A Review of Wet Compounding of Cellulose Nanocomposites

Abstract

:1. Introduction

2. Discussion

2.1. Cellulose Nanomaterials

2.2. Wet Compounding of Clay Nanocomposites

2.3. Wet Extrusion Compounding of CNs

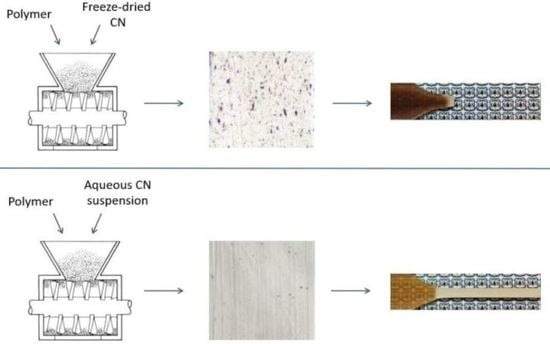

2.3.1. Compounding of CN Suspensions

| Polymer | CN Type, Feed Conc., Final Conc. | Additive, Final Conc. | Compounding | Results | Reference |

|---|---|---|---|---|---|

| PLA | CNCs from MCC MFC by refining/cryocrushing, 4%, 5% | Polyethylene glycol (PEG), 5% | Polymer fed in 1st zone; CNC or MFC suspension fed at 4th zone by peristaltic pump; atmospheric venting at 7th and 8th zones and vacuum venting at 10th zone (of 11 zones); 100 rpm; 165–185 °C; 4 kg/h | No significant improvement in mechanical properties compared to PLA, which was attributed to non-uniform dispersion | Mathew et al. 2006 [58] |

| PLA Maleated PLA | CNCs from MCC 1 in DMAc 2 and LiCl 17%, 5% | Polyethylene glycol (PEG), 15% | Polymer fed in 1st zone; CNC suspension fed in 4th zone (of 11); 25 mm screw, 150 rpm, 5 kg/h, 170–185 °C; atmospheric and vacuum venting | Nanoscale dispersion with PEG; DMAc deteriorated PLA properties but CNCs improved DMAc-PLA controls | Oksman et al. 2006 [12] |

| PLA Polyvinyl alcohol (PVOH) | CNCs, ~3–4% 3 (in a 6:1 PVOH:CNC (aq) suspension), 5% | NaOH added to CNC-PVOH suspension, (0.25 mol/L of suspension) | CNC suspension fed by peristaltic pump downstream from main feed throat; 25 mm screw; 150 rpm, 4 kg/h, 170–200 °C; atmospheric and vacuum venting | PLA and PVOH were immiscible; CNCs were primarily found with PVOH; Increases in properties were attributed to reinforcing the PVOH phase | Bondeson and Oksman 2007 [55] |

| Cellulose Acetate Butyrate (CAB) | CNCs, 3.9%, 5% | Triethyl citrate (TEC), 15% | Polymer fed in main feed throat; CNC in water and ethanol with TEC fed downstream into melt; 25 mm screw; 150 rpm, 4.2 kg/h, 140–170 °C; atmospheric and vacuum venting | CNCs were dispersed in CAB; operating temperature of the nanocomposites increased from 100 to 140 °C; composites transparent | Bondeson et al. 2007 [59] |

| LDPE | Carboxylated CNCs neutralized with NaOH, N/A, 4 2.5% | Cationic surfactant, N/A 4 | CNC suspension fed into melt; sealing rings used; 180–200 °C, 5 kg/h, 34 mm screw | Slurry injection reduced CNC aggregates, especially for functionalized polymers; tensile strength of functionalized LDPE increased by 38% with surfactant | Stoeffler et al. 2013 [9] |

| PP | |||||

| LDPE w/5–10% polar groups | |||||

| PP w/0–1% polar groups | |||||

| PLA | CNF mechanically fibrillated from banana waste, 1.3%, 1% | Glycerol triacetate (GTA), 20% | CNF suspension (61% acetone/25% GTA/12% water) fed into main feed throat (with PLA pellets) using peristaltic pump; 3 kg/h total (removed 1.7–1.8 kg/h vapor), 300 rpm; 170–200 °C; atmospheric and vacuum venting | CNFs improved work of fracture, nearly doubling the effect of plasticizer | Herrera et al. 2015 [54] |

| PLA | Sulfated CNCs (sodium form), 2.6%, 1% | Triethyl citrate (TEC), 20% | CNC suspension (52% TEC, 22.7% water, 22.7% ethanol) fed into main feed throat (with PLA pellets) using peristaltic pump; 3 kg/h total, 300 rpm; 170–200 °C; atmospheric and vacuum venting | CNCs enhanced mechanical properties of plasticized PLA; mostly achieved nanoscale dispersion with some agglomerates; fast cooling yielded more transparent composites with higher elongation at break | Herrera et al. 2016 [53] |

| Polyamide 6 (PA6) | Sulfated CNCs (sodium form), 1.7–11%, 0.5–3.5% | - | CNC suspension injected into melt, which was sealed with sealing rings and reverse knead elements; water was maintained as liquid by pressuring with N2 to exploit cryoscopic effect of PA6, resulting in reducing temps in middle of extruder by 30 °C; vacuum venting at end | Nanoscale dispersion of CNCs, which acted as nucleation fillers for microcellular foaming; CNCs increased cell density and reduced cell size and improved mechanical properties of foamed composites. | Peng et al. 2016 [6] |

| Polyethylene (PE) Maleated PE | CNF mechanically fibrillated from Oil palm mesocarp fiber, 0.2%, 0.5-5% | - | Liquid fed at main feed throat with polymers; 80/160/160/160 °C; 50 rpm; compared to batch mixing; venting downstream | Improved tensile and flexural moduli and strength values compared to neat polymer and batch method; maximum properties around 3% CNF | Yasim-Anuar et al. 2020 [60] |

| Polymer | CN Type, Initial Conc., Final Conc. | Additive, Final Conc. | Mixing and Compounding | Results | Reference |

|---|---|---|---|---|---|

| Potato starch (powder) | Mechanical CNFs, 12%, 5–20% | D-sorbitol, 30% (of starch); stearic acid, 1% (of starch) | All components mixed in blender, giving “powdery state”; fed in main feed throat; 80–110 °C; 200 rpm; venting at zones 2 and 4 (out of 7) | CNF improved mechanical properties and favorably affected moisture uptake; transparency reduced but good even at 20%; some aggregation of CNFs | Hietala et al. 2013 [61] |

| PP (powder) MAPP | Mechanical CNFs 20–25%, 30% | Cationic polymer with primary amino group (CPPA), 6% or 9% | PP, MAPP, and CPPA mixed in food blender, then fed into extruder; 110–180 °C; 200 rpm; 200 g/h; they compared this pre-mixing method with extrusion fibrillation case | Significant improvement of tensile properties compared to PP but was not as good as the case in which they fibrillated the cellulose by extrusion | Suzuki et al. 2017 [50] |

| PCL (powder) PMMA (poly(methyl methacrylate)) nanoparticles | Enzymatic/mechanical CNFs, 1.6%, 10% or 20% | - | Polymers and CNF mixed and dried to 50% solids; used a microcompounder; 30 rpm for 5 min (feeding) and 100 rpm for 10 min; 120 °C | Wet feeding alone was better than dry feeding but using PMMA particles had bigger impact due to improved dispersion | Lo Re et al. 2018 [62] |

| PCL (powder) | CNF and MFC, 1.5% (CNF) and 2.4% or 10% (MFC), 3–5% (CNF) and 3-20% (MFC) | - | Compared coarse pulp, CNF and MFC; manually mix PCL and cellulose; used a microcompounder; 30 rpm for 5 min (feeding) and 100 rpm for 10 min; 120 °C; initial water contents 0–76% | Wet feeding gave improved mechanical properties for pulp; pulp performed as well as CNF; wet feeding preserves fiber length; low aspect ratio MFC did not improve mechanical properties much; | Lo Re and Sessini 2018 [64] |

| PCL (powder) Copolymer of 2-(dimethylamino)ethyl methacrylate and 2-hydroxy methacrylate | TEMPO 1—oxidized CNFs, 1%, ~10% | benzoyl peroxide (Luperox A75), 0.05–0.1% | Used a waterborne reactive nanoparticle compatibilizer to modify CNF first, then all components mixed and dried to 50% solids; used a microcompounder; 30 rpm for 5 min (feeding) and 100 rpm for 10 min; 140 °C | Their synthesized compatibilizer improved dispersion and properties; tensile and bending DMA showed significant increase in strength and stiffness | Kaldéus et al. 2019 [63] |

2.3.2. Compounding of Fibrillated Cellulose

2.3.3. Water Effects on Molecular Weight and Crystal Structure

2.3.4. Water Effects on Additives

2.4. Wet Batch Compounding of CNs

3. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hansen, F.; Brun, V.; Keller, E.; Nieh, W.; Wegner, T.; Meador, M.; Friedersdorf, L. Cellulose Nanomaterials—A Path towards Commercialization Workshop Report; The U.S. Department of Agriculture (USDA) in collaboration with the National Nanotechnology Initiative (NNI): Washington, DC, USA, 2014; p. 44.

- Eyley, S.; Thielemans, W. Surface modification of cellulose nanocrystals. Nanoscale 2014, 6, 7764–7779. [Google Scholar] [CrossRef] [Green Version]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S.; et al. Review: Current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1–33. [Google Scholar] [CrossRef] [Green Version]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef]

- Habibi, Y. Key advances in the chemical modification of nanocelluloses. Chem. Soc. Rev. 2014, 43, 1519–1542. [Google Scholar] [CrossRef]

- Peng, J.; Walsh, P.J.; Sabo, R.C.; Turng, L.-S.; Clemons, C.M. Water-assisted compounding of cellulose nanocrystals into polyamide 6 for use as a nucleating agent for microcellular foaming. Polymer 2016, 84, 158–166. [Google Scholar] [CrossRef] [Green Version]

- Sapkota, J.; Natterodt, J.C.; Shirole, A.; Foster, E.J.; Weder, C. Fabrication and properties of polyethylene/cellulose nanocrystal composites. Macromol. Mater. Eng. 2017, 302, 1600300. [Google Scholar] [CrossRef]

- Clemons, C. Comparison of Compounding Approaches for Wood-Derived Cellulose Nanocrystals and Polyamide 6. In Society of Plastics Engineers; ANTEC 2015: Orlando, FL, USA, 2015; pp. 430–434. ISBN 978-0-9850112-7-7. [Google Scholar]

- Stoeffler, K.; Leung, A.C.W.; Legros, N.; Luong, J.H.T. Polyolefin/NCC Composites Processed by Water-Assisted Extrusion. In Proceedings of the 2013 TAPPI International Conference on Nanotechnology for Renewable Materials, Stockholm, Sweden, 24–27 June 2013. [Google Scholar]

- Sabo, R.; Stark, N.; Wei, L.; Matuana, L. Wet Compounding of Cellulose Nanocrystals into Polylactic Acid for Packaging Applications. In Proceedings of the ANTEC 2019-The Plastics Conference, Detroit, MI, USA, 18–20 March 2019. [Google Scholar]

- Sabo, R.C.; Nabinejad, O.; Stark, N.M.; Lebow, P.; Karkhanis, S.; Matuana, L.M. Novel Method of Compounding Cellulose Nanocrystal Suspensions into Polylactic Acid and Polyvinyl Acetate Blends. In Proceedings of the ANTEC, San Antonio, TX, USA, 30 March–2 April 2020. [Google Scholar]

- Oksman, K.; Mathew, A.P.; Bondeson, D.; Kvien, I. Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos. Sci. Technol. 2006, 66, 2776–2784. [Google Scholar] [CrossRef]

- Mapleston, P. Compounders with a Real Difference. In Compounding World; Applied Market Information: Bristol, UK, 2019; pp. 79–90. [Google Scholar]

- Touchaleaume, F.; Soulestin, J.; Sclavons, M.; Devaux, J.; Lacrampe, M.F.; Krawczak, P. One-step water-assisted melt-compounding of polyamide 6/pristine clay nanocomposites: An efficient way to prevent matrix degradation. Polym. Degrad. Stab. 2011, 96, 1890–1900. [Google Scholar] [CrossRef]

- Wevers, M.G.M.; Pijpers, T.F.J.; Mathot, V.B.F. The way to measure quantitatively full dissolution and crystallization of polyamides in water up to 200 °C and above by DSC. Thermochim. Acta 2007, 453, 67–71. [Google Scholar] [CrossRef]

- Klemm, D.; Kramer, F.; Moritz, S.; Lindström, T.; Ankerfors, M.; Gray, D.; Dorris, A. Nanocelluloses: A New Family of Nature-Based Materials. Angew. Chem. Int. Ed. 2011, 50, 5438–5466. [Google Scholar] [CrossRef]

- Siró, I.; Plackett, D. Microfibrillated cellulose and new nanocomposite materials: A review. Cellulose 2010, 17, 459–494. [Google Scholar] [CrossRef]

- Samir, M.A.S.A.; Alloin, A.F.; Dufresne, A. Review of Recent Research into Cellulosic Whiskers, Their Properties and Their Application in Nanocomposite Field. Biomacromolecules 2005, 6, 612–626. [Google Scholar] [CrossRef] [PubMed]

- Habibi, Y.; Lucia, L.A.; Rojas, O.J. Cellulose nanocrystals: Chemistry, self-assembly, and applications. Chem. Rev. 2010, 110, 3479–3500. [Google Scholar] [CrossRef] [PubMed]

- Kargarzadeh, H.; Mariano, M.; Gopakumar, D.; Ahmad, I.; Thomas, S.; Dufresne, A.; Huang, J.; Lin, N. Advances in cellulose nanomaterials. Cellulose 2018, 25, 2151–2189. [Google Scholar] [CrossRef]

- Qing, Y.; Sabo, R.; Zhu, J.Y.; Agarwal, U.; Cai, Z.; Wu, Y. A comparative study of cellulose nanofibrils disintegrated via multiple processing approaches. Carbohydr. Polym. 2013, 97, 226–234. [Google Scholar] [CrossRef]

- Miller, J. Nanocellulose Producers, Products, and Applications: Guide for End Users; TAPPI Press: Peachtree Corners, GA, USA, 2017; pp. 1–175. [Google Scholar]

- Herrick, F.W.; Casebier, R.L.; Hamilton, J.K.; Sanberg, K.R. Microfibrillated cellulose: Morphology and accessibility. J. Appl. Polym. Sci. 1983, 37, 797–813. [Google Scholar]

- Turbak, A.F.; Snyder, F.W.; Sandberg, K.R. Microfibrillated cellulose, a new cellulose product: Properties, uses, and commercial potential. J. Appl. Polym. Sci. 1983, 37, 815–827. [Google Scholar]

- Pääkkö, M.; Ankerfors, M.; Kosonen, H.; Nykänen, A.; Ahola, S.; Österberg, M.; Ruokolainen, J.; Laine, J.; Larsson, P.T.; Ikkala, O.; et al. Enzymatic hydrolysis combined with mechanical shearing and high-pressure homogenization for nanoscle cellulose fibrils and strong gels. Biomacromolecules 2007, 8, 1934–1941. [Google Scholar] [CrossRef]

- Dimic-Misic, K.; Gane, P.A.C.; Paltakari, J. Micro- and nanofibrillated cellulose as a rheology modifier additive in CMC-containing pigment-coating formulations. Ind. Eng. Chem. Res. 2013, 52, 16066–16083. [Google Scholar] [CrossRef]

- Shafiei-Sabet, S.; Martinez, M.; Olson, J. Shear rheology of micro-fibrillar cellulose aqueous suspensions. Cellulose 2016, 23, 2943–2953. [Google Scholar] [CrossRef]

- Klemm, D.; Cranston, E.D.; Fischer, D.; Gama, M.; Kedzior, S.A.; Kralisch, D.; Kramer, F.; Kondo, T.; Lindström, T.; Nietzsche, S.; et al. Nanocellulose as a natural source for groundbreaking applications in materials science: Today’s state. Mater. Today 2018, 21, 720–748. [Google Scholar] [CrossRef] [Green Version]

- Samyn, P.; Taheri, H. Rheology of fibrillated cellulose suspensions after surface modification by organic nanoparticle deposits. J. Mater. Sci. 2016, 51, 9830–9848. [Google Scholar] [CrossRef]

- Sinquefield, S.; Ciesielski, P.N.; Li, K.; Gardner, D.J.; Ozcan, S. Nanocellulose dewatering and drying: Current state and future perspectives. ACS Sustain. Chem. Eng. 2020, 8, 9601–9615. [Google Scholar] [CrossRef]

- Karger-Kocsis, J.; Kmetty, Á.; Lendvai, L.; Drakopoulos, S.; Bárány, T. Water-Assisted Production of Thermoplastic Nanocomposites: A Review. Materials 2014, 8, 72–95. [Google Scholar] [CrossRef] [Green Version]

- Rousseaux, D.D.J.; Sallem-Idrissi, N.; Baudouin, A.-C.; Devaux, J.; Godard, P.; Marchand-Brynaert, J.; Sclavons, M. Water-assisted extrusion of polypropylene/clay nanocomposites: A comprehensive study. Polymer 2011, 52, 443–451. [Google Scholar] [CrossRef]

- Korbee, R.; van Geenen, A. Process for the Preparation of a Polyamide Nanocomposite Composition. International Patent Application No. WO 99/29767, 17 June 1999. [Google Scholar]

- Fedullo, N.; Sclavons, M.; Bailly, C.; Lefebvre, J.-M.; Devaux, J. Nanocomposites from untreated clay: A myth? Macromol. Symp. 2006, 233, 235–245. [Google Scholar] [CrossRef]

- Hasegawa, N.; Okamoto, H.; Kato, M.; Usuki, A.; Sato, N. Nylon 6/Na—Montmorillonite nanocomposites prepared by compounding Nylon 6 with Na—Montmorillonite slurry. Polymer 2003, 44, 2933–2937. [Google Scholar] [CrossRef]

- Kato, M.; Matsushita, M.; Fukumori, K. Development of a new production method for a polypropylene-clay nanocomposite. Polym. Eng. Sci. 2004, 44, 1205–1211. [Google Scholar] [CrossRef]

- Shahabadi, S.I.S.; Garmabi, H. Response surface analysis of structural, mechanical, and permeability properties of polyethylene/Na+-montmorillonite composites, prepared by slurry-fed melt intercalation. Express Polym. Lett. 2012, 6, 657–671. [Google Scholar] [CrossRef]

- Suzuki, K.; Okumura, H.; Kitagawa, K.; Sato, S.; Nakagaito, A.N.; Yano, H. Development of continuous process enabling nanofibrillation of pulp and melt compounding. Cellulose 2013, 20, 201–210. [Google Scholar] [CrossRef]

- Suzuki, K.; Sato, A.; Okumura, H.; Hashimoto, T.; Nakagaito, A.N.; Yano, H. Novel high-strength, micro fibrillated cellulose-reinforced polypropylene composites using a cationic polymer as compatibilizer. Cellulose 2014, 21, 507–518. [Google Scholar] [CrossRef]

- Suzuki, K.; Homma, Y.; Igarashi, Y.; Okumura, H.; Semba, T.; Nakatsubo, F.; Yano, H. Investigation of the mechanism and effectiveness of cationic polymer as a compatibilizer in microfibrillated cellulose-reinforced polyolefins. Cellulose 2016, 23, 623–635. [Google Scholar] [CrossRef]

- Yano, H.; Obi, N.; Usuki, A. Toward the Applications of CNFs Materials for Automotive Parts. In Proceedings of the 2018 TAPPI International Conference on Nanotechnology for Renewable Materials, Madison, WI, USA, 13 June 2018. [Google Scholar]

- Lo Re, G.; Spinella, S.; Boujemaoui, A.; Vilaseca, F.; Larsson, P.T.; Adås, F.; Berglund, L.A. Poly (ε-caprolactone) Biocomposites Based on Acetylated Cellulose Fibers and Wet Compounding for Improved Mechanical Performance. ACS Sustain. Chem. Eng. 2018, 6, 6753–6760. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Okada, K.; Sodenaga, M.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Yano, H. Effect of surface modification on the dispersion, rheological behavior, crystallization kinetics, and foaming ability of polypropylene/cellulose nanofiber nanocomposites. Compos. Sci. Technol. 2018, 168, 412–419. [Google Scholar] [CrossRef]

- Sato, A.; Kabusaki, D.; Okumura, H.; Nakatani, T.; Nakatsubo, F.; Yano, H. Surface modification of cellulose nanofibers with alkenyl succinic anhydride for high-density polyethylene reinforcement. Compos. Part A Appl. Sci. Manuf. 2016, 83, 72–79. [Google Scholar] [CrossRef]

- Yano, H.; Sato, A.; Yoshimura, T.; Igarashi, Y.; Kabusaki, D.; Nakatsubo, F.; Okumura, H.; Semba, T.; Kitagawa, K.; Kataoka, H. Method for Producing Resin Composition Comprising Modified Microfibrillated Plant Fibers, and Same Resin Composition. U.S. Patent 9,512,304 B2, 6 December 2016. [Google Scholar]

- Yano, H.; Omura, H.; Honma, Y.; Okumura, H.; Sano, H.; Nakatsubo, F. Designing cellulose nanofiber surface for high density polyethylene reinforcement. Cellulose 2018, 25, 3351–3362. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Okada, K.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Yano, H. Effect of cellulose nanofiber (CNF) surface treatment on cellular structures and mechanical properties of polypropylene/CNF nanocomposite foams via core-back foam injection molding. Polymers 2019, 11, 249. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Wang, L.; Ando, M.; Kubota, M.; Ishihara, S.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Sato, A.; Yano, H. Effects of hydrophobic-modified cellulose nanofibers (CNFs) on cell morphology and mechanical properties of high void fraction polypropylene nanocomposite foams. Compos. Part A Appl. Sci. Manuf. 2017, 98, 166–173. [Google Scholar] [CrossRef]

- Igarashi, Y.; Sato, A.; Okumura, H.; Nakatsubo, F.; Yano, H. Manufacturing process centered on dry-pulp direct kneading method opens a door for commercialization of cellulose nanofiber reinforced composites. Chem. Eng. J. 2018, 354, 563–568. [Google Scholar] [CrossRef]

- Suzuki, K.; Homma, Y.; Igarashi, Y.; Okumura, H.; Yano, H. Effect of preparation process of microfibrillated cellulose-reinforced polypropylene upon dispersion and mechanical properties. Cellulose 2017, 24, 3789–3801. [Google Scholar] [CrossRef]

- Wang, L.; Hikima, Y.; Ohshima, M.; Sekiguchi, T.; Yano, H. Evolution of cellular morphologies and crystalline structures in high-expansion isotactic polypropylene/cellulose nanofiber nanocomposite foams. RSC Adv. 2018, 8, 15405–15416. [Google Scholar] [CrossRef] [Green Version]

- Sato, A.; Yoshimura, T.; Kabusaki, D.; Okumura, H.; Homma, Y.; Nakatsubo, F.; Yano, H. Multi-functional effect of alkenyl-succinic-anhydride-modified microfibrillated celluloses as reinforcement and a dispersant of CaCO3 in high-density polyethylene. Cellulose 2019, 26, 6641–6651. [Google Scholar] [CrossRef]

- Herrera, N.V.; Salaberria, A.M.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid nanocomposite films with cellulose and chitin nanocrystals prepared using extrusion and compression molding with two cooling rates: Effects on mechanical, thermal and optical properties. Compos. Part A Appl. Sci. Manuf. 2016, 83, 89–97. [Google Scholar] [CrossRef] [Green Version]

- Herrera, N.V.; Mathew, A.P.; Oksman, K. Plasticized polylactic acid/cellulose nanocomposites prepared using melt-extrusion and liquid feeding: Mechanical, thermal and optical properties. Compos. Sci. Technol. 2015, 106, 149–155. [Google Scholar] [CrossRef]

- Bondeson, D.; Oksman, K. Polylactic acid/cellulose whisker nanocomposites modified by polyvinyl alcohol. Compos. Part A Appl. Sci. Manuf. 2007, 38, 2486–2492. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Sain, M. Novel bionanocomposites: Processing, properties and potential applications. Plast. Rubber Compos. 2009, 38, 396–405. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P. Melt Compounding Process of Cellulose Nanocomposites. In Handbook of Green Materials: 2 Bionanocomposites: Processing, Characterization and Properties; World Scientific: Singapore, 2014; pp. 53–68. [Google Scholar]

- Mathew, A.P.; Chakraborty, A.; Oksman, K.; Sain, M. The Structure and Mechanical Properties of Cellulose Nanocomposites Prepared by Twin Screw Extrusion. In Cellulose Nanocomposites: Processing, Characterization, and Properties; Oksman, K., Sain, M., Eds.; American Chemical Society: Washington, DC, USA, 2006. [Google Scholar]

- Bondeson, D.; Syre, P.; Niska, K.O. All cellulose nanocomposites produced by extrusion. J. Biobased Mater. Bioenergy 2007, 1, 367–371. [Google Scholar] [CrossRef]

- Yasim-Anuar, T.A.T.; Ariffin, H.; Norrrahim, M.N.F.; Hassan, M.A.; Andou, Y.; Tsukegi, T.; Nishida, H. Well-Dispersed Cellulose Nanofiber in Low Density Polyethylene Nanocomposite by Liquid-Assisted Extrusion. Polymers 2020, 12, 927. [Google Scholar] [CrossRef] [Green Version]

- Hietala, M.; Mathew, A.P.; Oksman, K. Bionanocomposites of thermoplastic starch and cellulose nanofibers manufactured using twin-screw extrusion. Eur. Polym. J. 2013, 49, 950–956. [Google Scholar] [CrossRef]

- Lo Re, G.; Engström, J.; Wu, Q.; Malmström, E.; Gedde, U.W.; Olsson, R.T.; Berglund, L. Improved cellulose nanofibril dispersion in melt-processed polycaprolactone nanocomposites by a latex-mediated interphase and wet feeding as LDPE alternative. ACS Appl. Nano Mater. 2018, 1, 2669–2677. [Google Scholar] [CrossRef]

- Kaldéus, T.; Träger, A.; Berglund, L.A.; Malmström, E.; Re, G.L. Molecular Engineering of the Cellulose-Poly (Caprolactone) Bio-Nanocomposite Interface by Reactive Amphiphilic Copolymer Nanoparticles. ACS Nano 2019, 13, 6409–6420. [Google Scholar] [CrossRef]

- Lo Re, G.; Sessini, V. Wet Feeding Approach for Cellulosic Materials/PCL Biocomposites. In Biomass Extrusion and Reaction Technologies: Principles to Practices and Future Potential; ACS Publications: Washington, DC, USA, 2018; pp. 209–226. [Google Scholar]

- Soulestin, J.; Quiévy, N.; Sclavons, M.; Devaux, J. Polyolefins—Biofibre composites: A new way for an industrial production. Polym. Eng. Sci. 2007, 47, 467–476. [Google Scholar] [CrossRef]

- Beaugrand, J.; Berzin, F. Lignocellulosic fiber reinforced composites: Influence of compounding conditions on defibrization and mechanical properties. J. Appl. Polym. Sci. 2013, 128, 1227–1238. [Google Scholar] [CrossRef]

- Pracella, M.; Haque, M.M.-U.; Puglia, D. Morphology and properties tuning of PLA/cellulose nanocrystals bio-nanocomposites by means of reactive functionalization and blending with PVAc. Polymer 2014, 55, 3720–3728. [Google Scholar] [CrossRef]

- Clemons, C.; Reiner, R. Preparation of Cellulose Nanocrystal-Polypropylene Masterbatches by Water-Assisted Thermokinetic Mixing. In Proceedings of the Presented at the Society of Plastics Engineers’ ANTEC® 2020: The Virtual Edition, San Antonio, TX, USA, 30 March–2 April 2020. [Google Scholar]

- Lafia-Araga, R.A.; Sabo, R.C.; Stark, N.M.; Matuana, L.M. Water Based Esterification of Cellulose Nanofibril for Compounding with PLA. In Proceedings of the 72nd Forest Products Society International Convention, Madison, WI, USA, 11–14 June 2018. [Google Scholar]

- Gopakumar, T.G.; Pagé, D.J.Y.S. Compounding of nanocomposites by thermokinetic mixing. J. Appl. Polym. Sci. 2005, 96, 1557–1563. [Google Scholar] [CrossRef]

- Lei, Y.; Wu, Q.; Clemons, C.M. Preparation and properties of recycled HDPE/clay hybrids. J. Appl. Polym. Sci. 2007, 103, 3056–3063. [Google Scholar] [CrossRef] [Green Version]

- Özen, İ.; İnceoǧlu, F.; Acatay, K.; Menceloǧlu, Y.Z. Comparison of melt extrusion and thermokinetic mixing methods in poly(ethylene terephthalate)/montmorillonite nanocomposites. Polym. Eng. Sci. 2012, 52, 1537–1547. [Google Scholar] [CrossRef]

- Gopakumar, T.G.; Pagé, D.J.Y.S. Polypropylene/graphite nanocomposites by thermo-kinetic mixing. Polym. Eng. Sci. 2004, 44, 1162–1169. [Google Scholar] [CrossRef]

- Gonzalez, C.; Clemons, C.M.; Meyers, G.E.; Harten, T.M. Effects of Several Ingredient Variables on Mechanical Properties of Wood Fiber-Polyolefin Composites Blended in a Thermokinetic Mixer. In Proceedings of the Materials Interactions Relevant to Recycling of Wood-Based Materials: Materials Research Society Symposium, San Francisco, CA, USA, 27–29 April 1992; p. 127. [Google Scholar]

- English, B.; Clemons, C.M.; Stark, N.M.; Schneider, J.P. Waste-Wood-Derived Fillers for Plastics; General Technical Report FPL-GTR-91; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1996; pp. 1–15.

- Javadi, A.; Srithep, Y.; Lee, J.; Pilla, S.; Clemons, C.; Gong, S.; Turng, L.-S. Processing and characterization of solid and microcellular PHBV/PBAT blend and its RWF/nanoclay composites. Compos. Part A Appl. Sci. Manuf. 2010, 41, 982–990. [Google Scholar] [CrossRef]

- Jacobson, R.E.; Rowell, R.M.; Caulfield, D.F.; Sanadi, A.R. Property Improvement Effects of Agricultural Fibers and Wastes as Reinforcing Fillers in Polypropylene-Based Composites. In Proceedings of the Wood Fiber Plastics Composites Conference, Madison, WI, USA, 1–3 May 1995; pp. 211–219. [Google Scholar]

- Clemons, C.; Sanadi, A.R. Instrumented impact testing of kenaf fiber reinforced polypropylene composites: Effects of temperature and composition. J. Reinf. Plast. Compos. 2007, 26, 1587–1602. [Google Scholar] [CrossRef]

- Clemons, C.M.; Meyers, G.E.; Saeman, J.F.; Ermer, D.S. Waste-Newspaper-Polypropylene Thermoplastic Composites: Research- and Plant-Scale Studies of Commercial Feasibility. In Proceedings of the Wastepaper V, Chicago, IL, USA, 27–30 March 1994; pp. 1–20. [Google Scholar]

- Clemons, C.M. Unpublished Data.

- Nguyen, Q.T.; Baird, D.G. An improved technique for exfoliating and dispersing nanoclay particles into polymer matrices using supercritical carbon dioxide. Polymer 2007, 48, 6923–6933. [Google Scholar] [CrossRef]

- Ellingham, T.; Duddleston, L.; Turng, L.-S. Sub-critical gas-assisted processing using CO2 foaming to enhance the exfoliation of graphene in polypropylene + graphene nanocomposites. Polymer 2017, 117, 132–139. [Google Scholar] [CrossRef]

- Százdi, L.; Ábrányi, Á.; Pukánszky, B.; Vancso, J.G.; Pukánszky, B. Morphology characterization of PP/clay nanocomposites across the length scales of the structural architecture. Macromol. Mater. Eng. 2006, 291, 858–868. [Google Scholar] [CrossRef]

- Khoshkava, V.; Kamal, M.R. Effect of cellulose nanocrystals (CNC) particle morphology on dispersion and rheological and mechanical properties of polypropylene/CNC nanocomposites. ACS Appl. Mater. Interfaces 2014, 6, 8146–8157. [Google Scholar] [CrossRef]

| Slurry Injection (SI) | Solution Injection (SoI) | Water Injection (WI) | |

|---|---|---|---|

| Main feed: |

|

|

|

| Downstream feed: |

|

|

|

| Advantages: |

|

|

|

| Disadvantages: |

|

|

|

| Polymer | Cellulose: Feed Type, Feed Concentration, Composite Conc. | Additive, Final Conc. | Fibrillation and Compounding | Results | Reference |

|---|---|---|---|---|---|

| PP (powder) MAPP | Never-dried bleached and unbleached Kraft pulp, 20–25% solids, Composites with up to 60% cellulose | - | Fibrillated and compounded in separate extrusion steps with 15 mm screw, L/D of 45; fibrillation extrusion described as kneading: 0 °C, 400 rpm, 400 g/h; compounding at 110–180 °C, 200 rpm, 300 g/h, venting at middle and end zone | After matrix dissolved, hierarchical fiber structure with diameters from sub-micron to 10s µm; tensile, flexural, and impact properties improved; tensile modulus doubled and strength increased 1.5 times; heat distortion increased by 53 °C; unbleached pulp resulted in higher tensile strength | Suzuki et al. 2013 [38] |

| PP (powder) MAPP | Never-dried bleached and unbleached Kraft pulp, 20–25% solids, Composites with 30–40% cellulose | Cationic polymer with primary amino group (CPPA), 3% | Fibrillated and compounded in separate extrusion steps with 15 mm screw, L/D of 45; fibrillation extrusion described as kneading: 0 °C, 400 rpm, 400 g/h; compounding at 110–180 °C, 200 rpm, 200 g/h, venting at middle and end zone | Fibers shown after fibrillation appear hierarchical with micron and sub-micron fibers; composites had improved tensile properties compared to PP; CPPA further improved tensile properties | Suzuki et al. 2014 [39] |

| High density polyethylene (HDPE) PP MAPP | Never-dried bleached pulp, 20–25% solids, Composites with 20% cellulose | Cationic polymer with primary amino group (CPPA), 4% | Fibrillation and compounding done in separate extrusion steps with 15 mm screw, L/D of 45; fibrillation extrusion described as kneading: 0 °C, 400 rpm, 400 g/h; compounding at 110–180 °C, 200 rpm, 200 g/h, venting at middle and end zone | After matrix dissolved, hierarchical fiber structure with diameters from sub-micron to ~10 µm; greater improvements of mechanical properties with HDPE than PP; fibrillation better in HDPE than PP; MAPP and CPPA improve fiber-polymer interaction; improved heat deflection and thermal expansion | Suzuki et al. 2016 [40] |

| PP (powder) MAPP | Never-dried bleached pulp, 20–25% solids, Composites with 30% cellulose | Cationic polymer with primary amino group (CPPA), 6% or 9% | Same as Suzuki et al. 2014; [40] compared to pre-mixing wet CNFs with PP, MAPP, and CPPA in a blender, followed by wet compounding at 110–180 °C, 200 rpm, 200 g/h | Twin screw fibrillation combined with subsequent wet compounding had higher tensile properties than first producing CNFs followed by wet compounding | Suzuki et al. 2017 [50] |

| Various examples, including HDPE, PP, and PLA | Various pulps, including alkenyl succinic anhydride (ASA)-modified never-dried bleached pulps | Various amounts of CaCO3, nucleating agents, antioxidants | This patent describes various combinations of water and solvent-based modification, fibrillation, and compounding; they suggest water content during compounding be less than 20% | Various examples showed modified cellulose resulted in composites with improved properties; they claim nanoscale fibrillation | Yano et al. 2016 [45] |

| LDPE | Microcrystalline cellulose (MCC), 92% solids, Composites with 5–30% | - | Attempted to use high-shear wet extrusion compounding to liberate MCC into CNCs; they mixed the MCC powder with polymer in the melt zone and injected water downstream; 100–1200 rpm, 150 °C | Using water and especially polymer powders instead of pellets improved dispersion; water improved discoloration from cellulose in composites; tensile stiffness improved, especially above 10% cellulose and elongation decreased | Soulestin et al. 2007 [65] |

| PCL | Hemp fibers, 77.5–90% solids, Composites with 20% fibers | - | High-shear extrusion was used to fibrillate and compound hemp fibers with PCL; fibers added either with PCL or downstream; 25 mm screw, L/D of 36; 100 °C or 140 °C; 100–400 rpm; 0.85 kg/h or 1.5 kg/h | Severe fibrillation occurred but not to nanoscale; tensile modulus and strength improved by factor of 2 or 3; Factors leading to higher fiber aspect ratio (e.g., higher moisture, 100 °C instead of 140 °C) generally gave higher tensile properties | Beaugrand and Berzin 2013 [66] |

| PCL (powder) | Bleached softwood Kraft pulp, acetylated and not 22% solids, Composites with 5–20% cellulose | - | PCL powder and pulp slurry were pre-mixed and fed into a twin screw microcompounder at 120 °C and 30 rpm for 5 min; following feeding, 100 rpm for ~15 min until water presumed evaporated | Cellulose was highly fibrillated but not to nanoscale; acetylated fibers performed best with tensile modulus and strength increased by (860% and 150%, respectively) | Lo Re et al. 2018 [42] |

| Polymer | CN | Additives | Compounding | Results | Reference |

|---|---|---|---|---|---|

| Fine powder of low density polyethylene (LDPE) | 0–15% CNCs/MCC | None | LDPE premixed with CNCs/MCC dispersion; dried to 8–10% moisture; wet compounded using roller blade mixer and then compression molded | Presence of water and premixing improved dispersion (visual assessment); increases in modulus and strength, reduction in strain to failure | Sapkota et al. 2017 [7] |

| PE | 0.5–5% oil palm CNF | 3% Maleated PE | 0.2% CNF dispersion wet compounded in internal mixer then compression molded. Compared with compression molded composites made from aligned strands from wet extrusion compounding. | Increases in strength and modulus over unfilled for all composites. Wet extrusion compounding yielded better dispersion than wet internal mixer compounding. Alignment of extruded filament led to alignment in composites and better strengths and moduli. | Yasim-Anuar et al. 2020 [60] |

| PP powder | Up to 60% MFC from never-dried bleached/unbleached Kraft pulp | Up to 6% MAPP | 20–25% solids pulp mixed with PP and MAPP then fibrillated in an extruder. Mixture was then wet compounded in a twin rotary roller mixer, ground, and compression molded. | Microfibrillated cellulose (MFC) did not appear to aggregate during wet compounding. Strengths and moduli increased over unfilled, failure strains decreased. Approach was successfully transferred to wet extrusion compounding process. | Suzuki et al. 2013 [38] |

| PLA powder | 1% CNCs | DTAC 1 (1:1 molar ratio with sulfates) 0 or 10% PVAc 2 | Polymer and CNC suspensions were pre-mixed prior to compounding in thermokinetic mixer at either 3700 or 6000 rpms. Discharge temperatures of 155 °C and 175 °C. Compounds were ground and films were extruded. | DTAC and PVAc improved dispersion and transparency. Samples compounded at high speed (low residence time) did not have significant molecular weight degradation | Sabo et al. 2020 [11] |

| Polyamide 6 (PA6) | 5% CNCs | None | Three compounding methods compared: Dry compounding of freeze-dried CNCs with PA6 in a thermokinetic mixer. Wet compounding of CNC dispersion with PA6 in a thermokinetic mixer. Solvent-blending of freeze-dried CNCs and PA6. All compounds were then injection molded. | CNC dispersion in wet compounding much better than dry but not as good as solvent blending. Dispersion particularly influenced elongational properties of composites. Thermal degradation of CNCs in wet compounded and solvent blended composites similar. Dry compounded much worse. | Clemons 2017 [8] |

| PP powder | Up to 7.5% treated CNCs | MAPP:CNC wt ratio of 1:1 or 1.5:1 | Wet compounding of treated CNC dispersion (10% solids), PP, and MAPP followed by compression molding. | CNC dispersion well below micron but not perfect. Rheology showed good network formation above percolation (~4.5%) at high MAPP level. | Clemons and Reiner 2020 [68] |

| PLA powder | 1% CNCs, with and without lignin | None | CNC suspension and PLA powder pre-mixed prior to compounding in thermokinetic mixer at 5500 rpm. Evaluated discharge setpoints of ~100 °C and 180 °C. Ground and extruded films. | Wet compounding resulted in films with improved mechanical and water vapor barrier properties compared to melt mixing freeze-dried CNCs. Lignin-containing CNCs did not perform as well | Sabo et al. 2019 [10] |

| PLA powder | 2% wood CNFs, with and without lactic acid esterification | None | PLA and CNF suspensions were pre-mixed prior to compounding in thermokinetic mixer. Discharge temperatures of 140 °C. Compounds ground and injection molded. | Esterification did not dramatically change CNFs but resulted in more transparent composites than CNFs without lactic acid grafted. | Lafia-Araga 2018 [69] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Clemons, C.; Sabo, R. A Review of Wet Compounding of Cellulose Nanocomposites. Polymers 2021, 13, 911. https://doi.org/10.3390/polym13060911

Clemons C, Sabo R. A Review of Wet Compounding of Cellulose Nanocomposites. Polymers. 2021; 13(6):911. https://doi.org/10.3390/polym13060911

Chicago/Turabian StyleClemons, Craig, and Ronald Sabo. 2021. "A Review of Wet Compounding of Cellulose Nanocomposites" Polymers 13, no. 6: 911. https://doi.org/10.3390/polym13060911