. Easy Access to Bioactive Peptide-Polymer Conjugates via RAFT. Macromolecules 2008, 41, 1073–1075. [Google Scholar] [CrossRef]

- Smeek, J.M.; Otten, M.B.J.; Thies, J.; Tirell, D.A.; Stunnenberg, H.G.; Hest, J.C.M.V. Controlled Assembly of Macromolecular β-Sheet Fibrils. Angew. Chem. 2005, 117, 2004–2007. [Google Scholar] [CrossRef]

- Boerner, G.; Smarsly, B.M.; Rank, A.; Schubert, R.; Geng, Y.; Discher, D.E.; Hellweg, T.; Brandt, A. Organization of Self-Assembled Peptide-Polymer Nanofibers in Solution. Macromolecules 2008, 41, 1430–1437. [Google Scholar] [CrossRef]

- Kessel, S.; Thomas, A.; Börner, H.G. Mimicking Biosilification: Programmed Coassembly of Peptide-Polymer Nanotapes and Silica. Angew. Chem. Int. Ed. 2007, 46, 9023–9026. [Google Scholar] [CrossRef] [PubMed]

- Paira, T.K.; Banerjee, S.; Raula, M.; Kotal, A.; Si, S.; Mandal, T.K. Peptide-Polymer Bioconjugates via Atom Transfer Radical Polymerization and Their Solution Aggregation into Hyrid/Nanospheres for Dye Uptake. Macromolecules 2010, 43, 4050–4061. [Google Scholar] [CrossRef]

- Wester, H.-J.; Kessler, H. Molecular Targeting with Peptides or Peptide-Polymer Conjugates: Just a Question of Size? J. Nucl. Med. 2005, 46, 1940–1945. [Google Scholar] [PubMed]

- Kühnle, H.; Börner, H.G. Biotransformation an Polymer-Peptid-Konjugaten—Ein universelles Werkzeug zur Mikrostrukturkontrolle. Angew. Chem. 2009, 121, 6552–6556. [Google Scholar] [CrossRef]

- Chenal, M.; Boursier, C.; Guillaneuf, Y.; Taverana, M.; Couvreur, P.; Nicolas, J. First peptide/protein PEGylation with functional polymers designed by nitroxide-mediated polymerization. Polym. Chem. 2011, 2, 1523–1530. [Google Scholar] [CrossRef]

- Molawi, K.; Studer, A. Reversible switching of substrate activity of poly-N-isopropylacrylamide peptide conjugates. Chem. Commun. 2007, 48, 5173–5175. [Google Scholar] [CrossRef] [PubMed]

- Moller, M.; Hentschel, C.; Chi, X.; Studer, A. Aggregation behaviour of peptide-polymer conjugates containing linear peptide backbones and multiple polymer side chains prepared by nitroxide-mediated radical polymerization. Org. Biomol. Chem. 2011, 9, 2403–2412. [Google Scholar] [CrossRef] [PubMed]

- Trimaille, T.; Mabrouk, K.; Monnier, V.; Charles, L.; Bertin, D.; Gigmes, D. SG1-Functionalized Peptides as Precursors for Polymer-Peptide Conjugates: A Straightforward Approach. Macromolecules 2010, 43, 4864–4870. [Google Scholar] [CrossRef]

- Garcia-Valdez, O.; George, S.; Champagne-Hertley, R.; Saldivar-Guerra, E.; Champagne, P.; Cunningham, M.F. Chitosan modification via nitroxide-mediated polymerization and grafting to approach in homogeneous media. Polymer 2015, 67, 139–147. [Google Scholar] [CrossRef]

- Garcia-Valdez, O.; Champagne-Hertley, R.; Saldivar-Guerra, E.; Champagne, P.; Cunningham, M.F. Modification of chitosan with polystyrene and poly(n-butyl acrylate) via nitroxide-mediated polymerization and grafting from approach in homogeneous media. Polym. Chem. 2015, 6, 2827–2836. [Google Scholar] [CrossRef]

- Hua, D.; Deng, W.; Tang, J.; Cheng, J.; Zhu, X. A new method of controlled grafting modification of chitosan via nitroxide-mediated polymerization using chitosan-TEMPO macroinitiator. Int. J. Biol. Macromol. 2008, 43, 43–47. [Google Scholar] [CrossRef] [PubMed]

- Jiang, J.; Hua, D.; Tang, J.; Zhu, X.L. Synthesis and propety of poly(sodium 4-styrenesulfonate) grafted chitosan by nitroxide-mediated polymerization with chitosan-TEMPO macroinitiator. Carbohydr. Polym. 2010, 81, 358–364. [Google Scholar] [CrossRef]

- Lefay, C.; Guillaneuf, Y.; Morreira, G.; Thevarajah, Y.Y.; Castignoles, P.; Ziarelli, F. Heterogeneous modification via nitroxide-mediated polymerization. Polym. Chem. 2013, 4, 322–328. [Google Scholar] [CrossRef]

- Audran, G.; Bagryanskaya, E.G.; Bremond, P.; Edeleva, M.V.; Marque, S.R.A.; Parkhomenko, D.A.; Rogozhnikova, O.Y.; Tormyshev, V.M.; Tretyakov, E.V.; Trukhin, D.V.; et al. Trityl-based alkoxyamines as NMP controllers and spin-labels. Polym. Chem. 2016, 7, 6490–6499. [Google Scholar] [CrossRef] [PubMed]

- Szydlowska, J.; Pietrasik, K.; Glaz, L.; Kaim, A. An ESR study of biradicals formed from two 4-amino-TEMPO linked by -(CH2)n-, (n = 2,3,4,6). Chem. Phys. Lett. 2008, 460, 245–252. [Google Scholar] [CrossRef]

- Ruehl, J.; Hill, N.L.; Walter, E.D.; Millhauser, G.; Braslau, R. A Proximal Bisnitroxide Initiator: Studies in Low-Temperature Nitroxide-Mediated Polymerizations. Macromolecules 2008, 41, 1972–1982. [Google Scholar] [CrossRef] [PubMed]

- Marque, S.R.A.; Siri, D. Is Experimental Evidence Sufficient Enough To Account for the Stabilization Effect of Bisnitroxide on the Fate of NMP Experiments? Macromolecules 2009, 42, 1404–1406. [Google Scholar] [CrossRef]

- Kaim, A.; Szydlowska, J.; Pietrasik, K. The effect of the spacer length on binitroxide radical polymerization of styrene. Macromol. Res. 2011, 19, 1041–1047. [Google Scholar] [CrossRef]

- Pietrasik, K.; Swiatkowska, O.; Kaim, A. Direct synthetic route for water-dispersible polythiophene nanoparticles via surfactant-free oxidative polymerization. Polymer 2010, 55, 812–816. [Google Scholar]

- Kaim, A.; Pietrasik, K.; Stoklosa, T. N,N′-Diaminoethane linked bis-TEMPO-mediated free radical polymerization of styrene. Eur. Polym. J. 2010, 46, 519–527. [Google Scholar] [CrossRef]

- Huang, W.; Chiarelli, R.; Charleux, B.; Rassat, A.; Vairon, J.-P. Unique Behaviour of Nitroxide Biradicals in the Controlled Radical Polymerization of Styrene. Macromolecules 2002, 35, 2305–2317. [Google Scholar] [CrossRef]

- Lizotte, J.R.; Anderson, S.G.; Long, T.E. Novel dinitroxide mediating agent for stable free-radical polymerization. J. Polym. Sci. A: Polym. Chem. 2004, 42, 1547–1556. [Google Scholar] [CrossRef]

- Hill, N.L.; Breslau, R. Synthesis and Characterization of a Novel Bisnitroxide Initiator for Effecting “Outside-In” Polymerization. Macromolecules 2005, 38, 9066–9074. [Google Scholar] [CrossRef]

- Dulfis, P.-E.; Chagneux, N.; Gigmes, D.; Trimaille, T.; Marque, S.R.A.; Bertin, D.; Tordo, P. Intermolecular radical addition of alkoxyamines onto olefins: An easy access to advanced macromolecular architectures precursors. Polymer 2007, 48, 5219–5225. [Google Scholar]

- Miura, Y.; Dairoku, M. Synthesis and characterization of 6- and 12-arm star polymers by nitroxide-mediated radical polymerization of St and MA from dendritic TIPNO-based hexafunctional and dodecafunctional macroinitiator. J. Polym. Sci. A Polym. Chem. 2007, 45, 4364–4376. [Google Scholar] [CrossRef]

- Tortosa, K.; Smith, J.A.; Cunningham, M.F. Synthesis of Polystyrene-block-poly(butyl acrylate) Copolymers Using Nitroxide-Mediated Living Radical Polymerization in Miniemulsion. Macromol. Rapid Commun. 2001, 22, 957–961. [Google Scholar] [CrossRef]

- Nicolas, J.; Charleux, B.; Guerret, O.; Magnet, S. Nitroxide-Mediated Controlled Free-Radical Emulsion Polymerization of Styrene and n-Butyl Acrylate with a Water-Soluble Alkoxyamine as Initiator. Angew. Chem. Int. Ed. 2004, 43, 6186–6189. [Google Scholar] [CrossRef] [PubMed]

- Marx, L.; Henrey, P. Synthesis and evaluation of a new polar, TIPNO type nitroxide for “living” free radical polymerization. Polymer 2009, 50, 2752–2761. [Google Scholar] [CrossRef]

- Tan, W.; Tsarevski, N.V.; Matjyaszewski, K. Determination of equilibrium constants for atom transfer radical polymerization. J. Am. Chem. Soc. 2006, 128, 1598–1604. [Google Scholar]

- Bubak, M.; Morik, J. Equilibrium constants and activation rate coefficients for atom tranfer radical polymerization at pressures up to 2500 bar. Macromol. Chem. Phys. 2010, 211, 2154–2161. [Google Scholar] [CrossRef]

- Matjyaszewski, K. Atom transfer radical polymerization (ATRP): Current status and future perspectives. Macromolecules 2002, 45, 4015–4039. [Google Scholar] [CrossRef]

- Fischer, H. The persistent radical effect, a principle for selective radical reactions and living radical polymerizations. Chem. Rev. 2001, 101, 3581–3610. [Google Scholar] [CrossRef] [PubMed]

- Paoli, P.D.; Isse, A.A.; Bartolomei, N.; Gennaro, A. New Insights into the mechanism of activation of atom transfer radical polymerization by Cu(I) complexes. Chem. Commun. 2011, 47, 3580–3582. [Google Scholar] [CrossRef] [PubMed]

- Braunecker, W.A.; Matjyaszewski, K. Recent mechanistic developments in atom transfer radical polymerization. J. Mol. Catal. A Chem. 2006, 254, 155–164. [Google Scholar] [CrossRef]

- Lin, C.Y.; Coote, M.L.; Gennaro, A.; Matjyaszewski, K. Ab Initio Evaluation of the Thermodynamic and Electrochemical Properties of Alkyl Halides and Radicals and Polymerization. J. Am. Chem. Soc. 2008, 12, 12762–12774. [Google Scholar] [CrossRef] [PubMed]

- Seeliger, F.; Matjyaszewski, K. Temperure effect on activation rate constants in ATRP: New mechanistic insights into the activation process. Macromolecules 2009, 42, 6050–6055. [Google Scholar] [CrossRef]

- Isse, A.A.; Gennaro, A.; Lin, C.Y.; Hodgson, J.L.; Coote, M.L.; Guliashivili, T. Mechanism of carbon-halogen bond reductive cleavage in activated alkyl halide initiators relevant to living radical polymerizatio: Theoretical and experimental study. J. Am. Chem. Soc. 2011, 133, 6254–6264. [Google Scholar] [CrossRef] [PubMed]

- Abdirisak, A.I.; Bortolamei, N.; Paoli, P.D.; Gennaro, A. On the mechanism of activator of copper-catalyzed atom transfer radical polymerization. Electrochim. Acta 2013, 110, 655–662. [Google Scholar]

- Jakubowski, W.; Matjyaszewski, K. Activators regenerated by electron transfer for atom transfer radical polymerization of (meth)acylates and related block copolymers. Angew. Chem. Int. Ed. 2006, 45, 4482–4486. [Google Scholar] [CrossRef] [PubMed]

- Matjyaszewski, K.; Jakubowski, W.; Min, K.; Tang, W.; Huang, J.H.; Braunecker, W.A.; Tsarevsky, N.V. Diminishing Catlyst concentration in atom transfer radical polymerization with reducing agents. Proc. Nat. Acad. Sci. USA 2006, 103, 15309–15314. [Google Scholar] [CrossRef] [PubMed]

- Konkolewicz, K.; Magneau, A.J.D.; Averik, S.E.; Simokava, A.; He, H.K.; Matjyaszewski, K. ICAR ATRP with ppm Cu catlyst in water. Macromolecules 2012, 45, 4461–4468. [Google Scholar] [CrossRef]

- Magneau, A.J.D.; Strandwitz, N.C.; Gennaro, A.; Matjyaszewski, K. Electrochemically mediated atom transfer radical polymerization. Science 2011, 332, 81–84. [Google Scholar] [CrossRef] [PubMed]

- Bortolamei, N.; Isse, A.A.; Magneau, A.J.D.; Gennaro, A.; Matjyaszewski, K. Controlled Aqueous atom transfer radical polymerization with electrochemical generation of the active catalyst. Angew. Chem. Int. Ed. 2011, 50, 11391–11394. [Google Scholar] [CrossRef] [PubMed]

- Abreu, C.M.R.; Mendonca, P.V.; Serra, A.C.; Popov, A.V.; Matjyaszewski, K.; Guliashvili, T.; Coelho, J.F.J. Inorganic sulfites: Efficient reducing agents and supplemental aactivators for atom transfer radical polymerization. ACS Macro Lett. 2012, 1, 1308–1311. [Google Scholar] [CrossRef]

- Konkolewicz, D.; Wang, Y.; Zhong, M.; Krys, P.; Isse, A.A.; Gennaro, A.; Matjyaszewski, K. Reversible-deactivation radical polymerization in the presence of metallic copper. A critical assessment of the SARA ATRP and SET-LRP mechanisms. Macromolecules 2013, 46, 8749–8772. [Google Scholar] [CrossRef]

- Guliashvili, T.; Mendonca, P.V.; Serra, A.C.; Popov, A.V.; Coehlo, J.F.J. Copper mediated controlled living radical polymerization in polar solvents: Insights into some relevant mechanistic aspects. Chem. Eur. J. 2012, 18, 4607–4612. [Google Scholar] [CrossRef] [PubMed]

- Perce, V.; Guliashvili, T.; Ladislaw, J.S.; Wistrand, A.; Stjerndahl, A.; Sienkowska, M.J.; Monteiro, M.J.; Sahoo, S. Ultrafast Synthesis of ultralight molar mass polymers by metal-catalyzed living radical polymerization of acrylates, methacrylates and vinyl chloride mediated by SET at 25 °C. J. Am. Chem. Soc. 2006, 128, 14156–14165. [Google Scholar] [CrossRef] [PubMed]

- Yilmaz, G.; Iskin, B.; Yagci, Y. Photo-induced Copper(I)-Catalyzed Click Chemistry by Electron transfer Process Using Polynuclear Aromatic Compounds. Macromol. Chem. Phys. 2014, 215, 662–668. [Google Scholar] [CrossRef]

- Guan, Z.; Smart, B.; Remarkable, A. Remarkable Visible Light Effect on Atom-Transfer Radcial Polymerization. Macromolecules. 2000, 33, 6904–6906. [Google Scholar] [CrossRef]

- Pan, X.; Malhotra, M.; Simakova, A.; Wang, Z.; Konkolewicz, D.; Matjyaszewski, K. Photoinduced Atom Transfer Radical Polymerization with ppm-Level Cu Catalyst by Visible Light in Aqueous Media. J. Am. Chem. Soc. 2015, 137, 15430–15433. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Zhang, Z.; Parker, B.; Matjyaszewski, K. ATRP of MMA with ppm Levels of Iron Catalyst. Macromolecules 2011, 44, 4022–4025. [Google Scholar] [CrossRef]

- Taskin, O.S.; Yilmaz, G.; Tasdelen, M.A.; Yagci, Y. Photo-induced reverse atom transfer radical polymerization of methylmethacrylate using camphorquinone/benzhodryl system. Polym. Int. 2014, 63, 902–907. [Google Scholar] [CrossRef]

- Tasdelen, M.A.; Ciftci, M.; Yagci, Y. Visible Light-Induced Atom Transfer Radical Polymerization. Macromol. Chem. Phys. 2012, 213, 1391–1396. [Google Scholar] [CrossRef]

- Konkolewicz, D.; Schroeder, K.; Buback, J.; Matjyaszewski, K. Visible Light and Sunlight Photo-induced ATRP with ppm of Cu Catalyst. ACS Macro Lett. 2012, 1, 1219–1223. [Google Scholar] [CrossRef]

- Discekici, E.; Anastasaki, A.; Kaminker, R.; Willenbacher, J.; Truong, N.P.; Fleischmann, C.; Oschmann, B.; Lunn, D.J.; Alaniz, J.R.D.; Davis, T.P.; et al. Light Mediated Atom Transfer Radical Polymerization of Semi-Fluorinated (Meth)acrylates: Facile Access to functional Materials. J. Am. Chem. Soc. 2017, 139, 5939–5945. [Google Scholar] [CrossRef] [PubMed]

- Tasdelen, M.A.; Uygun, M.; Yagci, Y. Studies on Photoinduced ATRP in the presence of Photoinitiator. Macromol. Chem. Phys. 2011, 212, 2036–2042. [Google Scholar] [CrossRef]

- Yagci, Y.; Tasdelen, M.A.; Jokusch, S. Recduction of Cu(II) by photochemically generated phosphonyl radicals to generate Cu(I) as catalyst for atom transfer radical polymerization and azide-alkyne cycloaddition click reactions. Polymer 2014, 55, 3468–3474. [Google Scholar] [CrossRef]

- Ciftci, M.; Tasdelen, M.A.; Yagci, Y. Sunlight induced atom transfer radical polymerization by using dimanganese decacarbonyl. Polym. Chem. 2014, 5, 600–606. [Google Scholar] [CrossRef]

- Dadashi-Silab, S.; Tasdelen, M.A.; Kiskan, B.; Wang, X.; Antonietti, M.; Yagci, Y. Photochemically Mediated Atom Transfer Radical Polymerization Using Polymeric Semiconductor Mesoporous Graphitic Carbon Nitride. Macromol. Chem. Phys. 2014, 215, 675–681. [Google Scholar] [CrossRef]

- Dadashi-Silab, S.; Tasdelen, M.A.; Asiri, A.M.; Khan, S.B.; Yagci, Y. Photoinduced Atom Transfer Radical Polymeriztion Using Semiconductor Nanoparticles. Macromol. Rapid Commun. 2014, 35, 454–459. [Google Scholar] [CrossRef] [PubMed]

- Kork, S.; Ciftci, M.; Tasdelen, M.A.; Yagci, Y. Photoinduced Cu(0)-Mediated Atom Transfer Radical Polymerization. Macromol. Chem. Phys. 2016, 217, 812–817. [Google Scholar] [CrossRef]

- Fors, B.P.; Hawker, C.J. Control of a Living Radical Polymerization of Methacrylates by Light. Angew. Chem. Int. Ed. 2012, 51, 8850–8853. [Google Scholar] [CrossRef] [PubMed]

- Theriot, J.C.; Lim, C.-H.; Yang, H.; Ryan, M.D.; Musgrave, C.B.; Miyake, G.M. Organocatalyzed atom transfer radical polymerization driven by visible light. Science 2016, 27, 1082–1086. [Google Scholar] [CrossRef] [PubMed]

- Treat, N.J.; Sprafke, H.; Kramer, J.W.; Clark, P.G.; Berton, B.E.; Alaniz, J.R.D.; Fors, B.P.; Hawker, C.J. Metal-Free Atom Transfer Radical Polymerization. J. Am. Chem. Soc. 2014, 136, 16096–16101. [Google Scholar] [CrossRef] [PubMed]

- Dadashi-Silab, S.; Pan, X.; Matjyaszewski, K. Phenyl Benzo[b]phenothiazine as a Visible Light Photoredox Catalyst for Metal-Free Atom Transfer Radical Polymerization. Chem. Eur. J. 2017, 23, 5972–5977. [Google Scholar] [CrossRef] [PubMed]

- Pearson, R.M.; Lim, C.-H.; McCarthy, B.G.; Musgrave, C.B.; Miyake, G.M. Organocatalyzed Atom Transfer Radical Polymerization Using N-Aryl Phenoxazines as Photoredox Catalysts. J. Am. Chem. Soc. 2016, 138, 11399–11407. [Google Scholar] [CrossRef] [PubMed]

- Lim, C.-H.; Ryan, M.D.; McCarthy, B.G.; Thierot, J.C.; Sartor, S.M.; Damrauer, N.H.; Musgrave, C.B.; Miyake, G.M. Intramolecular Charge Transfer and Ion Pairing in N,N-Diaryl Dihydrophenazine Photoredox Catalysts for Efficient Organocatalyzed Atom Transfer Polymerization. J. Am. Chem. Soc. 2017, 139, 348–355. [Google Scholar] [CrossRef] [PubMed]

- Allushi, A.; Jokusch, S.; Yilmaz, G.; Yagci, Y. Photo-initiated Metal-Free Controlled/Living Radical Polymerization Using Polynuclear Aromatic Hydrocarbons. Macromolecules 2016, 49, 7785–7792. [Google Scholar] [CrossRef]

- Kutahya, C.; Allushi, A.; Isci, R.; Kreutzer, J.; Öztürk, T.; Yilmaz, G.; Yagci, Y. Photoinduced Metal-Free Atom Transfer Radical Polymerization Using Highly Conjugated Thiophene Derivatives. Macromolecules 2017, 50, 6903–6910. [Google Scholar] [CrossRef]

- Kutahya, C.; Aykac, F.; Yilmaz, G.; Yagci, Y. Using reducible dyes in the presence of amines. Polym. Chem. 2016, 7, 6094–6098. [Google Scholar] [CrossRef]

- Theriot, J.C.; McCarthy, B.G.; Lim, C.-H.; Miyake, G.M. Organocatalyzed Atom Transfer Radical Polymerization: Perspectives on Catalyst Design and Performance. Macromol. Rapid Commun. 2017, 38, 1700040. [Google Scholar] [CrossRef] [PubMed]

- Allushi, A.; Kütahya, C.; Aydogan, C.; Kreutzer, J.; Yilmaz, G.; Yagci, Y. Conventional Type II photo-initiators as activators for photo-induced metal-free atom transfer radical polymerization. Polym. Chem. 2017, 8, 1972–1977. [Google Scholar] [CrossRef]

- Niu, T.; Jiang, J.; Li, S.; Ni, B.; Liu, X.; Chen, M. Well-Defined High-Molecular-Weight Polyacrylontrile Formation via Visible-Light-Induced Metal-Free Radical Polymerization. Macromol. Chem. Phys. 2017, 218, 1700169. [Google Scholar] [CrossRef]

- Liu, X.D.; Zhang, L.F.; Cheng, Z.P.; Zhu, X.L. Metal-free photo-induced electron transfer-atom transfer radical polymerization (PET-ATRP) via a visible light organic photocatalyst. Polym. Chem. 2016, 7, 689–700. [Google Scholar] [CrossRef]

- Miyake, G.M.; Thierot, J.C. Perylene as an Organic Photocatalyst for the Radical Polymerization of Functionalized Vinyl Monomers through Oxidative Quenching with Alkyl Bromides and Visible Light. Macromolecules 2014, 47, 8255–8261. [Google Scholar] [CrossRef]

- Huang, Z.; Gu, Y.; Liu, X.; Zhang, L.; Cheng, Z.; Zhu, X. Metal-Free Atom Transfer Radical Polymerization of Methyl Methacrylate with ppm Level of Organic Photocatalyst. Macromol. Rapid Commun. 2017, 38, 1600461–1600469. [Google Scholar] [CrossRef] [PubMed]

- Tsaversky, N.V.; Braunecker, W.A.; Matjyaszewski, K. Electron transfer reaction relevant to atom transfer radical polymerization. J. Organomet. Chem. 2007, 692, 3212–3222. [Google Scholar]

- Ryan, M.D.; Pearson, R.M.; French, T.A.; Miyake, G.M. Impact of Light on Control in Photoinduced Organocatalyzed Atom Transfer Radical Polymerization. Macromolecules 2017, 50, 4616–4662. [Google Scholar] [CrossRef]

- Borska, K.; Moravcikova, D.; Mosnacek, J. Photochemically Induced ATRP of (Meth)Acrylates in the Presence of Air: The Effect of Light Intensity, Ligand, and Oxygen Concentration. Macromol. Rapid Commun. 2017, 38, 1600639. [Google Scholar] [CrossRef] [PubMed]

- Wallentin, C.-J.; Nguyen, J.D.; Finkbeiner, P.; Stephenson, C.R. Visible Light-Mediated Atom Tranfer Radical Addition via Oxidative and Reductive Quenching of Photocatalyst. J. Am. Chem. Soc. 2012, 134, 8875–8884. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, J.D.; Tucker, J.W.; Konieczynska, M.D.; Stephenson, C.R. Intermolecular Atom Transfer Radical Addition to Olefins Mediated by Oxidative Quenching of Photoredox Catalysts. J. Am. Chem. Soc. 2011, 133, 4160–4163. [Google Scholar] [CrossRef] [PubMed]

- Pan, X.; Fang, C.; Fantini, M.; Malhotra, N.; So, W.Y.; Peteanu, L.A.; Isse, A.A.; Gennaro, A.; Liu, P.; Matjyaszewski, K. Mechanism of Photo-induced Metal-Free Atom Transfer Radical Polymerization: Experimental and Computational Studies. J. Am. Chem. Soc. 2016, 138, 2411–2425. [Google Scholar] [CrossRef] [PubMed]

- Jokusch, S.; Yagci, Y. The Active Role of Excited States of Phenothiazines in Photo-induced Metal Free Atom Transfer Polymerization: Singlet or Triplet States? Polym. Chem. 2016, 7, 6039–6043. [Google Scholar] [CrossRef]

- Dadashi-Silab, S.; Tasdelen, M.A.; Yagci, Y. Photoinitiated atom transfer radical polymerization: Current status and future perspectives. J. Polym. Sci. A Polym. Chem. 2014, 52, 2878–2888. [Google Scholar] [CrossRef]

- Goto, A.; Tsujii, Y.; Kaji, H. Reversible Complexation Mediated Polymerization (RCMP) of Methyl Methacrylate. In Progress in Controlled Radical Polymerization: Mechanism and Techniques; ACS: Washington, DC, USA, 2012; Volume 20, pp. 305–315. [Google Scholar]

- Goto, A.; Hirai, N.; Nagasawa, K.; Tsujii, Y.; Fukuda, T.; Kaji, H. Phenols and Carbon Compounds as Efficient Organic Catalyst for Reversible Chain Transfer Catalyzed Living Radical Polymerization (RTCP). Macromolecules 2010, 43, 7971–7978. [Google Scholar] [CrossRef]

- Goto, A.; Nagasawa, K.; Shinjo, A.; Tsuji, Y.; Fukuda, T. Reversible Chain Transfer Catalyzed Polymerization of Methyl Methacrylate with In-Situ Formed Alkyl Iodide Initiator. Aust. J. Chem. 2009, 62, 1492–1495. [Google Scholar] [CrossRef]

- Goto, A.; Zushi, H.; Hirai, N.; Wakada, T.; Tsuji, Y.; Fukuda, T. Living Radical Polymerization with Germanium, Tin and Phosphorus Catalysts - Reversible Chain Transfer Catalyzed Polymerization (RTCPs) J. Am. Chem. Soc. 2007, 129, 13347–13354. [Google Scholar] [CrossRef] [PubMed]

- Yorizane, M.; Nagasuga, T.; Kitayama, Y.; Tanaka, A.; Minami, H.; Goto, A.; Fukuda, T.; Okubo, M. Reversible Chain Transfer Catalyzed Polymerization (RTCP) of Methyl Methacrylate with Nitrogen Catalyst in an Aqueous Microsuspension System. Macromolecules 2010, 43, 8703–8705. [Google Scholar] [CrossRef]

- Goto, A.; Ohtsuki, A.; Ohfuji, H.; Tanishima, M.; Kaji, H. Reversible Generation of a Carbon-Centered Radical from Alkyl Iodide Using Organic Salts and Their Application as Organic Catalysts in Living Radical Polymerization. J. Am. Chem. Soc. 2013, 135, 11131–11139. [Google Scholar] [CrossRef] [PubMed]

- Goto, A.; Suzuki, T.; Ohfuju, H.; Tanishima, M.; Fukuda, T.; Tsujii, Y.; Kaji, H. Reversible Complexation Mediated Living Radical Polymerization (RCMP) Using Organic Catalysts. Macromolecules 2011, 44, 8709–8715. [Google Scholar] [CrossRef]

- Discekici, E.H.; Pester, C.W.; Treat, N.J.; Lawrence, J.; Mattson, K.M.; Narupai, B.; Toumayan, E.P.; Luo, Y.; McGrath, A.J.; Clark, P.G.; et al. Simple Benchtop Approach to Polymer Brush Nanostructures Using Visible-Light-Mediated Metal-Free Atom Transfer Radical Polymerization. ACS Macro Lett. 2016, 5, 258–262. [Google Scholar] [CrossRef]

- Ma, L.; Li, N.; Zhu, J.; Chen, X. Visible Light-Induced Metal Free Surface Initiated Atom Transfer Radical Polymerization of Methyl Methacrylate on SBA-15. Polymers 2017, 9, 58. [Google Scholar] [CrossRef]

- Yan, J.; Pan, X.; Schmitt, M.; Wang, Z.; Bockstaller, M.R.; Matyjaszewski, K. Enhancing Initiation Efficiency in Metal-Free Surface-Initiated Atom Transfer Radical Polymerization (SI-ATRP). ACS Macro Lett. 2016, 5, 661–665. [Google Scholar] [CrossRef]

- Yang, Y.; Liu, X.; Ye, G.; Zhu, S.; Wang, Z.; Huo, X.; Matyjaszewski, K.; Lu, Y.; Chen, J. Metal-Free Photo-induced Electron Transfer-Atom Transfer Radical Polymerization Integrated with Bioinspired Polydopamine Chemistry as a Green Strategy for Surface Engineering of Magnetic Nanoparticles. Appl. Mater. Interfaces 2017, 9, 13637–13646. [Google Scholar] [CrossRef] [PubMed]

- Zeng, G.; Liu, M.; Heng, C.; Huang, Q.; Mao, L.; Huang, H.; Hui, J.; Deng, F.; Zhang, X.; Wei, Y. Applied Surface Science Surface polyPEGylation of Eu3+ doped luminescent hydroxyapatite nanorods through the combination of ligand exchange and metal free surface initiated atom transfer radical polymerization. Appl. Surf. Sci. 2017, 399, 499–505. [Google Scholar] [CrossRef]

- Zeng, G.; Liu, M.; Shi, K.; Heng, C.; Mao, L.; Wang, Q.; Huang, H.; Deng, F.; Zhang, X.; Wei, Y. Surface modification of nanodiamond through metal free atom transfer radical polymerization. Appl. Surf. Sci. 2016, 390, 710–717. [Google Scholar] [CrossRef]

- Ramsey, B.L.; Pearson, R.M.; Beck, L.R.; Miyake, G.M. Photo-induced Organocatalyzed Atom Transfer Radical Polymerization Using Continuous Flow. Macromolecules 2017, 50, 2668–2674. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Yuan, L.; Wang, Z.; Rahman, M.A.; Huang, Y.; Zhu, T.; Wang, R.; Cheng, J.; Wang, C.; Chu, F.; et al. Photo-induced Metal-Free Atom Transfer Radical Polymerization of Biomass-Based Monomers. Macromolecules 2016, 49, 7709–7717. [Google Scholar] [CrossRef]

- Ding, W.; Wang, S.; Yao, K.; Ganewatta, M.S.; Tang, C.; Robertson, M.S. Physical Behavior of Triblock Copolymer Thermoplastic Elastomers Containing Sustainable Rosin-Derived Polymethacrylate End Blocks. ACS Sustain. Chem. Eng. 2017, 5, 11470–11480. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, Y.; Yuan, L.; Hayat, J.; Trenor, N.M.; Lamm, M.E.; Vlaminck, L.; Bilet, S.; Du Prez, F.E.; Wang, Z.; et al. Biomass Approach toward Robust, Sustainable, Multi-Shape-Memory Materials. ACS Macro Lett. 2016, 5, 602–606. [Google Scholar] [CrossRef]

- Yu, J.; Liu, X.; Wang, C.; Wang, J.; Chu, F.; Tang, C. Integration of renewable cellulose and rosin towards sustainable copolymers by “grafting from” ATRP. Green Chem. 2014, 16, 1854–1864. [Google Scholar] [CrossRef]

- Liu, Y.; Yao, K.; Chen, X.; Wang, J.; Wang, Z.; Ploehn, H.J.; Wang, C.; Chu, F.; Tang, C. Sustainable thermoplastic elastomers derived from renewable cellulose, rosin and fatty acids. Polym. Chem. 2014, 5, 3170–3181. [Google Scholar] [CrossRef]

- Caramli, S.; Murata, H.; Amemiya, E.; Matyjaszewski, K.; Russel, A.J. Tertiary Structure-Based Predicition of How ATRP Initiators react with Proteins. ACS Biomater. Sci. Eng. 2017, 3, 2086–2087. [Google Scholar] [CrossRef]

- Pan, X.; Lathwal, S.; Mack, S.; Yan, J.; Das, S.R.; Matyjaszewski, K. Automated Synthesis of Well-Defined Polymers and Biohybrids by Atom Transfer Radical Polymerization Using a DNA Synthesizer. Angew. Chem. Int. Ed. 2017, 56, 2740–2743. [Google Scholar] [CrossRef] [PubMed]

- Cohen-Karni, D.; Kovaliov, M.; Ramelot, T.; Konkolewicz, D.; Graner, S.; Averick, S. Grafting challenging monomers from proteins using aqueous ICAR ATRP under bio-relevant conditions. Polym. Chem. 2017, 8, 3992–3998. [Google Scholar] [CrossRef]

- Chiefari, J.; Chong, Y.K.C.; Ercole, F.; Krstina, J.; Jeffery, J.; Le, T.P.; Mayadunne, R.T.; Moad, G.F.; Moad, C.L. Living Free-Radical Polymerization by Reversible Addition-Fragmentation Chain transfer: The RAFT Process. Macromolecules 1998, 31, 5559–5562. [Google Scholar] [CrossRef]

- Müller, A.H.E.; Zhuang, R.; Yan, D.; Litvenko, G. Kinetic Analysis of “Living” Polymerization Processes Exhibiting Slow Equilibria. 1. Degenerative Transfer (Direct Activity Exchange between Active and “Dormant” Species). Application to Group Transfer. Macromolecules 1995, 28, 4326–4333. [Google Scholar] [CrossRef]

- Litvenko, G.; Müller, A.H.E. General Kinetic Analysis and Comparison of Molecular Weight Distributions for Various Mechanisms of Activity Exchange in Living Polymerization. Macromolecules 1997, 30, 1253–1266. [Google Scholar] [CrossRef]

- Moad, G.; Rizzardo, E.; Thang, S.H. Radical addition-fragmentation chemistry in polymer synthesis. Polymer 2008, 49, 1079–1131. [Google Scholar] [CrossRef]

- Bicciocchi, E.; Chong, Y.K.; Giorgini, L.; Moad, G.; Rizzardo, E.; Thang, S.H. Substitution Effects on RAFT Polymerization with Benzyl Aryl Trithiocarbonates. Macromol. Chem. Phys. 2010, 211, 529–538. [Google Scholar] [CrossRef]

- Moad, G.; Chiefari, J.; Moad, C.L.; Postma, A.; Mayadunne, R.T.A.; Rizzardo, E.; Thang, S.H. Initiating free radical polymerization. Macromol. Symp. 2002, 182, 65–80. [Google Scholar] [CrossRef]

- Moad, G.; Chiefari, J.; Chong, B.Y.K.; Krstina, J.; Mayudanne, R.T.A.; Postma, A.; Rizzardo, E.; Thang, S.H. Living free radical polymerization with reversible addition—Fragmentation chain transfer (the life of RAFT) Polym. Int. 2000, 49, 993–1001. [Google Scholar]

- Barner-Kowollik, C.; Quinn, J.F.; Nguyen, T.L.U.; Heuts, J.P.A.; Davis, T.P. Kinetic Investigations of Reversible Addition Fragmentation Chain Transfer Polymerization: Cumyl Phenyldithioacetate Mediated Homopolymerizations of Styrene and Methyl Methacrylate. Macromolecules 2001, 34, 7849–7857. [Google Scholar] [CrossRef]

- Monteiro, M.J.; Brouwer, H.D. Intermediate Radiacal Termination as the Mechanism for Retardation in Reversible Addition-Fragmentation Chain Transfer Polymerization. Macromolecules 2001, 34, 349–352. [Google Scholar] [CrossRef]

- Ting, S.R.; Davis, T.P.; Zetterlund, P.B. Retardation in RAFT Polymerization: Does Cross-Termination Occur with Short Radicals Only? Macromolecules 2011, 44, 4187–4193. [Google Scholar] [CrossRef]

- Konkolewicz, D.; Hawkett, B.S.; Gray-Weale, A.; Perrier, S. RAFT polymerization kinetics: How long are the cross-terminatig oligomers? J. Polym. Sci. A Polym. Chem. 2009, 47, 3455–3466. [Google Scholar] [CrossRef]

- Barner-Kowollik, C.; Buback, M.; Charleux, B.; Coote, M.L.; Drache, M.; Fukuda, T.; Goto, A.; Klumperman, B.; Lowe, A.B.; McLeary, J.B.; et al. Mechanism and kinetics of dithiobenzoate-mediated RAFT polymerization. I. The current situation. J. Polym. Sci. A Polym. Chem. 2006, 44, 5809–5831. [Google Scholar] [CrossRef]

- Li, M.; Li, H.; De, P.; Summerlin, B.S. Thermoresponsive Block Copolymer-Protein Conjugates Prepared by Graftng-from via RAFT Polymerization. Macromol. Rapid Commun. 2011, 32, 354–359. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Li, M.; Yu, X.; Bapat, A.P.; Sumerlin, B.S. Block copolymer conjugates prepared by sequentially grafting from proteins via RAFT. Polym. Chem. 2011, 2, 1531–1535. [Google Scholar] [CrossRef]

- Sumerlin, B.S. Proteins as Initiators of Controlled Radical Polymerization: Grafting-from via ATRP and RAFT. ACS Macro Lett. 2012, 1, 141–145. [Google Scholar] [CrossRef]

- Su, X.-L.; He, W.-D.; Li, J.; Li, L.-Y.; Zhang, B.-Y.; Pan, T.-T. RAFT cryopolymerization of N,N-dimethylacrylamide and N-isopropylacrylamide in moderatly frozen aqueous solution. J. Polym. Sci. A Polym. Chem. 2009, 47, 6863–6872. [Google Scholar]

- Su, X.-L.; He, W.-D.; Pan, T.-T.; Ding, Z.-L.; Zhang, Y.-J. RAFT cryopolymerization of acrylamides and acrylates in dioxane at −5 °C. Polymer 2010, 51, 110–114. [Google Scholar]

- Paulus, R.M.; Beer, C.R.; Hoogenboom, R.; Schubert, U.S. High Temperature Initiator-Free RAFT Polymerization of Methyl Methacrylates in a Microwave Reactor. Aust. J. Chem. 2009, 62, 254–259. [Google Scholar] [CrossRef]

- Boyer, C.; Bulmus, V.; Davis, T.P.; Ladmiral, V.; Liu, J.; Perrier, S. Bioapplicatins of RAFT Polymerization. Chem. Rev. 2009, 109, 5402–5436. [Google Scholar] [CrossRef] [PubMed]

- Semsarilar, M.; Perrier, S. ‘Green’ reversible addition-fragmentation chain-transfer (RAFT). Nat. Chem. 2010, 2, 811–820. [Google Scholar] [CrossRef] [PubMed]

- Duffy, C.; Phelan, M.; Zwitterlund, P.; Aldabbagh, F. Reversible addition-fragmentation chain transfer polymerization of alkyl-2-cyanoacrylates: An assessment of livingness. J. Polym. Sci. A Polym. Chem. 2017, 55, 1397–1408. [Google Scholar] [CrossRef]

- Mazieres, S.; Kulai, I.; Geagea, R.; Ladeira, S.; Destarac, M. Mechanistic Understanding of the Divergent Cylcization of 0-Alkynylbenzaldehyde Acetals and Thioacetals Catalyzed by Metal Halides. Chem. Eur. J. 2015, 21, 1726–1734. [Google Scholar] [PubMed]

- Destarac, M.; Gauthier-Gillaizeau, I.; Vuong, C.-T.; Zard, S.Z. Vinylogous Thionothio Compounds for RAFT Polymerization. Macromolecules 2006, 39, 912–914. [Google Scholar] [CrossRef]

- Destarac, M.; Charmot, D.; Franck, X.; Zard, S.Z. Dithiocarbonates as universal reversible addition-fragmentation chain transfer. Macromol. Rapid Commun. 2000, 39, 1035–1039. [Google Scholar] [CrossRef]

- Thang, S.H.; Chong, Y.H.; Mayadunne, R.T.A.; Moad, G.; Rizzardo, E. A novel synthesis of functional diethioesters, diethiocarbamates, xanthates and trithiocarbonates. Tetrahedron Lett. 1999, 40, 2435–2438. [Google Scholar] [CrossRef]

- Esteves, A.C.C.; Hodge, P.; Trindade, T.; Barros-Timmons, A.M. Preparation of nanocomposites by reverssible addition-fragmentation chain transfer polymerization from the surface of quantum dots in mini emulsion. J. Polym. Sci. A Polym. Chem. 2009, 47, 5367–5377. [Google Scholar] [CrossRef]

- Skaff, H.; Emrick, T. Reversible Addition Fragmentation Chain Transfer (RAFT) Polymerization from Unprotected Cadmium Selenide Nanoparticles. Angew. Chem. Int. Ed. 2004, 43, 5383–5386. [Google Scholar] [CrossRef] [PubMed]

- Poetzsch, R.; Fleischmann, S.; Tock, C.; Komber, H.; Voit, B.I. Combining RAFT and Staudinger Ligation: A Potentially New Synthetic Tool for Bioconjugation Formation. Macromolecules 2011, 44, 3260–3269. [Google Scholar] [CrossRef]

- Laus, M.; Papa, R.; Sparnacci, K.; Alberti, A.; Benaglia, M.; Macciantelli, D. Controlled Radical Polymerization of Styrene with Phosphoryl- and (Thiophosphoryl)dithioformates as RAFT Agents. Macromolecules 2001, 34, 7269–7275. [Google Scholar] [CrossRef]