Design of Sustainable Biofuel Processes and Supply Chains: Challenges and Opportunities

Abstract

:1. Introduction

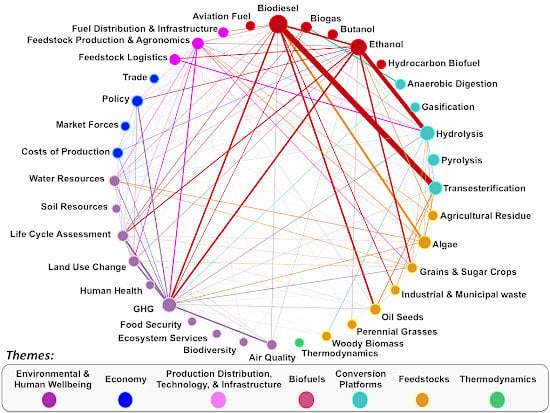

2. Emerging Biofuel Pathways

3. Bibliometric Analysis of Biofuel Literature

| Theme | Topic | Example Keywords |

|---|---|---|

| Environmental & Human Wellbeing | Food Security | Food Supply, Food Crop |

| Human Health | Mortality, Asthma | |

| GHGs | Greenhouse Gases, Carbon Dioxide | |

| Air Quality (Non-GHGs) | Particulate Matter, Volatile Organic Compounds | |

| Soil Resources | Soil Organic Carbon, Soil Fertility | |

| Land Use Change | Indirect Land Use Change, Direct Land Use Change | |

| Water Resources | Groundwater, Water Footprint | |

| Biodiversity | Wildlife, Biodiversity | |

| Life Cycle Assessment | Life Cycle Analysis, Life Cycle Assessment | |

| Ecosystem Services | Ecosystem Services, Ecosystems | |

| Economy | Cost of Production | Technoeconomic analysis, Infrastructure |

| Market Forces | Supply and Demand, Cost Competitiveness | |

| Policy | RFS2, EISA, LCFS | |

| Trade | Import, Export, Tariff | |

| Production Distribution, Technology & Infrastructure | Feedstock Production and Agronomics | Biomass Production, Agronomics |

| Feedstock Logistics | Pretreatment, Biomass transportation | |

| Fuel Distribution and Infrastructure | Pipeline, Fuel Storage | |

| Biofuels | Aviation Fuel | Aviation Fuel, Jet Fuel |

| Biodiesel | Biodiesel, Biodiesel Blend | |

| Ethanol | Ethanol, Lignocellulosic Ethanol | |

| Hydrocarbon Biofuel | Drop in replacement biofuel, Renewable Diesel | |

| Butanol | Butanol, Biobutanol | |

| Biogas | Biogas, Biomethane | |

| Conversion Platforms | Pyrolysis | Fast Pyrolysis, Pyrolysis oil |

| Gasification | Gasification, BTL | |

| Transesterification | Esterification, FAME | |

| Hydrolysis | Hydrolysis, Fermentation | |

| Anaerobic Digestion | Anaerobic Digestion | |

| Feedstocks | Woody Biomass | Willow, Poplar |

| Perennial Grasses | Switchgrass, Miscanthus | |

| Oil Seeds | Jatropha, Soybean, Rapeseed | |

| Algae | Microaglae, Macroalgae | |

| Feedstocks | Agricultural Residue | Sugarcane Bagasse, Corn Stover, Forest Residue |

| Industrial & Municipal Waste | Waste Cooking Oil, Vegetable Oil | |

| Grains & Sugar Crops | Corn, Wheat, Rye | |

| Thermodynamics | N/A | Exergy, Emergy |

4. Designing Sustainable Biofuel Supply Chains

4.1. Field Trials and Laboratory Scale Experiments

4.2. Process Scale

4.3. Modeling the Supply Chain and Life Cycle

4.3.1. Process LCA

4.3.2. EIO-LCA and Hybrid LCA

4.3.3. Attributional vs. Consequential LCA

4.4. Ecosystems Scale

4.5. Accounting for Multiple Objectives and Scales in Designing Sustainable Biofuel Processes/Supply Chains

4.6. Uncertainty and Variability

5. Conclusions and Outlook

Supplementary Files

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sarukhan, J.; Whyte, A.; Hassan, R.; Scholes, R.; Ash, N.; Carpenter, S.; Pingali, P.; Bennett, E.; Zurek, M.; Chopra, K. Millenium ecosystem assessment: Ecosystems and human well-being; WHO Press: Geneva, Switzerland, 2005. [Google Scholar]

- Steffen, W.; Richardson, K.; Rockström, J.; Cornell, S.E.; Fetzer, I.; Bennett, E.M.; Biggs, R.; Carpenter, S.R.; de Vries, W.; de Wit, C.A.; et al. Planetary boundaries: Guiding human development on a changing planet. Science 2015. [Google Scholar] [CrossRef] [PubMed]

- Hughes, T.P.; Carpenter, S.; Rockström, J.; Scheffer, M.; Walker, B. Multiscale regime shifts and planetary boundaries. Trends Ecol. Evol. 2013, 28, 389–395. [Google Scholar] [CrossRef] [PubMed]

- Steffen, W.; Persson, Å.; Deutsch, L.; Zalasiewicz, J.; Williams, M.; Richardson, K.; Crumley, C.; Crutzen, P.; Folke, C.; Gordon, L.; et al. The anthropocene: From global change to planetary stewardship. AMBIO 2011, 40, 739–761. [Google Scholar] [CrossRef] [PubMed]

- Rockstrom, J.; Steffen, W.; Noone, K.; Persson, A.; Chapin, F.S.; Lambin, E.F.; Lenton, T.M.; Scheffer, M.; Folke, C.; Schellnhuber, H.J.; et al. A safe operating space for humanity. Nature 2009, 461, 472–475. [Google Scholar] [CrossRef] [PubMed]

- EPA. Inventory of U.S. Greenhouse Gas Emissions and Sinks: 1990–2011; United States Environmental Protection Agency: Washington, DC, USA, 2015.

- Sissine, F. Energy Independence and Security Act of 2007: A Summary of Major Provisions; CRS Order Code RL34294; Library of Congress, Congressional Research Service: Washington, DC, USA, 2007.

- European Parliament and the Council of the European Union. Directive 2009/28/EC of the european parliament and of the council of 23 April 2009 on the promotion of the use of energy from renewable sources and amending and subsequently repealing directives 2001/77/EC and 2003/30/EC. Off. J. Eur. Union 2009, 52, 16–62. [Google Scholar]

- Fargione, J.; Hill, J.; Tilman, D.; Polasky, S.; Hawthorne, P. Land clearing and the biofuel carbon debt. Science 2008, 319, 1235–1238. [Google Scholar] [CrossRef] [PubMed]

- Melillo, J.M.; Reilly, J.M.; Kicklighter, D.W.; Gurgel, A.C.; Cronin, T.W.; Paltsev, S.; Felzer, B.S.; Wang, X.D.; Sokolov, A.P.; Schlosser, C.A. Indirect emissions from biofuels: How important? Science 2009, 326, 1397–1399. [Google Scholar] [CrossRef] [PubMed]

- McKone, T.E.; Nazaroff, W.W.; Berck, P.; Auffhammer, M.; Lipman, T.; Torn, M.S.; Masanet, E.; Lobscheid, A.; Santero, N.; Mishra, U.; et al. Grand challenges for life-cycle assessment of biofuels. Environ. Sci. Technol. 2011, 45, 1751–1756. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.R.D.; Inman, D.; Aden, A.; Heath, G.A. Environmental and sustainability factors associated with next-generation biofuels in the U.S.: What do we really know? Environ. Sci. Technol. 2009, 43, 4763–4775. [Google Scholar] [CrossRef] [PubMed]

- Perlack, R.D.; Stokes, B.J. Us Billion-ton Update: Biomass Supply for a Bioenergy and Bioproducts Industry; Oak Ridge National Laboratory: Oak Ridge, TN, USA, 2011.

- Nigam, P.S.; Singh, A. Production of liquid biofuels from renewable resources. Prog. Energy Combust. Sci. 2011, 37, 52–68. [Google Scholar] [CrossRef]

- Sims, R.E.H.; Mabee, W.; Saddler, J.N.; Taylor, M. An overview of second generation biofuel technologies. Bioresour. Technol. 2010, 101, 1570–1580. [Google Scholar] [CrossRef] [PubMed]

- Huber, G.W.; Dumesic, J.A. An overview of aqueous-phase catalytic processes for production of hydrogen and alkanes in a biorefinery. Catal. Today 2006, 111, 119–132. [Google Scholar] [CrossRef]

- Huber, G.W.; Iborra, S.; Corma, A. Synthesis of transportation fuels from biomass: Chemistry, catalysts, and engineering. Chem. Rev. 2006, 106, 4044–4098. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.K.; Chou, H.; Ham, T.S.; Lee, T.S.; Keasling, J.D. Metabolic engineering of microorganisms for biofuels production: From bugs to synthetic biology to fuels. Curr. Opin. Biotechnol. 2008, 19, 556–563. [Google Scholar] [CrossRef] [PubMed]

- Chheda, J.N.; Dumesic, J.A. An overview of dehydration, aldol-condensation and hydrogenation processes for production of liquid alkanes from biomass-derived carbohydrates. Catal. Today 2007, 123, 59–70. [Google Scholar] [CrossRef]

- Chheda, J.N.; Huber, G.W.; Dumesic, J.A. Liquid-phase catalytic processing of biomass-derived oxygenated hydrocarbons to fuels and chemicals. Angew. Chem. Int. Ed. 2007, 46, 7164–7183. [Google Scholar] [CrossRef] [PubMed]

- Chheda, J.N.; Roman-Leshkov, Y.; Dumesic, J.A. Production of 5-hydroxymethylfurfural and furfural by dehydration of biomass-derived mono- and poly-saccharides. Green Chem. 2007, 9, 342–350. [Google Scholar] [CrossRef]

- Huber, G.W.; Chheda, J.N.; Barrett, C.J.; Dumesic, J.A. Production of liquid alkanes by aqueous-phase processing of biomass-derived carbohydrates. Science 2005, 308, 1446–1450. [Google Scholar] [CrossRef] [PubMed]

- Huber, G.W.; Shabaker, J.W.; Dumesic, J.A. Raney Ni-Sn catalyst for H2 production from biomass-derived hydrocarbons. Science 2003, 300, 2075–2077. [Google Scholar] [CrossRef] [PubMed]

- Olcay, H.; Subrahmanyam, A.V.; Xing, R.; Lajoie, J.; Dumesic, J.A.; Huber, G.W. Production of renewable petroleum refinery diesel and jet fuel feedstocks from hemicellulose sugar streams. Energy Environ. Sci. 2013, 6, 205–216. [Google Scholar] [CrossRef]

- Bond, J.Q.; Upadhye, A.A.; Olcay, H.; Tompsett, G.A.; Jae, J.; Xing, R.; Alonso, D.M.; Wang, D.; Zhang, T.; Kumar, R.; et al. Production of renewable jet fuel range alkanes and commodity chemicals from integrated catalytic processing of biomass. Energy Environ. Sci. 2014, 7, 1500–1523. [Google Scholar] [CrossRef]

- Bond, J.Q.; Alonso, D.M.; Wang, D.; West, R.M.; Dumesic, J.A. Integrated catalytic conversion of γ-valerolactone to liquid alkenes for transportation fuels. Science 2010, 327, 1110–1114. [Google Scholar] [CrossRef] [PubMed]

- Zaimes, G.G.; Soratana, K.; Harden, C.L.; Landis, A.E.; Khanna, V. Biofuels via fast pyrolysis of perennial grasses: A life cycle evaluation of energy consumption and greenhouse gas emissions. Environ. Sci. Technol. 2015, 49, 10007–10018. [Google Scholar] [CrossRef] [PubMed]

- Bridgwater, A.V. Review of fast pyrolysis of biomass and product upgrading. Biomass Bioenergy 2012, 38, 68–94. [Google Scholar] [CrossRef]

- French, R.; Czernik, S. Catalytic pyrolysis of biomass for biofuels production. Fuel Process. Technol. 2010, 91, 25–32. [Google Scholar] [CrossRef]

- Wright, M.M.; Daugaard, D.E.; Satrio, J.A.; Brown, R.C. Techno-economic analysis of biomass fast pyrolysis to transportation fuels. Fuel 2010, 89, S2–S10. [Google Scholar] [CrossRef]

- Patwardhan, P.R.; Brown, R.C.; Shanks, B.H. Understanding the fast pyrolysis of lignin. ChemSusChem 2011, 4, 1629–1636. [Google Scholar] [CrossRef] [PubMed]

- Patwardhan, P.R.; Brown, R.C.; Shanks, B.H. Product distribution from the fast pyrolysis of hemicellulose. ChemSusChem 2011, 4, 636–643. [Google Scholar] [CrossRef] [PubMed]

- Elliott, D.C.; Hart, T.R.; Neuenschwander, G.G.; Rotness, L.J.; Zacher, A.H. Catalytic hydroprocessing of biomass fast pyrolysis bio-oil to produce hydrocarbon products. Environ. Prog. Sustain. Energy 2009, 28, 441–449. [Google Scholar] [CrossRef]

- Wang, K.; Brown, R.C. Catalytic pyrolysis of corn dried distillers grains with solubles to produce hydrocarbons. ACS Sustain. Chem. Eng. 2014, 2, 2142–2148. [Google Scholar] [CrossRef]

- Brewer, C.E.; Schmidt-Rohr, K.; Satrio, J.A.; Brown, R.C. Characterization of biochar from fast pyrolysis and gasification systems. Environ. Prog. Sustain. Energy 2009, 28, 386–396. [Google Scholar] [CrossRef]

- Graber, E.; Harel, Y.M.; Kolton, M.; Cytryn, E.; Silber, A.; David, D.R.; Tsechansky, L.; Borenshtein, M.; Elad, Y. Biochar impact on development and productivity of pepper and tomato grown in fertigated soilless media. Plant Soil 2010, 337, 481–496. [Google Scholar] [CrossRef]

- Laird, D.A.; Fleming, P.; Davis, D.D.; Horton, R.; Wang, B.; Karlen, D.L. Impact of biochar amendments on the quality of a typical midwestern agricultural soil. Geoderma 2010, 158, 443–449. [Google Scholar] [CrossRef]

- Major, J.; Lehmann, J.; Rondon, M.; Goodale, C. Fate of soil-applied black carbon: Downward migration, leaching and soil respiration. Glob. Change Biol. 2010, 16, 1366–1379. [Google Scholar] [CrossRef]

- Vaccari, F.P.; Baronti, S.; Lugato, E.; Genesio, L.; Castaldi, S.; Fornasier, F.; Miglietta, F. Biochar as a strategy to sequester carbon and increase yield in durum wheat. Eur. J. Agron. 2011, 34, 231–238. [Google Scholar] [CrossRef]

- Verheijen, F.G.A.; Graber, E.R.; Ameloot, N.; Bastos, A.C.; Sohi, S.; Knicker, H. Biochars in soils: New insights and emerging research needs. Eur. J. Soil Sci. 2014, 65, 22–27. [Google Scholar] [CrossRef]

- Woolf, D.; Amonette, J.E.; Street-Perrott, F.A.; Lehmann, J.; Joseph, S. Sustainable biochar to mitigate global climate change. Nat. Commun. 2010, 1, 56. [Google Scholar] [CrossRef] [PubMed]

- Agrawal, R.; Singh, N.R. Synergistic routes to liquid fuel for a petroleum-deprived future. AIChE J. 2009, 55, 1898–1905. [Google Scholar] [CrossRef]

- Dauenhauer, P.J.; Dreyer, B.J.; Degenstein, N.J.; Schmidt, L.D. Millisecond reforming of solid biomass for sustainable fuels. Angew. Chem. Int. Ed. 2007, 46, 5864–5867. [Google Scholar] [CrossRef] [PubMed]

- Brune, D.E.; Lundquist, T.J.; Benemann, J.R. Microalgal Biomass for Greenhouse Gas Reductions: Potential for Replacement of Fossil Fuels and Animal Feeds. J. Environ. Eng. 2009, 135, 1136–1144. [Google Scholar] [CrossRef]

- Weyer, K.M.; Bush, D.R.; Darzins, A.; Willson, B.D. Theoretical maximum algal oil production. BioEnergy Res. 2010, 3, 204–213. [Google Scholar] [CrossRef]

- Chisti, Y. Biodiesel from microalgae. Biotechnol. Adv. 2007, 25, 13. [Google Scholar] [CrossRef] [PubMed]

- Yang, J.; Xu, M.; Zhang, X.; Hu, Q.; Sommerfeld, M.; Chen, Y. Life-cycle analysis on biodiesel production from microalgae: Water footprint and nutrients balance. Bioresour. Technol. 2011, 102, 159–165. [Google Scholar] [CrossRef] [PubMed]

- Brennan, L.; Owende, P. Biofuels from microalgae—A review of technologies for production, processing, and extractions of biofuels and co-products. Renew. Sustain. Energy Rev. 2010, 14, 557–577. [Google Scholar] [CrossRef]

- Luo, D.; Hu, Z.; Choi, D.G.; Thomas, V.M.; Realff, M.J.; Chance, R.R. Life cycle energy and greenhouse gas emissions for an ethanol production process based on blue-green algae. Environ. Sci. Technol. 2010, 44, 8670–8677. [Google Scholar] [CrossRef] [PubMed]

- Ehimen, E.A.; Sun, Z.F.; Carrington, C.G.; Birch, E.J.; Eaton-Rye, J.J. Anaerobic digestion of microalgae residues resulting from the biodiesel production process. Appl. Energy 2011, 88, 3454–3463. [Google Scholar] [CrossRef]

- Sialve, B.; Bernet, N.; Bernard, O. Anaerobic digestion of microalgae as a necessary step to make microalgal biodiesel sustainable. Biotechnol. Adv. 2009, 27, 409–416. [Google Scholar] [CrossRef] [PubMed]

- Tilman, D.; Hill, J.; Lehman, C. Carbon-negative biofuels from low-input high-diversity grassland biomass. Science 2006, 314, 1598–1600. [Google Scholar] [CrossRef] [PubMed]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Amon, T.; Hobbs, P.J. Bioenergy from permanent grassland—A review: 2. Combustion. Bioresour. Technol. 2009, 100, 4945–4954. [Google Scholar] [CrossRef] [PubMed]

- Prochnow, A.; Heiermann, M.; Plöchl, M.; Linke, B.; Idler, C.; Amon, T.; Hobbs, P.J. Bioenergy from permanent grassland—A review: 1. Biogas. Bioresour. Technol. 2009, 100, 4931–4944. [Google Scholar] [CrossRef] [PubMed]

- Van Meerbeek, K.; Appels, L.; Dewil, R.; van Beek, J.; Bellings, L.; Liebert, K.; Muys, B.; Hermy, M. Energy potential for combustion and anaerobic digestion of biomass from low-input high-diversity systems in conservation areas. GCB Bioenergy 2015, 7, 888–898. [Google Scholar] [CrossRef]

- Soratana, K.; Harden, C.L.; Zaimes, G.G.; Rasutis, D.; Antaya, C.L.; Khanna, V.; Landis, A.E. The role of sustainability and life cycle thinking in U.S. Biofuels policies. Energy Policy 2014, 75, 316–326. [Google Scholar] [CrossRef]

- Naik, S.N.; Goud, V.V.; Rout, P.K.; Dalai, A.K. Production of first and second generation biofuels: A comprehensive review. Renew. Sustain. Energy Rev. 2010, 14, 578–597. [Google Scholar] [CrossRef]

- Demirbas, A. Political, economic and environmental impacts of biofuels: A review. Appl. Energy 2009, 86, S108–S117. [Google Scholar] [CrossRef]

- Soratana, K.; Khanna, V.; Landis, A.E. Re-envisioning the renewable fuel standard to minimize unintended consequences: A comparison of microalgal diesel with other biodiesels. Appl. Energy 2013, 112, 194–204. [Google Scholar] [CrossRef]

- Ballew, B.S. Elsevier’s scopus® database. J. Electron. Resour. Med. Libr. 2009, 6, 245–252. [Google Scholar] [CrossRef]

- Ridley, C.E.; Clark, C.M.; LeDuc, S.D.; Bierwagen, B.G.; Lin, B.B.; Mehl, A.; Tobias, D.A. Biofuels: Network analysis of the literature reveals key environmental and economic unknowns. Environ. Sci. Technol. 2012, 46, 1309–1315. [Google Scholar] [CrossRef] [PubMed]

- Van Eck, N.J.; Waltman, L. Software survey: Vosviewer, a computer program for bibliometric mapping. Scientometrics 2010, 84, 523–538. [Google Scholar] [CrossRef] [PubMed]

- Carley, K.M.; DeReno, M. Ora: Organization Risk Analyzer, Ora User’s Guide; Technical Report; School of Computer Science, Institute for Software Research, Carnegie Mellon University: Pittsburgh, PA, USA, 2006. [Google Scholar]

- Dias de Oliveira, M.E.; Vaughan, B.E.; Rykiel, E.J. Ethanol as fuel: Energy, carbon dioxide balances, and ecological footprint. BioScience 2005, 55, 593–602. [Google Scholar] [CrossRef]

- Pimentel, D.; Patzek, T.; Cecil, G. Ethanol production: Energy, economic, and environmental losses. In Reviews of Environmental Contamination and Toxicology; Whitacre, D., Ware, G., Nigg, H., Doerge, D., Albert, L., Voogt, P., Gerba, C., Hutzinger, O., Knaak, J., Mayer, F., et al., Eds.; Springer: New York, NY, USA, 2007; Volume 189, pp. 25–41. [Google Scholar]

- Guinee, J.B.; Heijungs, R.; Huppes, G.; Zamagni, A.; Masoni, P.; Buonamici, R.; Ekvall, T.; Rydberg, T. Life cycle assessment: Past, present, and future. Environ. Sci. Technol. 2010, 45, 90–96. [Google Scholar] [CrossRef] [PubMed]

- Clark, J.H. Green chemistry: Challenges and opportunities. Green Chem. 1999, 1, 1–8. [Google Scholar] [CrossRef]

- Bakshi, B.R.; Fiksel, J. The quest for sustainability: Challenges for process systems engineering. AIChE J. 2003, 49, 1350–1358. [Google Scholar] [CrossRef]

- Bakshi, B.R. A thermodynamic framework for ecologically conscious process systems engineering. Comput. Chem. Eng. 2002, 26, 269–282. [Google Scholar] [CrossRef]

- Bakshi, B.R.; Ziv, G.; Lepech, M.D. Techno-ecological synergy: A framework for sustainable engineering. Environ. Sci. Technol. 2015, 49, 1752–1760. [Google Scholar] [CrossRef] [PubMed]

- Hanes, R.J.; Bakshi, B.R. Process to planet: A multiscale modeling framework for sustainable engineering. AIChE J. 2015. [Google Scholar] [CrossRef]

- Hanes, R.J.; Bakshi, B.R. Sustainable process design by the process to planet framework. AIChE J. 2015. [Google Scholar] [CrossRef]

- Zhuang, K.; Bakshi, B.R.; Herrgård, M.J. Multi-scale modeling for sustainable chemical production. Biotechnol. J. 2013, 8, 973–984. [Google Scholar] [CrossRef] [PubMed]

- Resasco, D.E.; Crossley, S.P. Implementation of concepts derived from model compound studies in the separation and conversion of bio-oil to fuel. Catal. Today 2014. [Google Scholar] [CrossRef]

- Zhao, H.Y.; Li, D.; Bui, P.; Oyama, S.T. Hydrodeoxygenation of guaiacol as model compound for pyrolysis oil on transition metal phosphide hydroprocessing catalysts. Appl. Catal. A: Gen. 2011, 391, 305–310. [Google Scholar] [CrossRef]

- Pham, T.N.; Sooknoi, T.; Crossley, S.P.; Resasco, D.E. Ketonization of carboxylic acids: Mechanisms, catalysts, and implications for biomass conversion. ACS Catal. 2013, 3, 2456–2473. [Google Scholar] [CrossRef]

- Lapuerta, M.; Villajos, M.; Agudelo, J.R.; Boehman, A.L. Key properties and blending strategies of hydrotreated vegetable oil as biofuel for diesel engines. Fuel Process. Technol. 2011, 92, 2406–2411. [Google Scholar] [CrossRef]

- Darnoko, D.; Cheryan, M. Kinetics of palm oil transesterification in a batch reactor. J. Am. Oil Chem. Soc. 2000, 77, 1263–1267. [Google Scholar] [CrossRef]

- Nie, L.; Resasco, D.E. Kinetics and mechanism of m-cresol hydrodeoxygenation on a Pt/SiO2 catalyst. J. Catal. 2014, 317, 22–29. [Google Scholar] [CrossRef]

- Christian, D.G.; Riche, A.B.; Yates, N.E. Growth, yield and mineral content of Miscanthus giganteus grown as a biofuel for 14 successive harvests. Ind. Crops Prod. 2008, 28, 320–327. [Google Scholar] [CrossRef]

- Guretzky, J.; Biermacher, J.; Cook, B.; Kering, M.; Mosali, J. Switchgrass for forage and bioenergy: Harvest and nitrogen rate effects on biomass yields and nutrient composition. Plant Soil 2011, 339, 69–81. [Google Scholar] [CrossRef]

- Thomason, W.E.; Raun, W.R.; Johnson, G.V.; Taliaferro, C.M.; Freeman, K.W.; Wynn, K.J.; Mullen, R.W. Switchgrass response to harvest frequency and time and rate of applied nitrogen. J. Plant Nutr. 2005, 27, 1199–1226. [Google Scholar] [CrossRef]

- Vicente, G.; Coteron, A.; Martinez, M.; Aracil, J. Application of the factorial design of experiments and response surface methodology to optimize biodiesel production. Ind. Crops Prod. 1998, 8, 29–35. [Google Scholar] [CrossRef]

- Nair, S.S.; Kang, S.; Zhang, X.; Miguez, F.E.; Izaurralde, R.C.; Post, W.M.; Dietze, M.C.; Lynd, L.R.; Wullschleger, S.D. Bioenergy crop models: Descriptions, data requirements, and future challenges. GCB Bioenergy 2012, 4, 620–633. [Google Scholar] [CrossRef]

- Yin, Y.; Zhang, X.; Lin, D.; Yu, H.; Wang, J.A.; Shi, P. GEPIC-VR model: A GIS-based tool for regional crop drought risk assessment. Agric. Water Manag. 2014, 144, 107–119. [Google Scholar] [CrossRef]

- Aspen Plus, version 11; Aspen technology Inc.: Bedford, MA, USA, 2009.

- Anex, R.P.; Aden, A.; Kazi, F.K.; Fortman, J.; Swanson, R.M.; Wright, M.M.; Satrio, J.A.; Brown, R.C.; Daugaard, D.E.; Platon, A.; et al. Techno-economic comparison of biomass-to-transportation fuels via pyrolysis, gasification, and biochemical pathways. Fuel 2010, 89, S29–S35. [Google Scholar] [CrossRef]

- Zaimes, G.; Khanna, V. Microalgal biomass production pathways: Evaluation of life cycle environmental impacts. Biotechnol. Biofuels 2013, 6, 88. [Google Scholar] [CrossRef] [PubMed]

- Zaimes, G.G.; Khanna, V. Environmental sustainability of emerging algal biofuels: A comparative life cycle evaluation of algal biodiesel and renewable diesel. Environ. Prog. Sustain. Energy 2013, 32, 926–936. [Google Scholar] [CrossRef]

- Agusdinata, D.B.; Zhao, F.; Ileleji, K.; DeLaurentis, D. Life cycle assessment of potential biojet fuel production in the United States. Environ. Sci. Technol. 2011, 45, 9133–9143. [Google Scholar] [CrossRef] [PubMed]

- Pourhashem, G.; Spatari, S.; Boateng, A.A.; McAloon, A.J.; Mullen, C.A. Life cycle environmental and economic tradeoffs of using fast pyrolysis products for power generation. Energy Fuels 2013, 27, 2578–2587. [Google Scholar] [CrossRef]

- Dang, Q.; Yu, C.; Luo, Z. Environmental life cycle assessment of bio-fuel production via fast pyrolysis of corn stover and hydroprocessing. Fuel 2014, 131, 36–42. [Google Scholar] [CrossRef]

- Clarens, A.F.; Nassau, H.; Resurreccion, E.P.; White, M.A.; Colosi, L.M. Environmental impacts of algae-derived biodiesel and bioelectricity for transportation. Environ. Sci. Technol. 2011, 45, 7554–7560. [Google Scholar] [CrossRef] [PubMed]

- Vasudevan, V.; Stratton, R.W.; Pearlson, M.N.; Jersey, G.R.; Beyene, A.G.; Weissman, J.C.; Rubino, M.; Hileman, J.I. Environmental performance of algal biofuel technology options. Environ. Sci. Technol. 2012, 46, 2451–2459. [Google Scholar] [CrossRef] [PubMed]

- Wang, M.; Han, J.; Dunn, J.B.; Cai, H.; Elgowainy, A. Well-to-wheels energy use and greenhouse gas emissions of ethanol from corn, sugarcane and cellulosic biomass for us use. Environ. Res. Lett. 2012, 7, 045905. [Google Scholar] [CrossRef]

- Garcia, D.J.; You, F. Supply chain design and optimization: Challenges and opportunities. Comput. Chem. Eng. 2015, in press. [Google Scholar] [CrossRef]

- Curran, M.A. Environmental life-cycle assessment. Int. J. Life Cycle Assess. 1996, 1, 179–179. [Google Scholar] [CrossRef]

- Ecoinvent Centre. Ecoinvent Data v2.0; Swiss Centre for Life Cycle Inventories: Dubendorf, Switzerland, 2007. [Google Scholar]

- Ciroth, A. Ict for environment in life cycle applications openlca—A new open source software for life cycle assessment. Int. J. Life Cycle Assess. 2007, 12, 209–210. [Google Scholar] [CrossRef]

- USLCI. Life-Cycle Inventory, v. 1.6. 0; National Renewable Energy Laboratory: Golden, CO, USA, 2008.

- Wang, M. The Greenhouse Gases, Regulated Emissions, and Energy Use in Transportation Model: Version 1.5; Argonne National Laboratory, U.S. Department of Energy: Lemont, IL, USA, 2008.

- Zaimes, G.G.; Khanna, V. The role of allocation and coproducts in environmental evaluation of microalgal biofuels: How important? Sustain. Energy Technol. Assess. 2014, 7, 247–256. [Google Scholar] [CrossRef]

- Wang, M.; Huo, H.; Arora, S. Methods of dealing with co-products of biofuels in life-cycle analysis and consequent results within the U.S. Context. Energy Policy 2011, 39, 5726–5736. [Google Scholar] [CrossRef]

- Liu, X.; Clarens, A.F.; Colosi, L.M. Algae biodiesel has potential despite inconclusive results to date. Bioresour. Technol. 2012, 104, 803–806. [Google Scholar] [CrossRef] [PubMed]

- Sieverding, H.L.; Bailey, L.M.; Hengen, T.J.; Clay, D.E.; Stone, J.J. Meta-analysis of soybean-based biodiesel. J. Environ. Qual. 2015. [Google Scholar] [CrossRef]

- Leontief, W. Input-output analysis. New Palgrave. Dict. Econ. 1987, 2, 860–864. [Google Scholar]

- Lave, L.B. Using input-output analysis to estimate economy-wide discharges. Environ. Sci. Technol. 1995, 29, 420A–426A. [Google Scholar] [CrossRef]

- Zhang, Y.; Baral, A.; Bakshi, B.R. Accounting for ecosystem services in life cycle assessment, part ii: Toward an ecologically based LCA. Environ. Sci. Technol. 2010, 44, 2624–2631. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Singh, S.; Bakshi, B.R. Accounting for ecosystem services in life cycle assessment, part i: A critical review. Environ. Sci. Technol. 2010, 44, 2232–2242. [Google Scholar] [CrossRef] [PubMed]

- Baral, A.; Bakshi, B.R. Thermodynamic metrics for aggregation of natural resources in life cycle analysis: Insight via application to some transportation fuels. Environ. Sci. Technol. 2009, 44, 800–807. [Google Scholar] [CrossRef] [PubMed]

- Baral, A.; Bakshi, B.R.; Smith, R.L. Assessing resource intensity and renewability of cellulosic ethanol technologies using eco-LCA. Environ. Sci. Technol. 2012, 46, 2436–2444. [Google Scholar] [CrossRef] [PubMed]

- Ukidwe, N.U.; Bakshi, B.R. Thermodynamic accounting of ecosystem contribution to economic sectors with application to 1992 U.S. Economy. Environ. Sci. Technol. 2004, 38, 4810–4827. [Google Scholar] [CrossRef] [PubMed]

- Sciubba, E. On the second-law inconsistency of emergy analysis. Energy 2010, 35, 3696–3706. [Google Scholar] [CrossRef]

- Sciubba, E.; Ulgiati, S. Emergy and exergy analyses: Complementary methods or irreducible ideological options? Energy 2005, 30, 1953–1988. [Google Scholar] [CrossRef]

- Dewulf, J.; van Langenhove, H.; Muys, B.; Bruers, S.; Bakshi, B.R.; Grubb, G.F.; Paulus, D.M.; Sciubba, E. Exergy: Its potential and limitations in environmental science and technology. Environ. Sci. Technol. 2008, 42, 2221–2232. [Google Scholar] [CrossRef] [PubMed]

- Hau, J.L.; Bakshi, B.R. Promise and problems of emergy analysis. Ecol. Model. 2004, 178, 215–225. [Google Scholar] [CrossRef]

- Gaudreau, K.; Fraser, R.; Murphy, S. The tenuous use of exergy as a measure of resource value or waste impact. Sustainability 2009, 1, 1444–1463. [Google Scholar] [CrossRef]

- Rugani, B.; Benetto, E. Improvements to emergy evaluations by using life cycle assessment. Environ. Sci. Technol. 2012, 46, 4701–4712. [Google Scholar] [CrossRef] [PubMed]

- Raugei, M.; Rugani, B.; Benetto, E.; Ingwersen, W.W. Integrating emergy into LCA: Potential added value and lingering obstacles. Ecol. Model. 2014, 271, 4–9. [Google Scholar] [CrossRef]

- Romero, J.C.; Linares, P. Exergy as a global energy sustainability indicator. A review of the state of the art. Renew. Sustain. Energy Rev. 2014, 33, 427–442. [Google Scholar] [CrossRef]

- Suh, S.; Lenzen, M.; Treloar, G.J.; Hondo, H.; Horvath, A.; Huppes, G.; Jolliet, O.; Klann, U.; Krewitt, W.; Moriguchi, Y.; et al. System boundary selection in life-cycle inventories using hybrid approaches. Environ. Sci. Technol. 2004, 38, 657–664. [Google Scholar] [CrossRef] [PubMed]

- Ekvall, T.; Weidema, B. System boundaries and input data in consequential life cycle inventory analysis. Int. J. Life Cycle Assess. 2004, 9, 161–171. [Google Scholar] [CrossRef]

- Schmidt, J. System delimitation in agricultural consequential LCA. Int. J. Life Cycle Assess. 2008, 13, 350–364. [Google Scholar] [CrossRef]

- Weidema, B.; Frees, N.; Nielsen, A.-M. Marginal production technologies for life cycle inventories. Int. J. Life Cycle Assess. 1999, 4, 48–56. [Google Scholar] [CrossRef]

- Earles, J.M.; Halog, A. Consequential life cycle assessment: A review. Int. J. Life Cycle Assess. 2011, 16, 445–453. [Google Scholar] [CrossRef]

- Reinhard, J.; Zah, R. Global environmental consequences of increased biodiesel consumption in Switzerland: Consequential life cycle assessment. J. Clean. Prod. 2009, 17, S46–S56. [Google Scholar] [CrossRef]

- Lund, H.; Mathiesen, B.; Christensen, P.; Schmidt, J. Energy system analysis of marginal electricity supply in consequential LCA. Int. J. Life Cycle Assess. 2010, 15, 260–271. [Google Scholar] [CrossRef]

- Lesage, P.; Deschênes, L.; Samson, R. Evaluating holistic environmental consequences of brownfield management options using consequential life cycle assessment for different perspectives. Environ. Manag. 2007, 40, 323–337. [Google Scholar] [CrossRef] [PubMed]

- Britz, W. Capri Modelling System Documentation (Common Agricultural Policy Regional Impact Analysis); Institute for Agricultural Policy, Market Research and Economic Sociology, University Bonn: Bonn, Germany, 2005. [Google Scholar]

- Westhoff, P.; Baur, R.; Stephens, D.L.; Meyers, W.H. Fapri Us Crops Model Documentation; Center for Agricultural and Rural Development, Iowa State University: Ames, IA, USA, 1990. [Google Scholar]

- Rosegrant, M.W.; Msangi, S.; Ringler, C.; Sulser, T.B.; Zhu, T.; Cline, S.A. International Model for Policy Analysis Agricultural Commodities and Trade (Impact): Model Description; International Food Policy Research Institute: Washington, DC, USA, 2008. [Google Scholar]

- Adams, D.M.; Alig, R.J.; Callaway, J.M.; McCarl, B.A.; Winnett, S.M. The Forest and Agricultural Sector Optimization Model (Fasom): Model Structure and Policy Applications; U.S. Department of Agriculture, Pacific Northwest Research Station: Portland, OR, USA, 1996.

- Narayanan, B.G.; Walmsley, T.L. Global trade, assistance, and production: The GTAP 7 data base. Center for Global Trade Analysis, Purdue University. Available online: https://www.gtap.agecon.purdue.edu/databases/v7/v7_doco.asp (accessed on 13 August 2015).

- Fishbone, L.G.; Abilock, H. Markal, a linear-programming model for energy systems analysis: Technical description of the BNL version. Int. J. Energy Res. 1981, 5, 353–375. [Google Scholar] [CrossRef]

- Alcamo, J. Image 2.0: Integrated Modeling of Global Climate Change; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1994. [Google Scholar]

- Veldkamp, A.; Fresco, L.O. Clue: A conceptual model to study the conversion of land use and its effects. Ecol. Model. 1996, 85, 253–270. [Google Scholar] [CrossRef]

- Scher, I.; Koomey, J. Is accurate forecasting of economic systems possible? Clim. Change 2011, 104, 473–479. [Google Scholar] [CrossRef]

- Plevin, R.J.; Beckman, J.; Golub, A.A.; Witcover, J.; O’Hare, M. Carbon accounting and economic model uncertainty of emissions from biofuels-induced land use change. Environ. Sci. Technol. 2015, 49, 2656–2664. [Google Scholar] [CrossRef] [PubMed]

- Wender, B.A.; Foley, R.W.; Prado-Lopez, V.; Ravikumar, D.; Eisenberg, D.A.; Hottle, T.A.; Sadowski, J.; Flanagan, W.P.; Fisher, A.; Laurin, L.; et al. Illustrating anticipatory life cycle assessment for emerging photovoltaic technologies. Environ. Sci. Technol. 2014, 48, 10531–10538. [Google Scholar] [CrossRef] [PubMed]

- Scown, C.D.; Nazaroff, W.W.; Mishra, U.; Strogen, B.; Lobscheid, A.B.; Masanet, E.; Santero, N.J.; Horvath, A.; McKone, T.E. Lifecycle greenhouse gas implications of us national scenarios for cellulosic ethanol production. Environ. Res. Lett. 2012, 7, 014011. [Google Scholar] [CrossRef]

- Brentner, L.B.; Eckelman, M.J.; Zimmerman, J.B. Combinatorial life cycle assessment to inform process design of industrial production of algal biodiesel. Environ. Sci. Technol. 2011, 45, 7060–7067. [Google Scholar] [CrossRef] [PubMed]

- Weidema, B.P. Market Information in Life Cycle Assessment; Miljøstyrelsen: København, Denmark, 2003; Volume 863. [Google Scholar]

- Daily, G.C.; Polasky, S.; Goldstein, J.; Kareiva, P.M.; Mooney, H.A.; Pejchar, L.; Ricketts, T.H.; Salzman, J.; Shallenberger, R. Ecosystem services in decision making: Time to deliver. Front. Ecol. Environ. 2009, 7, 21–28. [Google Scholar] [CrossRef]

- Neupane, B.; Halog, A.; Lilieholm, R.J. Environmental sustainability of wood-derived ethanol: A life cycle evaluation of resource intensity and emissions in maine, USA. J. Clean. Prod. 2013, 44, 77–84. [Google Scholar] [CrossRef]

- Zaimes, G.G.; Khanna, V. Assessing the critical role of ecological goods and services in microalgal biofuel life cycles. RSC Adv. 2014, 4, 44980–44990. [Google Scholar] [CrossRef]

- Costanza, R.; d’Arge, R.; de Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Limburg, K.; Naeem, S.; O’Neill, R.V.; Paruelo, J.; et al. The value of the world’s ecosystem services and natural capital. Nature 1997, 387, 253–260. [Google Scholar] [CrossRef]

- Costanza, R.; d’Arge, R.; de Groot, R.; Farber, S.; Grasso, M.; Hannon, B.; Limburg, K.; Naeem, S.; O’Neill, R.V.; Paruelo, J.; et al. The value of ecosystem services: Putting the issues in perspective. Ecol. Econ. 1998, 25, 67–72. [Google Scholar] [CrossRef]

- Farber, S.C.; Costanza, R.; Wilson, M.A. Economic and ecological concepts for valuing ecosystem services. Ecol. Econ. 2002, 41, 375–392. [Google Scholar] [CrossRef]

- Hau, J.L.; Bakshi, B.R. Expanding exergy analysis to account for ecosystem products and services. Environ. Sci. Technol. 2004, 38, 3768–3777. [Google Scholar] [CrossRef] [PubMed]

- Izaurralde, R.C.; McGill, W.B.; Williams, J.R. Development and Application of the Epic Model for Carbon Cycle, Greenhouse-Gas Mitigation, and Biofuel Studies; Pacific Northwest National Laboratory (PNNL): Richland, WA, USA, 2012.

- Gassman, P.W.; Reyes, M.R.; Green, C.H.; Arnold, J.G. Soil and water assessment tool: Historical development, applications, and future research directions. Trans. ASABE 2007. [Google Scholar] [CrossRef]

- Wang, X.; Gassman, P.W.; Williams, J.R.; Potter, S.; Kemanian, A.R. Modeling the impacts of soil management practices on runoff, sediment yield, maize productivity, and soil organic carbon using apex. Soil Tillage Res. 2008, 101, 78–88. [Google Scholar] [CrossRef]

- Tallis, H.T.; Ricketts, T.; Guerry, A.D.; Wood, S.A.; Sharp, R.; Nelson, E.; Ennaanay, D.; Wolny, S.; Olwero, N.; Vigerstol, K. InVEST 2.2.0 User’s Guide. Available online: http://data.naturalcapitalproject.org/invest-releases/documentation/2_2_0/ (accessed on 13 August 2015).

- Hall, C.A.; Balogh, S.; Murphy, D.J. What is the minimum EROI that a sustainable society must have? Energies 2009, 2, 25–47. [Google Scholar] [CrossRef]

- Hall, C.A.S.; Lambert, J.G.; Balogh, S.B. EROI of different fuels and the implications for society. Energy Policy 2014, 64, 141–152. [Google Scholar] [CrossRef]

- Bakshi, B.R. Methods and tools for sustainable process design. Curr. Opin. Chem. Eng. 2014, 6, 69–74. [Google Scholar] [CrossRef]

- Cambero, C.; Sowlati, T. Assessment and optimization of forest biomass supply chains from economic, social and environmental perspectives—A review of literature. Renew. Sustain. Energy Rev. 2014, 36, 62–73. [Google Scholar] [CrossRef]

- Krajnc, N.; Domac, J. How to model different socio-economic and environmental aspects of biomass utilisation: Case study in selected regions in slovenia and croatia. Energy Policy 2007, 35, 6010–6020. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; Rasinmäki, J.; van Orshoven, J. Methods to optimise the design and management of biomass-for-bioenergy supply chains: A review. Renew. Sustain. Energy Rev. 2014, 31, 657–670. [Google Scholar] [CrossRef]

- Baños, R.; Manzano-Agugliaro, F.; Montoya, F.G.; Gil, C.; Alcayde, A.; Gómez, J. Optimization methods applied to renewable and sustainable energy: A review. Renew. Sustain. Energy Rev. 2011, 15, 1753–1766. [Google Scholar] [CrossRef]

- Biegler, L.T.; Grossmann, I.E.; Westerberg, A.W. Systematic Methods for Chemical Process Design; Prentice Hall PTR: Upper Saddle River, NJ, USA, 1997. [Google Scholar]

- Biegler, L.T. Nonlinear Programming: Concepts, Algorithms, and Applications to Chemical Processes; SIAM: Philadelphia, PA, USA, 2010; Volume 10. [Google Scholar]

- Kim, K.-J.; Smith, R.L. Systematic procedure for designing processes with multiple environmental objectives. Environ. Sci. Technol. 2005, 39, 2394–2405. [Google Scholar] [CrossRef] [PubMed]

- Hoffmann, V.H.; Hungerbühler, K.; McRae, G.J. Multiobjective screening and evaluation of chemical process technologies. Ind. Eng. Chem. Res. 2001, 40, 4513–4524. [Google Scholar] [CrossRef]

- Zamboni, A.; Bezzo, F.; Shah, N. Spatially explicit static model for the strategic design of future bioethanol production systems. 2. Multi-objective environmental optimization. Energy Fuels 2009, 23, 5134–5143. [Google Scholar] [CrossRef]

- Zamboni, A.; Shah, N.; Bezzo, F. Spatially explicit static model for the strategic design of future bioethanol production systems. 1. Cost minimization. Energy Fuels 2009, 23, 5121–5133. [Google Scholar] [CrossRef]

- De Meyer, A.; Cattrysse, D.; van Orshoven, J. A generic mathematical model to optimise strategic and tactical decisions in biomass-based supply chains (optimass). Eur. J. Oper. Res. 2015, 245, 247–264. [Google Scholar] [CrossRef]

- Čuček, L.; Varbanov, P.S.; Klemeš, J.J.; Kravanja, Z. Total footprints-based multi-criteria optimisation of regional biomass energy supply chains. Energy 2012, 44, 135–145. [Google Scholar] [CrossRef]

- Mele, F.D.; Kostin, A.M.; Guillén-Gosálbez, G.; Jiménez, L. Multiobjective model for more sustainable fuel supply chains. A case study of the sugar cane industry in argentina. Ind. Eng. Chem. Res. 2011, 50, 4939–4958. [Google Scholar] [CrossRef]

- Yue, D.; Kim, M.A.; You, F. Design of sustainable product systems and supply chains with life cycle optimization based on functional unit: General modeling framework, mixed-integer nonlinear programming algorithms and case study on hydrocarbon biofuels. ACS Sustain. Chem. Eng. 2013, 1, 1003–1014. [Google Scholar] [CrossRef]

- López, P.R.; Galán, S.G.; Reyes, N.R.; Jurado, F. A method for particle swarm optimization and its application in location of biomass power plants. Int. J. Green Energy 2008, 5, 199–211. [Google Scholar] [CrossRef]

- Venema, H.; Calamai, P. Bioenergy systems planning using location-allocation and landscape ecology design principles. Ann. Oper. Res. 2003, 123, 241–264. [Google Scholar] [CrossRef]

- Ayoub, N.; Martins, R.; Wang, K.; Seki, H.; Naka, Y. Two levels decision system for efficient planning and implementation of bioenergy production. Energy Convers. Manag. 2007, 48, 709–723. [Google Scholar] [CrossRef]

- Gebreslassie, B.H.; Yao, Y.; You, F. Design under uncertainty of hydrocarbon biorefinery supply chains: Multiobjective stochastic programming models, decomposition algorithm, and a comparison between cvar and downside risk. AIChE J. 2012, 58, 2155–2179. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multiobjective optimization coupled with life cycle assessment and input-output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef]

- Awudu, I.; Zhang, J. Uncertainties and sustainability concepts in biofuel supply chain management: A review. Renew. Sustain. Energy Rev. 2012, 16, 1359–1368. [Google Scholar] [CrossRef]

- Lloyd, S.M.; Ries, R. Characterizing, propagating, and analyzing uncertainty in life-cycle assessment: A survey of quantitative approaches. J. Ind. Ecol. 2007, 11, 161–179. [Google Scholar] [CrossRef]

- Lo, S.-C.; Ma, H.-W.; Lo, S.-L. Quantifying and reducing uncertainty in life cycle assessment using the bayesian monte carlo method. Sci. Total Environ. 2005, 340, 23–33. [Google Scholar] [CrossRef] [PubMed]

- Huijbregts, M. Uncertainty and variability in environmental life-cycle assessment. Int. J. Life Cycle Assess. 2002, 7, 173. [Google Scholar] [CrossRef]

- Cherubini, F.; Strømman, A.H. Life cycle assessment of bioenergy systems: State of the art and future challenges. Bioresour. Technol. 2011, 102, 437–451. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Bae, J.; Kim, J.; Suh, S. Replacing gasoline with corn ethanol results in significant environmental problem-shifting. Environ. Sci. Technol. 2012, 46, 3671–3678. [Google Scholar] [CrossRef] [PubMed]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zaimes, G.G.; Vora, N.; Chopra, S.S.; Landis, A.E.; Khanna, V. Design of Sustainable Biofuel Processes and Supply Chains: Challenges and Opportunities. Processes 2015, 3, 634-663. https://doi.org/10.3390/pr3030634

Zaimes GG, Vora N, Chopra SS, Landis AE, Khanna V. Design of Sustainable Biofuel Processes and Supply Chains: Challenges and Opportunities. Processes. 2015; 3(3):634-663. https://doi.org/10.3390/pr3030634

Chicago/Turabian StyleZaimes, George G., Nemi Vora, Shauhrat S. Chopra, Amy E. Landis, and Vikas Khanna. 2015. "Design of Sustainable Biofuel Processes and Supply Chains: Challenges and Opportunities" Processes 3, no. 3: 634-663. https://doi.org/10.3390/pr3030634