Assessment of Dimensional Stability, Biodegradability, and Fracture Energy of Bio-Composites Reinforced with Novel Pine Cone

Abstract

:1. Introduction

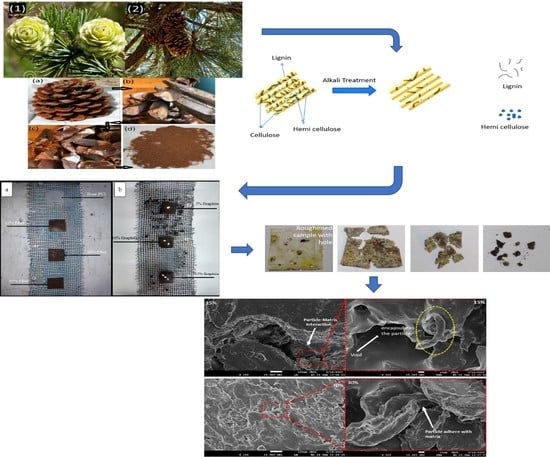

2. Experimentation

3. Results and Discussion

3.1. Water Absorptivity

3.2. Biodegradability

3.3. Fracture Energy

3.4. Morphology

4. Conclusions

- i.

- Compatibilising with graphite reduces the effect of the hydrophobic nature of pine cone and improves the interfacial adhesion at a molecular level, as well as diminishing the voids in the agglomerated fibres, thus imparting graphite composites with lower tendency for water absorption.

- ii.

- Bio-composites reinforced with 15–45 wt % of PCP showed higher bio-disintegration than neat PCL.

- iii.

- Bio-composites containing low graphite content also showed higher disintegration rate.

- iv.

- Fracture energy was found to have negative slope with increasing fibres from 0–45 weight fraction in the matrix. After increasing the weight fraction to 30%, the energy required for crack initiation was increased by 68%. Then it further diminishes as weight fraction of fibre was increased to 45%, due to the increase in void content.

- v.

- Microscopy of the composite fractured surfaces depicts the uniform dispersion of PCP particle embedded in PCL matrix at higher fraction of reinforcement. Pine cone particles (PCP) at 15 weight fractions in PCL matrix was observed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mohanty, A.K.; Misra, M.; Drzal, L.T. Sustainable bio-composites from renewable resources: Opportunity and challenges in the green material world. J. Polym. Environ. 2002, 10, 19–26. [Google Scholar] [CrossRef]

- Bachtiar, D.; Sapuan, S.M.; Hamdan, M.M. The effect of alkaline treatment on tensile properties of sugar palm fiber reinforced epoxy composites. Mater. Des. 2008, 29, 1285–1290. [Google Scholar] [CrossRef]

- Bledzki, A.K.; Gassan, J. Composites Reinforced with Cellulose based Fabric. Polym. Sci. 1999, 24, 221–274. [Google Scholar]

- Sharifah, H.A.; Martin, P.A. The effect of alkalization and fiber alignment on the mechanical and thermal properties of kenaf and hemp Bast fiber composites: Part 1—Polyester resin matrix. Compos. Sci. Technol. 2004, 64, 1219–1230. [Google Scholar]

- Shaik, D.S.; Kant, Y.; Mitra, D.; Singh, A.; Chandola, H.C.; Sateesh, M.; Chauhan, P. Impact of biomass burning on regional aerosol optical properties: A case study over northern India. J. Environ. Manag. 2019, 244, 328–343. [Google Scholar] [CrossRef] [PubMed]

- Saranya, K.R.L.; Reddy, C.S.; Rao, P.P. Estimating carbon emissions from forest fires over a decade in Similipal Biosphere Reserve, India. Remote Sens. Appl. Soc. Environ. 2016, 4, 61–67. [Google Scholar] [CrossRef]

- Schmerbeck, J.; Kohli, A.; Seeland, K. Ecosystem services and forest fires in India-context and policy implications from a case study in Andhra Pradesh. For. Policy Econ. 2015, 50, 337–346. [Google Scholar] [CrossRef]

- Hung, S.J.; Edelman, P.G. An overview of biodegradable polymers and biodegradation of polymers. In Degradable Polymers: Principles and Application; Scott, G., Gilead, D., Eds.; Springer: Berlin/Heidelberg, Germany, 1995; pp. 8–24. [Google Scholar]

- Wu, C.S. Physical Properties and Biodegradability of Maleated Polycaprolactone / Starch Composite. Polym. Degrad. Stab. 2003, 80, 127–134. [Google Scholar] [CrossRef] [Green Version]

- Sarikaya, E.; Çallioğlu, H.; Demirel, H. Production of epoxy composites reinforced by different natural fibers and their mechanical properties. Compos. Part B Eng. 2019, 167, 461–466. [Google Scholar] [CrossRef]

- Flynn, J.; Amiri, A.; Ulven, C. Hybridized carbon and flax fiber composites for tailored performance. Mater. Des. 2016, 102, 21–29. [Google Scholar] [CrossRef]

- Jha, K.; Tyagi, Y.K.; Yadav, A.S. Mechanical and thermal behaviour of biodegradable composites based on polycaprolactone with pine cone particle. Sādhanā 2018, 43, 135. [Google Scholar] [CrossRef] [Green Version]

- Echeverria, C.; Pahlevani, F.; Gaikwad, V.; Sahajwalla, V. The effect of microstructure, filler load and surface adhesion of marine bio-fillers, in the performance of hybrid wood-polypropylene particulate bio-composite. J. Clean. Prod. 2017, 154, 284–294. [Google Scholar] [CrossRef]

- Wu, K.J.; Wu, C.S.; Chang, J.S. Biodegradability and Mechanical Properties of Polycaprolactone Composites Encapsulating Phosphate-Solubilizing Bacterium Bacillus Sp. PG01. Process. Biochem. 2007, 42, 669–675. [Google Scholar] [CrossRef]

- Naira, L.S.; Laurencin, C.T. Biodegradable Polymers as Biomaterials. Prog. Polym. Sci. 2007, 32, 762–798. [Google Scholar] [CrossRef]

- Jha, K.; Kataria, R.; Verma, J.; Pradhan, S. Potential biodegradable matrices and fiber treatment for green composites: A review. AIMS Mater. Sci. 2019, 6, 119–138. [Google Scholar] [CrossRef]

- Kolybaba, M.; Tabil, L.G.; Panigrahi, S.; Crerar, W.J.; Powell, T.; Wang, B. Biodegradable polymers: Past, present and future. In ASABE/CSBE North Central Intersectional Meeting; American Society of Agricultural and Biological Engineers: St. Joseph, MI, USA, 2003; pp. 3–4. [Google Scholar]

- Liu, J.Y.; Reni, L.; Wei, Q.; Wu, J.L.; Liu, S.; Wang, Y.J.; Li, Y. Fabrication and Characterization of Polycaprolactone/Calcium Sulfate Whisker Composites. eXPRESS Polym. Lett. 2011, 5, 742–752. [Google Scholar] [CrossRef]

- Hajiha, H.; Sain, M.; Mei, L.H. Modification and characterization of Hemp and Sisal fibers. J. Nat. Fibers 2014, 11, 144–168. [Google Scholar] [CrossRef]

- Riedel, U. Natural fiber-reinforced biopolymers as construction materials—New discoveries. In Proceedings of the 2nd International Wood and Natural Fiber Composites Symposium, Kassel, Germany, 28–29 June 1999; pp. 28–29. [Google Scholar]

- Jha, K.; Kumar, R.; Verma, K.; Chaudhary, B.; Tyagi, Y.K.; Singh, S. Application of modified TOPSIS technique in deciding optimal combination for bio-degradable composite. Vacuum 2018, 157, 259–267. [Google Scholar] [CrossRef]

- Singh, H.; Singh, T. Effect of fillers of various sizes on mechanical characterization of natural fiber polymer hybrid composites: A review. Mater. Today Proc. 2019, 18, 5345–5350. [Google Scholar] [CrossRef]

- Pappu, A.; Thakur, V.K.; Patidar, R.; Asolekar, S.R.; Saxena, M. Recycling marble wastes and Jarosite wastes into sustainable hybrid composite materials and validation through Response Surface Methodology. J. Clean. Prod. 2019, 240, 118249. [Google Scholar] [CrossRef]

- Yousef, S.; Tatariants, M.; Bendikiene, R.; Denafas, G. Mechanical and thermal characterizations of non-metallic components recycled from waste printed circuit boards. J. Clean. Prod. 2017, 167, 271–280. [Google Scholar] [CrossRef]

- Mohan, P.K.; Kumar, A.; Mohite, P.M. Development of In-house Unidirectional Carbon/epoxy Prepregs and its Characterization for Aerospace Applications. Procedia Struct. Integr. 2019, 14, 176–183. [Google Scholar] [CrossRef]

- ISO. ISO 20200:2004. Plastics—Determination of the Degree of Disintegration of Plastic Materials Under Simulated Composting Conditions in a Laboratory-Scale Test; ISO: Geneva, Switzerland, 2004. [Google Scholar]

- Huang, G.; Sun, H. Effect of water absorption on the mechanical properties of glass/polyester composites. Mater. Des. 2007, 28, 1647–1650. [Google Scholar] [CrossRef]

- Shahinur, S.; Hasan, M. Jute/Coir/Banana Fiber Reinforced Bio-Composites: Critical Review of Design, Fabrication, Properties and Applications. In Encyclopedia of Renewable and Sustainable Materials; Elsevier Ltd.: Oxford, UK, 2019; pp. 751–756. [Google Scholar] [CrossRef]

- Bismarck, A.; Aranberri-Askargorta, I.; Springer, J. Surface characterization of flax, hemp and cellulose fibers; surface properties and the water uptake behavior. Polym. Compos. 2002, 23, 872–894. [Google Scholar] [CrossRef]

- Espert, A.; Vilaplana, F.; Karlsson, S. Comparison of water absorption in natural cellulosic fibers from wood and one-year crops in polypropylene composites and its influence on their mechanical properties. Compos. Part. A Appl. Sci. Manuf. 2004, 35, 1267–1276. [Google Scholar] [CrossRef]

- Chouzouri, G.; Xanthos, M. Degradation of aliphatic polyesters in the presence of inorganic fillers. J. Plast. Film. Sheeting 2007, 23, 19–36. [Google Scholar] [CrossRef]

- Dahiya, J.B.; Rana, S. Thermal degradation and morphological studies on cotton cellulose modified with various aryl phosphoro-dichloridites. Polym. Int. 2004, 53, 995–1002. [Google Scholar] [CrossRef]

- Wahit, M.U.; Akos, N.I.; Laftah, W.A. Influence of Natural Fibers on the Mechanical Properties and Biodegradation of Poly (lactic acid) and Poly(e-caprolactone) Composites: A Review. Polym. Compos. 2012, 33, 1045–1053. [Google Scholar] [CrossRef]

- Honma, T.; Zhao, L.; Asakawa, N.; Inoue, Y. Poly (ε-caprolactone)/chitin and Poly (e-caprolactone)/chitosan Blend Films with Compositional Gradients: Fabrication and their Biodegradability. Macromol. Biol. Sci. 2006, 6, 241–249. [Google Scholar] [CrossRef]

- Ludueña, L.; Vázquez, A.; Alvarez, V. Effect of lignocellulosic filler type and content on the behavior of polycaprolactone based eco-composites for packaging applications. Carbohydr. Polym. 2012, 87, 411–421. [Google Scholar] [CrossRef]

- Wu, C.S. A Comparison of the Structure, Thermal Properties, And Biodegradability of Polycaprolactone/Chitosan and Acrylic Acid Grafted Polycaprolactone/Chitosan. Polymer 2006, 46, 147–155. [Google Scholar] [CrossRef]

- Ilyas, R.A.; Sapuan, S.M.; Asyraf, M.R.M.; Dayana, D.A.Z.N.; Amelia, J.J.N.; Rani, M.S.A.; Norrrahim, M.N.F.; Nurazzi, N.M.; Aisyah, H.A.; Sharma, S.; et al. Polymer Composites Filled with Metal. Derivatives: A Review of Flame Retardants. Polymers 2021, 13, 1701. [Google Scholar] [CrossRef]

- Chohan, J.S.; Mittal, N.; Kumar, R.; Singh, S.; Sharma, S.; Dwivedi, S.P.; Saxena, A.; Chattopadhyaya, S.; Ilyas, R.A.; Le, C.H.; et al. Optimization of FFF Process Parameters by Naked Mole-Rat Algorithms with Enhanced Exploration and Exploitation Capabilities. Polymers 2021, 13, 1702. [Google Scholar] [CrossRef]

- Chohan, J.S.; Mittal, N.; Kumar, R.; Singh, S.; Sharma, S.; Singh, J.; Rao, K.V.; Mia, M.; Pimenov, D.Y.; Dwivedi, S.P. Mechanical Strength Enhancement of 3D Printed Acrylonitrile Butadiene Styrene Polymer Components Using Neural Network Optimization Algorithm. Polymers 2020, 12, 2250. [Google Scholar] [CrossRef] [PubMed]

- Singh, Y.; Singh, J.; Sharma, S. Multi-objective Optimization of Kerf-taper and Surface-roughness Quality Characteristics for Cutting-operation On Coir and Carbon Fibre Reinforced Epoxy Hybrid Polymeric Composites During CO2-Pulsed Laser-cutting Using RSM. Lasers Manuf. Mater. Process. 2021, 8, 157–182. [Google Scholar] [CrossRef]

- Sharma, S.; Singh, J.; Kumar, H.; Sharma, A.; Aggarwal, V.; Gill, A.; Jayarambabu, N.; Kailasa, S.; Rao, K.V. Utilization of rapid prototyping technology for the fabrication of an orthopedic shoe inserts for foot pain reprieve using thermo-softening viscoelastic polymers: A novel experimental approach. Meas. Control 2020, 53, 519–530. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Sharma, A.; Chohan, J.S. Process Parameter Optimization in Laser Cutting of Coir Fiber Reinforced Epoxy Composite—A Review. Mater. Today Proc. 2021, 47, 4738–4744. [Google Scholar] [CrossRef]

- Chohan, J.S.; Kumar, R.; Singh, T.B.; Singh, S.; Sharma, S.; Singh, J.; Mia, M.; Pimenov, D.Y.; Chattopadhyaya, S.; Dwivedi, S.P.; et al. Taguchi S/N and TOPSIS Based Optimization of Fused Deposition Modelling and Vapor Finishing Process for Manufacturing of ABS Plastic Parts. Materials 2020, 13, 5176. [Google Scholar] [CrossRef]

- Singh, Y.; Singh, J.; Sharma, S.; Nguyen, D.N. Fabrication and characterization of coir/carbon-fiber reinforced epoxy-based hybrid composite for helmet shells and sports-good applications: Influence of fiber surface modifications on the mechanical, thermal and morphological properties. J. Mater. Res. Technol. 2020, 9, 15593–15603. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Singh, J.; Ilyas, R.A.; Asyraf, M.R.M.; Razman, M.R. Critical Review of Biodegradable and Bioactive Polymer Composites for Bone Tissue Engineering and Drug Delivery Applications. Polymers 2021, 13, 2623. [Google Scholar] [CrossRef]

- Sharma, S.; Sudhakara, P.; Omran, A.A.B.; Singh, J.; Ilyas, R.A. Recent Trends and Developments in Conducting Polymer Nanocomposites for Multifunctional Applications. Polymers 2021, 13, 2898. [Google Scholar] [CrossRef] [PubMed]

| In % | CD-1 | CD-2 | CD-3 | CD-4 | CD-5 | CD-6 | CD-7 |

|---|---|---|---|---|---|---|---|

| Fibre | 0 | 15 | 30 | 45 | 45 | 45 | 45 |

| Matrix | 100 | 85 | 70 | 55 | 52.25 | 49.5 | 46.75 |

| Graphite | 0 | 0 | 0 | 0 | 2.75 | 5.5 | 8.25 |

| Samples | Percentages of Water-Uptake at Infinite Time (W∞) | Sorption Coefficient (S) | Diffusion Coefficient (D) (mm2/s) | Permeability Coefficient (P) (mm2/s) |

|---|---|---|---|---|

| 0% | 0.43 | 26.88 | 6.44 × 10−8 | 1.73 × 10−6 |

| 15% | 2.36 | 1.25 | 2.97× 10−5 | 3.72 × 10−5 |

| 30% | 8.21 | 2.77 | 6.05 × 10−6 | 1.68 × 10−5 |

| 45% | 20.99 | 2.12 | 1.04 × 10−5 | 2.20 × 10−5 |

| Samples | % of Water-Uptake at Infinite-Time (W∞) | Diffusion Coefficient (D) (mm2/s) | Sorption Coefficient (S) | Permeability Coefficient (P) (mm2/s) |

|---|---|---|---|---|

| CD-4 | 0.43 | 6.44064 × 10−8 | 26.875 | 3.71538 × 10−5 |

| CD-5 | 7.04 | 4.34 × 10−8 | 32.74419 | 1.42 × 10−6 |

| CD-6 | 10.2 | 3.1 × 10−7 | 12.24049 | 3.8 × 10−6 |

| CD-7 | 8.17 | 6.09 × 10−7 | 8.742643 | 5.32 × 10−6 |

| Samples | Theoretical Density (g/cm3) | Actual Density (g/cm3) | Void’s Volume (%) |

|---|---|---|---|

| CD-1 | 1.145 | 1.141 | 0.3 |

| CD-2 | 0.9707 | 0.92 | 5.2 |

| CD-3 | 0.9360 | 0.83 | 1.13 |

| CD-4 | 0.7983 | 0.805 | 6.8 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jha, K.; Tyagi, Y.K.; Kumar, R.; Sharma, S.; Huzaifah, M.R.M.; Li, C.; Ilyas, R.A.; Dwivedi, S.P.; Saxena, A.; Pramanik, A. Assessment of Dimensional Stability, Biodegradability, and Fracture Energy of Bio-Composites Reinforced with Novel Pine Cone. Polymers 2021, 13, 3260. https://doi.org/10.3390/polym13193260

Jha K, Tyagi YK, Kumar R, Sharma S, Huzaifah MRM, Li C, Ilyas RA, Dwivedi SP, Saxena A, Pramanik A. Assessment of Dimensional Stability, Biodegradability, and Fracture Energy of Bio-Composites Reinforced with Novel Pine Cone. Polymers. 2021; 13(19):3260. https://doi.org/10.3390/polym13193260

Chicago/Turabian StyleJha, Kanishka, Yogesh K. Tyagi, Rajeev Kumar, Shubham Sharma, Muhammad Roslim Muhammad Huzaifah, Changhe Li, Rushdan Ahmad Ilyas, Shashi Prakash Dwivedi, Ambuj Saxena, and Alokesh Pramanik. 2021. "Assessment of Dimensional Stability, Biodegradability, and Fracture Energy of Bio-Composites Reinforced with Novel Pine Cone" Polymers 13, no. 19: 3260. https://doi.org/10.3390/polym13193260