Abstract

Adoption of the design for disassembly (DfD) concept is suggested as a promising strategy to cope with the climate targets and increase circular economy in the construction sector. Yet, the concept is little used partially due to technical challenges, including inadequate information about demolition and the characteristics of components. This study aims to investigate the demands for information linked to new concrete components with the purpose of reuse. In the building phase, concrete components cause the majority of emissions. Thus, these components also have the greatest potential for CO2 emissions savings. A comprehensive list of information related to DfD concrete components and their characteristics was gathered in a workshop with experts of DfD concrete elements. Furthermore, the stakeholders of DfD components data processing were considered. The results of this study may support the adoption of DfD with concrete components as it provides information for designers and builders to implement in early phases of building projects.

Export citation and abstract BibTeX RIS

Original content from this work may be used under the terms of the Creative Commons Attribution 4.0 license. Any further distribution of this work must maintain attribution to the author(s) and the title of the work, journal citation and DOI.

1. Introduction

The construction industry has a strong connection to the deterioration of natural systems (Lamb et al 2021), as it is the largest consumer of raw materials each year (Krausmann et al 2009). Moreover, buildings are responsible for approximately a fourth of the global carbon emissions (IEA 2023). Concrete, which is the most common building material and man-made material in the world (Habert et al 2020), accounts for one third of the construction sectors' emissions (Bajželj et al 2013). Due to the extent of the concrete industry, it also has a fundamental role in the battle against climate change and global warming (Adesina 2020, Bertin et al 2022). The current linear economy, which is based on the conversion of natural resources into waste via production, poorly coincides with the objectives of this fight. The negative impact on the natural environment could be limited by adopting circular economy, which relies on the principles of maintaining the value of products, materials, and resources for as long as possible (European commission 2015). In the construction sector, the adoption of these principles of circular economy is still rather limited, as, for example, more than 80% of construction waste ends up in landfills (Cornet 2019, Chong et al 2023). Wider implementation of circular economy requires new strategies as well as innovative policy measures that support the aims of reducing CO2 emissions and other actions negatively effecting the environment (Nußholz et al 2019).

Reuse of building components is suggested as a strategy to put the circular economy concept into reality in the built environment (Eberhardt et al 2019a, Minunno et al 2020). However, concrete elements have been found to be poorly suitable for reuse due to connections, as well as difficulties in handling, transportation (Mattaraia et al 2023), and taking them apart without damaging the components (Densley Tingley 2012). Designing components for disassembly provides an alternative to the reuse of existing building components. This strategy takes into account the reuse practices, such as connections between individual materials and components, and the inter-relationships of building elements, with the aim of providing the highest reuse or recycling value at the end of the buildings' useful life (Guy et al 2006). As concrete building can be divided into two main practices and a combination of both the two: cast-in-situ and precast (Salama 2017), DfD can be utilized logically only when building with precast components (Salama 2017).

Originally, design for disassembly (DfD), also known as design for deconstruction, has been considered as a tool to simplify products, improve quality, and lower manufacturing and assembly costs and shorter time to market (Boothroyd and Alting 1992). Later, the environmental aspects of DfD were noticed, but primarily as a method to enable easier recycling (Boothroyd and Alting 1992). The principles of DfD are often adopted in remanufacturing in the automotive industry (Reike et al 2018). In the building sector, the ideas of design for deconstruction were presented as early as in the 1970's by the architect Cristopher Alexander (Thormark 2007). In the 1990's the concept was developed further by such architects as Francis Duffy and Stuard Brand (Thormark 2007). However, these concepts were not widely utilized in building design worldwide. In the last few years, the attention towards DfD in building design has rapidly increased (Ostapska et al 2021). Authorities, organizations, and companies in the construction sector have studied the concept further, and developed guidelines for DfD (Thormark 2007). Furthermore, corporations have started to integrate DfD principles in their projects, and pilot projects have been implemented, for example Eberhardt et al (2019b) and Minunno et al (2020).

Despite the great environmental, social, and economic benefits that the DfD concept could bring for the construction sector, multiple barriers, including financial, marking, technical and regulatory challenges still impede it (Densley Tingley et al 2017, Tleuken et al 2022). The adaptation might require, for example, introduce of innovative connection methods, component design, and material development (Roxas et al 2023). Furthermore, a lack of information, especially of the physical and mechanical characteristics of DfD components, has given cause for concerns (Iacovidou and Purnell 2017, Cai and Waldmann 2019). On the other hand, a huge amount of data is reported to cause problems in utilizing and storing (Wong and Zhou 2015, Bilal et al 2016, Matarneh et al 2018). Moreover, the current literature does not comprehensively recognize the appropriate data demands for DfD component to facilitate their reuse. For these reasons, this study aims to fill the research gap of appropriate data by investigating the required information of a component to enable its reuse. The study focuses on concrete components as these components have a major effect on the emissions of the construction sector. Due to the challenges in reusing conventional concrete components, the study is limited to DfD concrete components. In addition, the study aims to find out the stakeholders who are needed in the process of data gathering, saving, and managing during the entire lifespan of an element.

Even though DfD concrete components are not yet on the market, the development of DfD element technology and producers' interest are on the increase. This study investigated the required data through a workshop, in which half of the participants were concrete component or connection technology business representatives with experience of DfD concrete component pilot projects, and the rest of the attendees were also familiar with the DfD concept in the building sector.

2. Literature review—DfD component data facilitating reuse

Reuse of building components has multiple barriers concerning data attached to components and buildings. Lack of information concerning the demolition phase and release of components is detected as a barrier of building component reuse (Sanchez et al 2021). In addition, inadequate data of components' characteristics (Honic et al 2019a, Bellini and Bang 2022) and materials impede reuse. Furthermore, the management of and saving information of building design and demolition, in the long-term, is perceived to be a challenge (Mattaraia et al 2023). Also, investigating the load capacity and integrity of building components is seen as an arduous task (Yeoh et al 2018).

Even though the abovementioned challenges relate to the reuse of building components already attached to buildings, similar kinds of concerns have been expressed to be present in the reuse of DfD components if the required data is not available in the demolition phase of buildings with DfD components (Iacovidou and Purnell 2017, Cai and Waldmann 2019). As this conundrum has been noticed, ISO standard 20887 (ISO 20887 2020) provides information of documentation, including details of design and connection features, supporting DfD adaptation. Furthermore, scholars have suggested options for solving the challenges with information. Mattaraia et al (2023) and Sanchez et al (2021) have recommended wider use of building information modeling (BIM) as an answer to these challenges. Kim and Kim (2020) as well as Rau and Oberhuber (2017) have suggested adopting material passport, which in building sector is a digital document that records the characteristics of materials and components in products embedded in building in order to facilitate recycling and reuse (Luscuere 2017, Honic et al 2019b), and material bank, which enables the materials and components from demolished buildings to be reused in new building (Cai and Waldmann 2019). Also, material passports are recommended to be used along with the implementation of BIM (Honic et al 2021). Even though multiple material passport solutions have been presented by scholars (Çetin et al 2021), these frameworks have been criticized to remain mainly conceptual and not include user perspectives (Çetin et al 2023).

To support the implementation of DfD Iacovidou and Purnell (2017) have offered a typology system, including information required to enable the reuse of construction components. Moreover, Iacovidou et al (2021) have presented the idea of digital components passports to support the reuse of construction components. This passport can use radio frequency identification for capturing information about the technical properties and quality of the component, over long periods of time, and this data can be integrated into BIM databases to provide higher value for stakeholders (Iacovidou et al 2021). By improving tracking, Dervishaj et al (2023) have presented promising results of using QR codes, near-field communication, and Bluetooth tags, with BIM, to support reuse of prefabricated concrete components. Also, artificial intelligence, machine learning techniques, and laser scanning have been suggested to the methods to address data of products for facilitating reuse of building components (Çetin et al 2023).

2.1. BIM facilitating reuse

Generally, BIM can be considered as an important tool for enabling the reuse of DfD components, as it is widely used in design processes, and it offers comprehensive information about building geometry and its' objects but also provides a set of semantic information about the function, materials, costs and relationships between objects (Borrmann et al 2018, Kim and Kim 2020). Even though BIM offers a solution for information management and saving, current practices cannot handle the issues of updating the data in later phases of the lifecycle. Hence, the BIM might not correspond to reality after repairs and modifications. Furthermore, details of connections between components are typically not represented in BIM. In addition, the compilation of BIM, with extensive information of all components, is still a rather laborious process, as effective automatic practices are not widely used. In the context of DfD, Lukianova et al (2022) have also noticed multiple concerns in BIM data extraction automation, including differing data structures and exchange formats, use of different classification and systems between project partners, collaborative work with various linked files, and software compatibility issues.

To facilitate the reuse of DfD components, multiple authors have developed BIM-based tools and methods. Akbarnezhad et al (2014), first, presented BIM with additional attributes, with the aim of finding the most sustainable deconstruction strategy. These attributes provide information that can be used for determining DfD components' suitability for reuse and recycling. Even though the model may offer important data for reuse, the attributes in this model are added manually, so the process is rather laborious. Yeoh et al (2018) provided a method, which is based on the strategy of compiling two separate BIM models: a 'Supply' BIM, which contains information for DfD components' first usage, and a 'Demand' BIM, which contains data for subsequent use. At the reusage phase, these models are synchronized, and the components suitable for reuse are detected through this process. Kim and Kim (2023) have also compiled a BIM-based design support tool to evaluate the suitability of components for deconstruction and reuse. Akinade et al (2015) have developed a BIM-based Deconstructability Assessment Score (BIM-DAS), which can be used, already in the design phase, for measuring the extent to which a building can be disassembled. Honic et al (2019a) generated a BIM-based material passport to enable the assessment of the recycling potential and environmental impacts of building materials. Even though these BIM-based methods and tools provide information about how to measure the sustainability of components for DfD and their deconstructability, they provide only fragmented knowledge of the information required of DfD components for reuse at a subsequent phase. Broader information of components is more typically presented in the context of material passports and material banks, as these tools are suggested to effectively facilitate the reuse of components (Cai and Waldmann 2019).

2.2. Material passports and banks facilitating the reuse of components

Information in material passports and banks can be provided to project stakeholders through the application of a BIM authoring tool or a web-based platform (Bertin et al 2020, Jayasinghe and Waldmann 2020). A material passport is a digital tool that contains information about building components and materials embedded in a building (Anastasiades et al 2020, Atta et al 2021). A material bank refers to a database of these passports or a storage of component information. According to Cai and Waldmann (2019), a material bank may contain information of assessment, conditioning, storage, and certification of materials and components. A material bank is needed to establish a database of the materials and components in a building (Geldermans 2016, Jayasinghe and Waldmann 2020) but it can be considered also as a collaboration platform, in which the component or material information can be stored (Cha and Lu 2021). The information material passports and material banks may contain is presented in table 1. Typically, a material passport contains information about components' physical and chemical properties. This categorization is used, for example, in the EU Horizon 2020 project Building as Material Banks (Heinrich and Lang 2019). The data presented in these tools might facilitate the reuse of components as it tackles the challenges of inadequate data (Honic et al 2019a).

Table 1. Data presented in a material passport or a material bank.

| Category | Detail | Author |

|---|---|---|

| General information | Specification code, standard | (Kim and Kim 2020) |

| Element type, element name, identification mark | (Munaro et al 2019, Jayasinghe and Waldmann 2020) | |

| Manufacturer and supplier documentation | (Heinrich and Lang 2019) | |

| Cost | (Kim and Kim 2020) | |

| LCA | (Heinrich and Lang 2019, Munaro et al 2019, Kim and Kim 2020) | |

| LCC | (Kim and Kim 2020) | |

| Location | (Kim and Kim 2020) | |

| Updates during operations | (Munaro et al 2019) | |

| Physical characteristics | Dimensions, volume | (Heinrich and Lang 2019, Jayasinghe and Waldmann 2020) |

| Radius, curvature, volume | (Jayasinghe and Waldmann 2020) | |

| Load-carrying capacity, stability | (Cai and Waldmann 2019, Heinrich and Lang 2019) | |

| Density | (Heinrich and Lang 2019, Jayasinghe and Waldmann 2020) | |

| Elastic modulus, compressive strength, tensile strength, shear strength | (Jayasinghe and Waldmann 2020) | |

| Creep | (Jayasinghe and Waldmann 2020) | |

| Durability | (Jayasinghe and Waldmann 2020) | |

| Thermal conductivity | (Jayasinghe and Waldmann 2020) | |

| Fire resistance, specific heat | (Heinrich and Lang 2019, Jayasinghe and Waldmann 2020) | |

| Coefficient of thermal expansion | (Jayasinghe and Waldmann 2020) | |

| Building physics (U-value, acoustics, porosity) | (Heinrich and Lang 2019) | |

| Optical information (color, surface, transmission, reflectivity) | (Heinrich and Lang 2019) | |

| Information of ageing and deterioration | (Jayasinghe and Waldmann 2020) | |

| Type of connection, including shape of the connection and the specification of the connecting members | (Cai and Waldmann 2019, Munaro et al 2019, Kim and Kim 2020) | |

| Instruction for handling, installation, transportation, and storage | (Heinrich and Lang 2019, Munaro et al 2019, Jayasinghe and Waldmann 2020) | |

| Design for deconstruction, instruction for installation, instruction for extraction | (Munaro et al 2019, Jayasinghe and Waldmann 2020) | |

| Components' location in a building | (Munaro et al 2019, Jayasinghe and Waldmann 2020, Kim and Kim 2020) | |

| Remaining life/use period of materials/components | (Munaro et al 2019, Kim and Kim 2020) | |

| Maintenance and cleaning | (Munaro et al 2019) | |

| Verifications made during use | (Munaro et al 2019) | |

| Chemical/material characteristics | Chemical composition and attributes of material | (Munaro et al 2019, Jayasinghe and Waldmann 2020, Kim and Kim 2020) |

| Toxicological information, safety | (Heinrich and Lang 2019, Munaro et al 2019, Jayasinghe and Waldmann 2020) | |

| Certification information of materials | (Heinrich and Lang 2019) | |

| Complementary material | (Munaro et al 2019) | |

| Reuse and recycling potentials of components and materials | (Heinrich and Lang 2019, Heisel and Rau-Oberhuber 2020, Kim and Kim 2020) |

Whereas the adoption of BIM is common in construction projects, the use of material passports and material banks is still limited (Kim and Kim 2020). The use of these tools is not currently required, and entering data into these systems is also considered to be a laborious task (Kim and Kim 2020, Giorgi et al 2022). In addition, as a building contains a set of varied components, the content of the data facilitating the reuse of certain kinds of DfD components needs to be carefully studied first, as heavy information attached to a BIM is claimed to hinder navigation inside the model (Asgharzadeh 2019). Thus, the data entered to the BIM or other collaboration platforms should all be useful in the lifecycle of components. Due to these challenges, it is clear that several issues concerning data type, entering, managing and saving need to be solved before DfD may become common practice.

2.3. Required information of DfD components

Besides the information provided in material passports or material banks, some scholars have presented certain requirements and propositions regarding the data of DfD components to enable their reuse. This information, presented in literature, has been collected into table 2. This data is largely similar to the information presented in material passports and banks, but since it concerns DfD components, in particular, it also addresses temporal and connection perspectives more closely.

Table 2. The information required of DfD components to enable their reuse.

| Information required | Author |

|---|---|

| Properties and characteristics of components (e.g. dimensions, strength, stiffness, stress status, durability requirements, standard, composition) | (Iacovidou and Purnell 2017, Yeoh et al 2018, Cai and Waldmann 2019, Bertin et al 2020) |

| Structural function | (Yeoh et al 2018, Bertin et al 2020) |

| Materials of components | (Yeoh et al 2018, Cai and Waldmann 2019, Bertin et al 2020) |

| Disassembly-ability of components | (Cai and Waldmann 2019) |

| Nature of original use | (Iacovidou and Purnell 2017) |

| Service life of a component | (Bertin et al 2020) |

| Functional requirements of components | (Cai and Waldmann 2019) |

| Connection details and relationship between different components | (Iacovidou and Purnell 2017, Yeoh et al 2018, Cai and Waldmann 2019, Bertin et al 2020) |

| Connection and disassembly methods | (Iacovidou and Purnell 2017, Cai and Waldmann 2019) |

| Exposure conditions | (Iacovidou and Purnell 2017) |

| Potential damages of components | (Cai and Waldmann 2019) |

| Residual performance tests, resource diagnosis | (Bertin et al 2020) |

| Product cost and reusability levels of components | (Cai and Waldmann 2019) |

| Economic or technological requirements of components | (Cai and Waldmann 2019) |

| A digital building model | (Bertin et al 2020) |

| As-built model/document | (Bertin et al 2020) |

The information presented above provides knowledge of data required for enabling the reuse of construction components, generally. Hence, it does not concern the specific characteristics of DfD concrete components. Studies focusing on DfD concrete components are few, and they mainly concentrate on structural issues, such as connections, e.g. Xiao et al (2017), or environmental impacts, e.g. Eberhardt et al (2019b) and Joensuu et al (2022). To our knowledge, no study of the extensive information to be linked with prefabricated concrete components has been conducted.

It must be noted that entering information into the systems and managing it has been found to be laborious work (Giorgi et al 2022). Thus, storing information that is not needed is also superfluous. As concrete elements are structural components of a building, DfD concrete components are basically factors that can be reused only after the demolition of a building. These components are not switched or repaired during the usage phase. Moreover, concrete components are typically rather simple in form and contain only few materials. Hence, DfD concrete elements and their associated data may significantly differ in various characteristics from other DfD components. As studies on the information to be linked with DfD components concern these components, in general, this study aims to investigate the data concerning DfD concrete components, in particular.

3. Material and method

This study of the required data of DfD concrete component characteristics was conducted through a workshop. The invitation to this workshop was presented to all of the six contributory organizations of the research project investigating business related to DfD concrete components. These partners involved companies, operating in concrete element business globally, and organizations, using these products. A total of nine experts of the building sector expressed their willingness and participated in this three-hour workshop. All the experts, including research and development managers of concrete components and concrete component connection techniques, chief business officers, researchers, an architect, and a structural engineer, were aware of the DfD concept. All the experts from the concrete industry had practical experience of DfD concrete components, and they had been involved in DfD concrete component pilot projects. Furthermore, the researchers participating in the workshop had studied the DfD concept from various viewpoints. In the workshop, the participants received an explanation of the study's procedure, and written consents were obtained from all participants.

In the beginning of the workshop, a short introduction was given to all participants into the general background of DfD criteria and the definitions of material passports and material banks. Then, the participants were randomly divided into two groups. The first group was asked to consider the information required to be collected and stored of DfD concrete components to enable the reuse of these components. The second group was asked to consider the question of 'Who owns and stores the data and which stakeholders should be involved in this process?' The participants were asked to enter their ideas in visual and written form on a shared paper. In the next stage, the participants switched their tasks, and continued working on the questions presented earlier to the other group. In this stage, the participants saw the output of the other group.

After the workshop, participants' data was digitally transformed, and topics related to collecting and storing information about DfD concrete components were thematically categorized.

4. Results

4.1. Information required of DfD concrete components

The first aim of the study was to compose a list of information required to be collected with the purpose of later reuse of DfD concrete components. This information was produced in the workshop, in listing form. This data was divided into eight categories, by the authors, as follows: general, physical, material, connections, adjoining components, BIM, use-phase, and subsequent phase. These categories were formed on the basis of the main theme of each matter. The information produced in the workshop, classified into the categories, is presented in table 3.

Table 3. Required information of DfD concrete elements to facilitate the reuse of components.

| Category | Information |

|---|---|

| General | ID, identification mark |

| Specification code, component type, component name | |

| Producer of component | |

| Time of production | |

| Useful life | |

| Dismountable/non-dismountable connection | |

| Owner of the building | |

| Location of the building | |

| Product-specific disassembly/reuse plan | |

| Product-specific reuse plan | |

| Plans for detach, disassemble and reassembly | |

| Physical | Dimensioning |

| Used standard for dimensioning | |

| Design documents, including an element plan | |

| Installation details | |

| Durability and loading—standard of measuring | |

| Lifting system | |

| Strength category | |

| Components inside the component | |

| Connections | Design documents of connections |

| Connection technology (standards) | |

| Information of connection: deconstructable, reusable, non-reusable | |

| Producer of connecting products | |

| Strand reinforcement | |

| Adjoining components | Adjoining structure (for example surface casting) |

| Adjoining materials (surface materials, filler etc) | |

| BIM | As-built model |

| As-maintained model | |

| Material | Material certificates |

| Material information | |

| Use-phase | Operating conditions (inside/outside) |

| Adjustments and repairs made during the use | |

| New holes and surfaces (made after production) | |

| Subsequent use -phase | Assessment of components' condition such as cracks and integrity |

| Assessment of components' safety factor | |

| Condition of connecting products |

The information required to be collected to enable the reuse of DfD concrete components is mainly concerned with general and physical information about these components as well as material issues. However, also information about connections and adjoining components were highlighted, as these matters play an important role in the disassembly process. In addition, it can be significant data concerning the use-phase and information related to the subsequent phase, from the initially produced data. This data related to the use-phase is information gathered during the use, whereas information regarding subsequent use concerns data obtained to ensure the suitability and safety of a component before the subsequent phase. Therefore, this information, classified into these two categories, cannot yet be produced in the design phase of first construction.

4.2. Stakeholders of the data process

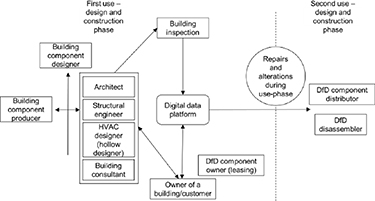

Another task for the participants was to consider the stakeholders who should be involved in the process of entering, managing, and owning the data of DfD components. The visual representation the participants created, translated in English and transformed in digital form, is presented in picture 1. The arrows in the picture represent connections and information flow between stakeholders.

Picture 1. Stakeholders of DfD concrete component process.

Download figure:

Standard image High-resolution imageThe following stakeholders were mentioned:

- element designer

- architect

- structural engineer

- HVAC designer

- owner of the building

- building consultant

- DfD component owner /producer/leasing

- DfD component distributor

- DfD disassembler.

The participants of the workshop proposed that the DfD component producer provides the general information of DfD components. The designer utilizes this information and produces a BIM as well as other information concerning connections and construction. All the information should be saved by the building owner. However, some of this information would also be saved in a building inspection database. There was a mutual consensus among the participants on the need for a cooperative platform for sharing information of buildings, including DfD components, for stakeholders. A digital data platform of the built environment is already in preparation, at the national level, and the participants supported the idea of linking these platforms together. According to the workshop participants, each DfD element should have an ID, identifying information of the dimensions and other focal characteristics that could enable searching for available and suitable elements from the database for subsequent use.

5. Discussion

The participants of the workshop were asked to consider information required to be collected and stored with the aim of enabling the reuse of DfD concrete components. Mainly, this information, including material characteristics, dimensions, standards, and disassembly options, was parallel with the information presented in material passports and banks, in literature. The results were also rather similar with documentation details and other information presented supporting DfD in ISO 20887 standard (ISO 20887 2020). However, due to the specific characteristics of concrete components, also new required information enabling the reuse of DfD concrete components was found. This included connecting materials, such as surface casting or floor covering. Also, connections, which were mentioned in ISO standards (ISO 20887 2020) but not in material banks or passports, was emphasized. In addition, assessment of the condition of DfD components and connecting products were highlighted as producing important data for the market for reused DfD components, including the number of usable products. Furthermore, physical characteristics closely related to concrete components, such as the lifting system and the components inside elements, were highlighted. This extensive information, gathered in the workshop, can be considered as creating the requirements of the data to be collected and stored of DfD concrete elements to enable their reuse. Furthermore, it may provide material passport or material bank database items of DfD concrete components. Even though most of this data can be stored in BIM, alterations made during lifecycle and condition information might be challenging to add to BIM later as a worker who has no access or who is not capable of updating BIM, typically, gathers this data.

In the workshop, it was also pointed out that the current information produced about concrete, including element design and plan, largely meet the needs for information facilitating reuse. Furthermore, it was considered that additional details to this data, including information of modifications and repairs during the lifecycle, might not produce added value for reuse, as the components need to be checked and verified anyway before reuse. Hence, updating the data during the use phase was not considered as an essential task. Excluding this data from the required information could facilitate the use and market development of DfD components, since facility managers or building owners rarely have the capability to update building information, especially in a BIM (Dixit et al 2019). The participants in the workshop pointed out the importance of addressing information related to components' capability and other functional data to enable reuse, which supports the findings of Yeoh et al (2018). On the other hand, Condotta and Zatta (2021) have presented that the reuse of building elements could be more efficient if an element was not expected to maintain the same functional performance as in its 'first life'. Thus, it might be worthwhile to investigate the functional performance of an element on a rough scale, at the subsequent phase, rather than thoroughly by a laborious process.

In the workshop, the use of a component identification code (ID), including information of dimensions and capability, was suggested. This could facilitate the development of a market for DfD components since products with specific characteristics could be easier to find with this coding system. These codes could be added on the digital platform, administered by building inspection, simultaneously with storing structural drawings and other building-specific material. In the context of DfD, also Jayasinghe and Waldmann (2020) have suggested the use of an ID but extend it separately onto project, element, and component levels. In the next few years, the principles of construction legislation will be reformed, at the national level, in the country where this study was carried out. In this reform, it is presented that compilation of a material description, including information of all the materials used in the building, would be required in connection with the application of a building permission. Furthermore, the material description should be offered in a machine-readable form such as a BIM or a table. If this reform is carried out, it would be important to connect the material description with an ID of DfD components or with other DfD component information to facilitate DfD component reuse.

The conversations of the stakeholders and issues related to information gathering and saving, in the workshop, mainly concerned the development of the potential market for DfD components as well as the stakeholders of this market. A digital platform was seen as a focal point and prerequisite for the DfD component market. This digital data platform could operate as a marketplace or as a part of it, later, when the disassembly of buildings with DfD components begins. The results of this study emphasize designers, building owners, and DfD component producers, owners, distributors, and disassemblers as important actors of data processing. These stakeholders are partially parallel with the actors of resources management in circular construction Campioli et al (2018) have presented in their study, and with the stakeholders Çetin et al (2023) have identifies as the users of material passport for existing buildings in social housing contex. However, as our study highlights actors related to DfD, the study of Campioli et al (2018) also points out facility managers, contractors, and policy makers, and Çetin et al (2023) maintenance teams which were not connected with DfD data processing in our study.

To our knowledge, this is the first study that provides information demands of concrete components to enable their reuse. Similar kind of data, supporting component reuse, has been presented earlier, for example, by Cai and Waldmann (2019) and Iacovidou and Purnell (2017). However, these data introduce the information of components at a general level but do not concern the particular characteristics of concrete elements. Even though the results of this study can be considered as initial information for promoting the use of DfD, especially in the concrete industry, the study also has limitations. The outcomes were generated in a workshop with nine experts of the building and concrete component sectors. No representative of potential user or storing organization of components, no building inspection representative, and only one structural designer attended the workshop. Thus, the results may not represent the views of all the stakeholders of a building project comprehensively.

6. Conclusions

To achieve the climate targets, significant actions to reduce the emissions of the construction industry are needed. Since concrete is the most commonly used material in the sector, more actions are required to consider also concrete structures. As a potential strategy for reducing the negative environmental impacts of the construction sector, reuse of components is presented. However, since it has been noticed that current concrete components are poorly suited for reuse (Densley Tingley 2012, Mattaraia et al 2023), new components need to be designed for disassembly. To avoid some of the current challenges considering the reuse of concrete components as well as in order to promote DfD, more knowledge about the information linked with DfD concrete components is required. Thus, this study investigated the data required of DfD prefabricated concrete components to enable their reuse. Furthermore, the stakeholders of this data entering, managing, and storing process were also discovered. In this study, a workshop with experts of the building and concrete component sectors was used as the research method.

The results show that, mainly, the data enabling concrete component reuse is already commonly produced. This data contains the element design plan, the producer, as well as information on connections and adjoining materials and components. Even though this information is typically already created, it should also be easy to track with the purpose of searching for suitable components in the subsequent phases. To facilitate this, it was suggested that a component ID be used, containing general, physical, and material information of components as well as connection types and adjoining components.

The workshop participants found a digital data platform, in which the data could be saved, as the focal point of DfD concrete component reuse. This database could be connected with the information system of building inspections. Thus, all the data enabling the reuse of components would be saved in one platform, and this information could also be exploited for marketing purposes, later, when buildings composed of DfD components are nearing the end of their lifetime. Hence, development of the platform, gathering component data and building inspection information, is the next step needed for enabling creation of market of DfD components in future.

The results presented in this study may enhance understanding of the information required to be saved to enable the reuse of DfD concrete components. This information might be beneficial especially to stakeholders of building projects composed of DfD components, as well as to producers of DfD concrete components and element connections. Increased knowledge of this theme, as well as better understanding of stakeholders in this process, might support the development of DfD concrete components for the market. In the long term, promoting the DfD concept could help tackling the construction sectors' adverse effects on the environment.

Acknowledgments

This work was supported by Business Finland, Parma Oy, Peikko Group Oy, Sweco Finland Oy, Helsinki city and Tampere city through the DfD ecosystem project [Grant Number BFRK/8839/31/2022]. We thank all the participants of the workshop for their generous cooperation.

Data availability statement

The data cannot be made publicly available upon publication because they are not available in a format that is sufficiently accessible or reusable by other researchers. The data that support the findings of this study are available upon reasonable request from the authors.