1. Introduction

Additive manufacturing (AM) is one of the most promising areas in the manufacturing of components from prototypes to functional structures with complex geometries and is revolutionizing different important industrial areas such as in aerospace, automotive, semiconductor or biomedical applications [

1,

2,

3,

4,

5,

6,

7,

8,

9]. Additive manufacturing is distinguished from traditional manufacturing techniques, such as casting and machining, by its ability to handle complex shapes with great flexibility and without the typical waste [

7,

8,

10,

11]. Among the different AM techniques, 3D printing based on fused filament fabrication (FFF)—using thermoplastic polymers that require low melting temperature and rapid solidification times—is widely adopted for the simplicity of the method and its relatively low cost and low material wastage [

3,

8,

11,

12,

13]. FFF forms a 3D geometry through the deposition of successive layers of extruded thermoplastic filament, such as acrylonitrile butadiene styrene (ABS), polylactic acid (PLA), polypropylene (PP) or polyethylene (PE). In addition, engineering thermoplastics with improved mechanical performance, such as polyamide (Nylon), polycarbonate (PC), polyetheretherketone (PEEK), polyetherimide (PEI), polyethersulfone (PES) or polyphenylene sulfide (PPS) is also possible [

14]. However, eco-friendly polymeric materials with good physical properties are of major concern for FFF. For example, PLA has great worldwide demand due to versatile applicability in packaging, pharmaceuticals, textiles, automotive, and biomedical and tissue engineering [

15,

16,

17,

18]. It has been widely investigated for biomedical applications due to its biodegradability, bioresorbability and biocompatibility [

15].

The interest in FFF abilities has expanded to include functional finished parts in addition to rapid prototyping. Moreover, the cost of manufacturing small series or unique parts can be significantly reduced [

19]. This has motivated research into the mechanical, electrical, thermal and other properties characterizations and improvements of parts manufactured employing this technology [

8]. Despite the apparent advantage over more traditional methods, FFF printed parts often suffer from poor mechanical characteristics, limiting their broader adaption for end-use, fully functional and load bearing components [

20,

21,

22,

23,

24]. Furthermore, mechanical properties of parts manufactured by conventional FFF 3D printing are inherently poor because of the thermoplastic resin used, although the optimization of processing parameters, such as build orientation, layer thickness or feed rate, has been investigated for improving the mechanical properties of thermoplastic parts in a limited number of studies [

9,

13,

25,

26]. However, regardless of parameter optimization, FFF printed parts still exhibit lower properties compared to those obtained by conventional polymer processing methods such as compression or injection molding [

3]. Additionally, the quality of final fully-formed FFF parts in terms of dimensional accuracy or surface roughness is affected by part intricacy, the corresponding print path, and the differential cool-down and solidification of the individual rasters, among other factors [

27,

28,

29]. Such drawbacks restrict the wide industrial application of 3D printed thermoplastic polymers, leaving prototyping as the primary application [

20]. Hence, it is very necessary to understand the shortcomings of the FFF process for its better application in modern industries.

3D printing of polymer composites with enhanced mechanical properties solves the previous limitations by combining the matrix and reinforcements to achieve a system with more useful structural or functional properties non-attainable by any of the constituent alone [

8,

30]. Incorporation of particles, fibers or nanomaterial reinforcements into polymers permits the fabrication of polymer matrix composites that are characterized by high performance and excellent functionality [

7,

8,

31]. Various reinforcement, such as short fibers, including chopped carbon or glass fibers, have been used in a limited number of studies with a moderate improvement of mechanical properties [

10,

24,

32,

33,

34,

35,

36,

37]. In most studies, short fibers were embedded in ABS or Nylon thermoplastic filaments, prior to being loaded into the printer. The possibility of employing continuous fiber reinforced thermoplastic composites may lead to products with much higher mechanical performance, which are potentially useful for advanced applications [

38,

39]. However, their processing is not commonplace, and a specially designed printer is required [

3,

20,

22,

30,

40].

The allure of the recent introduction of nanotechnology into this innovative field is due to the remarkable improvements and diversifications in properties of the resulting 3D printed materials, exhibiting optimized properties and multifunctionality. In particular, there is increasing interest in the development of high-performance composites suitable for 3D printing, achieved via the introduction of nanomaterials with unique properties such as nanotubes and graphene and its derivatives in the polymer matrix. Graphene’s excellent mechanical, electrical and thermal properties make it an attractive candidate for the reinforcement of several polymers [

41]. Graphene’s addition to polymer matrices has resulted in composites exhibiting superior mechanical strength while retaining its flexibility, as well as tailorable thermal and electrical conductivity because of the graphene network in the matrix [

15,

16,

17,

18]. However, PLA-graphene composite blends are currently being used for the fabrication of 3D-printed scaffolds for tissue engineering [

16]. Although biocompatibility of graphene-reinforced PLA has been proven in previous studies, its potential application in load-bearing structures and the resultant performance under different loading conditions need to be evaluated [

18,

42]. Recently, a few studies have reported the successful development of graphene-based reinforced polymer composites for 3D printing [

43,

44,

45]. However, in composites, the main challenge is to understand how to transfer the properties of graphene from the nanoscale to the macroscale. Although research shows particularly promising improvement in thermal and electrical conductivities of graphene-based nanocomposites [

44,

45,

46,

47], the primary goal of this research is to explore the initial steps toward improving the mechanical performance of 3D printed PLA-based nanocomposites that include graphene nanoplatelets (GNPs). The addition of graphene nanoplatelets to polymers is under investigation as a promising method to improve the mechanical and thermal properties of these materials. However, previous findings showed that the addition of other types of particles to PLA-based composites caused a decrease in the mechanical properties of the polymer composite used in 3D printing [

48]. In addition, among the existing literature on mechanical properties of 3D printed PLA composites, there is a lack of study on their interlaminar bonding performance [

37,

38,

39,

49]. The interface bounding quality between layers and wires significantly influences the microstructure and mechanical properties of the resulting parts [

39]. Moreover, further research is required to determine the quality of 3D printed composites parts as a function of different process parameters (build orientation, layer thickness or type of reinforcement) in terms of dimensional accuracy or surface roughness since the literature on the dimensional and surface texture characterization of 3D printed parts processed by the FFF technique is somewhat scarce [

27].

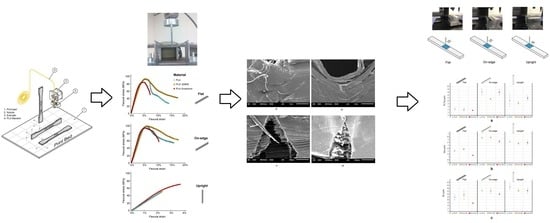

In this study, commercially available polylactic acid (PLA), an enhanced PLA-based polymer (PLA 3D850) and graphene nanoplatelet reinforced PLA composite (PLA-Graphene) filaments were used to manufacture different samples by the FFF technique using a low-cost desktop 3D printer. The mechanical properties, in terms of tensile and three-point bending performance, are evaluated. In addition, the interlaminar bonding and impact performance of the 3D printed samples are also studied. The effect of the graphene reinforcement and build orientation are analyzed. A comparison of the mechanical performance, dimensional accuracy and surface texture between virgin PLA and reinforced PLA samples is also conducted. Finally, SEM images of failure samples are evaluated to determine the effects of the process parameters on failure modes.

The rest of the paper is organized as follows. First, the experimental methodology carried out in this study is briefly summarized with particular emphasis on specimen preparation, the 3D printing process and the experimental set-up. Thereafter, the key results of the investigation are summarized, and the effects of the different process parameters on the mechanical performance, dimensional accuracy and texture are highlighted. Finally, conclusions and extensions of this work are outlined.

4. Conclusions

The mechanical performance, dimensional accuracy and surface roughness analysis of 3D printed PLA-based and graphene nanoplatelets (GNPs) reinforced composites manufactured by FFF technique have been analyzed. The effect of build orientation and graphene reinforcement were studied in particular. Tensile, three-point bending, Charpy impact and interlaminar shear strength tests were carried out to determine the mechanical response of the 3D printed specimens following ASTM standard recommendations. SEM images of ILSS failure samples were evaluated to determine the effects of GNPs on bonding performance.

It has been shown that the effect of build orientation was of particular significance on the mechanical performance of PLA-based materials. On-edge and flat orientations showed the highest values for maximum tensile and flexural strengths and stiffness, while upright orientation resulted in the lowest ones. There were no significant differences between PLA and PLA3D850 in terms of tensile and flexural behavior. Furthermore, PLA-Graphene composite samples showed the best performance in terms of tensile and flexural stress and stiffness, except in the case of on-edge orientation. GNPs offered higher stiffness with respect to PLA matrix, preventing the shear strain. More specifically, PLA-Graphene composite showed a significant improvement of the tensile behavior over the other two materials in the case of upright orientation. However, the addition of GNPs tended to reduce the impact strength of the PLA composite samples. Finally, PLA-Graphene composite samples showed the highest interlaminar shear strength. These results were in accordance with the enhanced interlaminar adhesion and performance showed by the PLA-Graphene samples under tensile and flexural loading.

Moreover, the addition of graphene nanoplatelets did not affect, in general terms, the dimensional accuracy of the PLA-Graphene composite specimens. They showed, in overall terms, the best dimensional accuracy in Z-axis due to enhanced interlaminar performance. Finally, PLA-Graphene specimens showed, in overall terms, the best performance in terms of surface texture, particularly when parts were printed in flat and on-edge orientations.

The results have shown that it is still a challenge to increase the mechanical performance of 3D printed reinforced composite materials with respect to conventional polymer processing methods such as compression or injection molding. A compaction stage after the deposition of the filament would be desirable to reduce porosity. Nevertheless, the properties obtained by 3D printed reinforced composites by FFF are, in general terms, higher than the usual 3D FFF thermoplastics.

In conclusion, using FFF to fabricate 3D printed composites with much higher mechanical performance has become a cutting-edge and interdisciplinary research topic in the last few years. It seems to be a very promising technology with potential for future development. It is a relatively new technique and there is a lack of experimental data on the mechanical performance of structures manufactured by this process, underscoring the need for further research to improve our understanding of the mechanical behavior of 3D printed composites.